Forming Challenges and Solutions in Stamping High-Strength Steel

High-strength steel exhibits significantly different behavior compared to conventional low-strength steel during stamping. The associated forming difficulties have become key concerns in die development and production control.

Table of Contents

1. Significant Increase in Forming Load

The higher yield strength of high-strength steel leads to a notable increase in the load required for plastic deformation. When processed on standard stamping equipment, issues such as press capacity reaching its limit, insufficient energy, and inadequate machine rigidity are commonly observed. Localized deformation of dies and rebound of pads may also occur, negatively impacting part quality and dimensional stability.

Countermeasures:

2. Dimensional Inaccuracy Due to Elastic Recovery

High-strength steel shows substantial elastic recovery after unloading, particularly in bending and flanging operations. This makes it difficult to precisely control final part geometry and often leads to cumulative deviations in welding or assembly alignment.

Countermeasures:

3. Edge Cracking Tendency

Due to the lower elongation of high-strength steel, strain concentration at trimmed edges becomes more severe. Conventional shearing processes often introduce microcracks at the edge, which propagate during subsequent flanging or deep drawing, resulting in fracture.

Countermeasures:

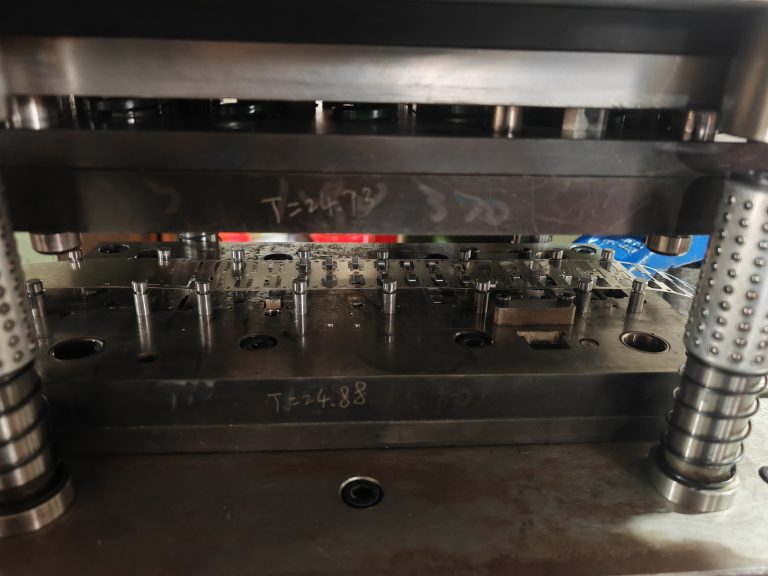

4. Die Wear and Surface Damage

The higher hardness of high-strength steel subjects dies to increased friction and wear, particularly in high-contact-stress zones such as draw beads and flanging radii. Over time, adhesive wear, galling, and surface damage may occur.

Countermeasures: