Metal Stamping Quality Control Tools And Technologies

Table of Contents

Key QA Technologies and Equipment

Metaco is equipped with state-of-the-art QA technologies:

Statistical Process Control (SPC) Systems monitor manufacturing processes, providing critical data for quality control.

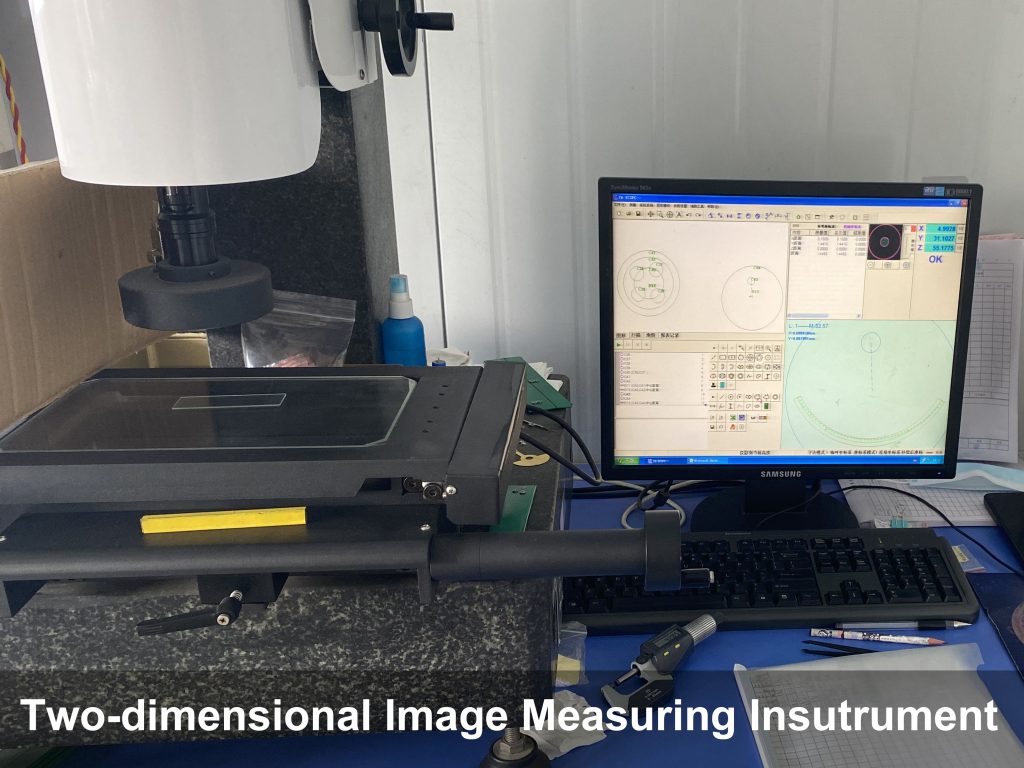

Optical Vision Systems and 2-axis optical comparators offer precise measurements of parts, ensuring they meet specified dimensions.

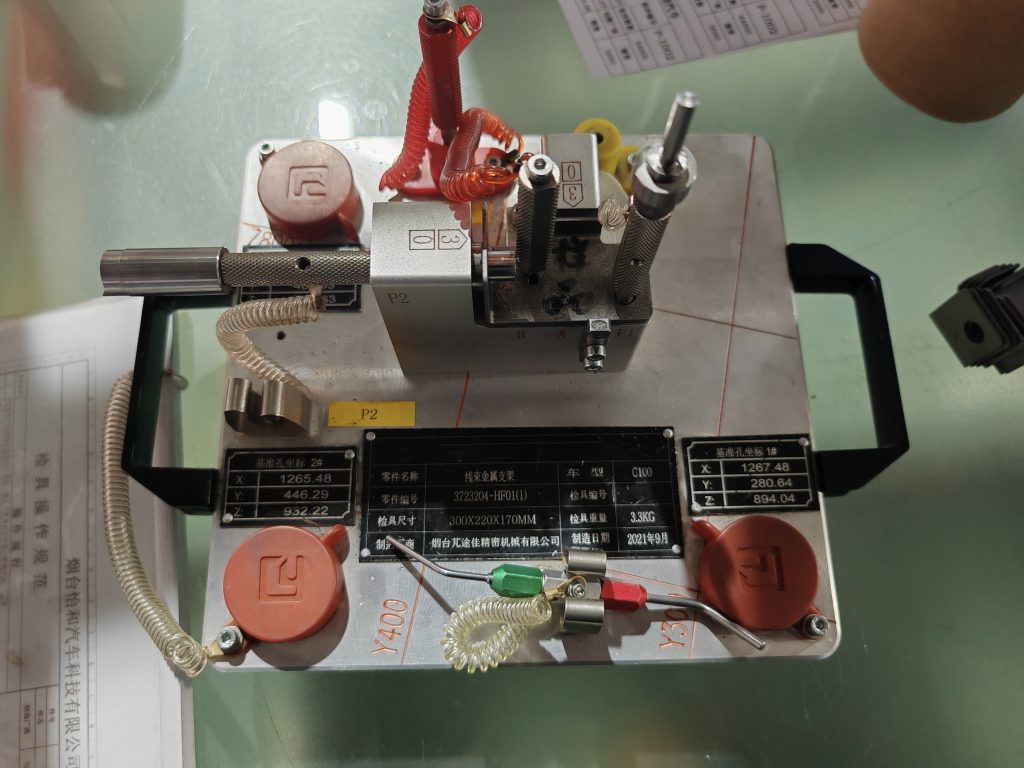

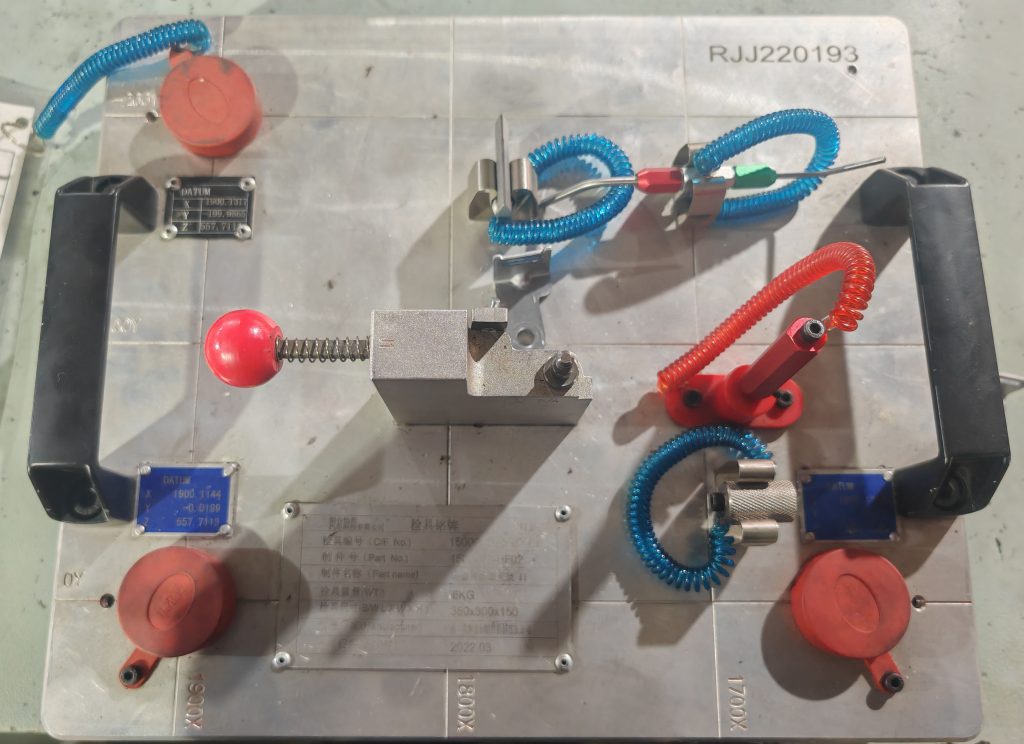

Functional and Custom Gauges are utilized for immediate verification of parts’ fitness for assembly and operational functionality.

Digital Measuring Machines with Metrology Software enhance accuracy and efficiency, providing detailed control over the measurement process.

Coordinate Measuring Machines (CMM) and Reverse Engineering CAD Software support the precise measurement and replication of complex parts, guaranteeing the highest standards of quality.

Our Commitment to Quality

At our factory, the collaboration between quality engineers, inspectors, and tooling developers underscores our holistic approach to quality assurance. Our use of advanced QA equipment, including CNC 2 Axis Optical Comparators, Digital Height Gauges, and Metrology Software, underlines our dedication to precision. Our adherence to IATF 16949:2016 standards, exemplifies our unwavering commitment to delivering superior metal stamping services and products to our international clientele.

Through these QA processes and state-of-the-art technologies, we not only ensure the precision of our metal stamped parts but also reinforce our commitment to meeting the complex needs of our customers across various industries. This dedication to quality and customer satisfaction positions us as a trusted partner for businesses looking for high-quality, customized metal parts for export sales.