Prototyping Successes

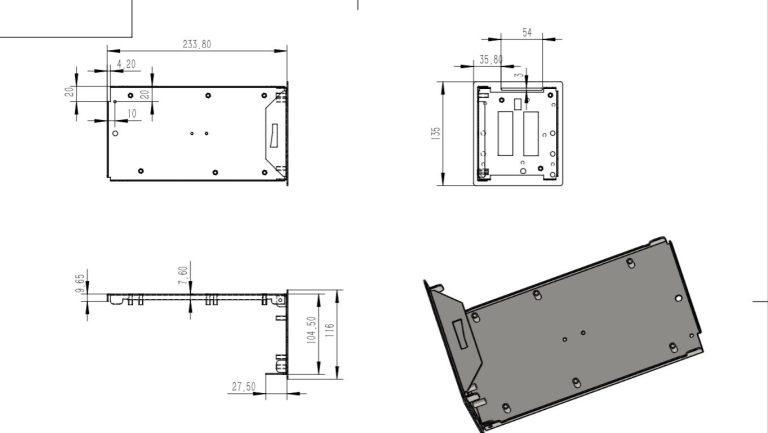

Pruduct: Sheet Metal PCB Frame

Process: Laser cutting, Bending, Welding, Riveting, Polishing

Customized By U.S. Customer

About two years ago, our customer reqeusted for a custom sheet metal PCB frame with small quantity. Instead of a complete drawing, what we got was several pictures with illustrated dimensions and intended revises. Besides the illustrated pictures, there were even ideas could only be descrbied.

With our understanding and experience in sheet metal fabrication, our technician finalized the drawing and shared with customer. After one round of sampling, the design was confirmed.

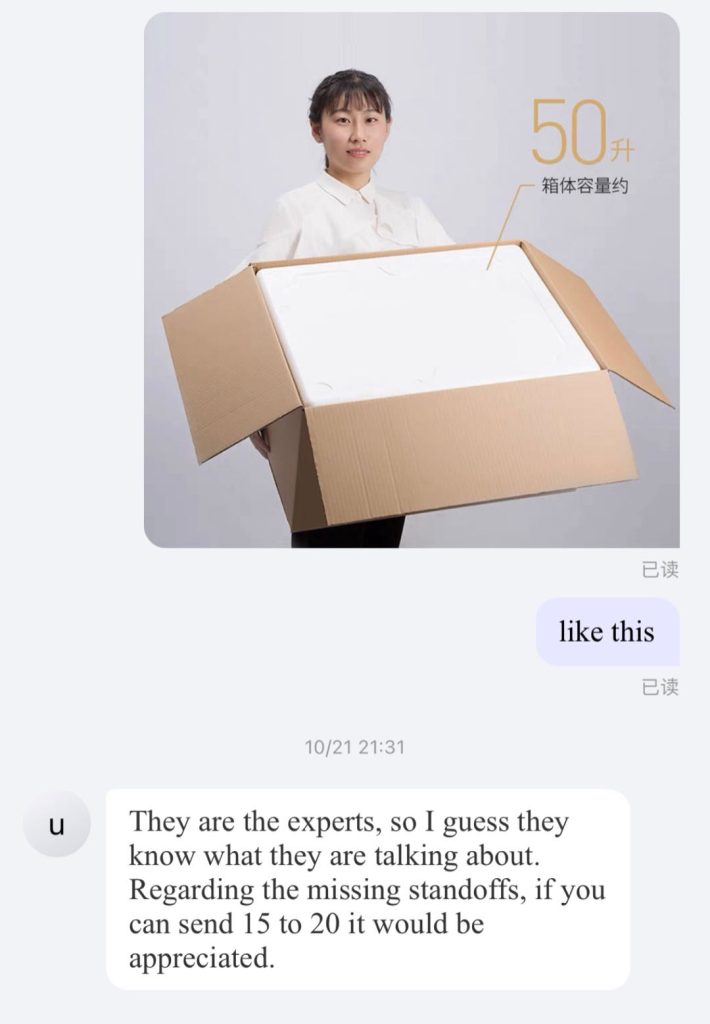

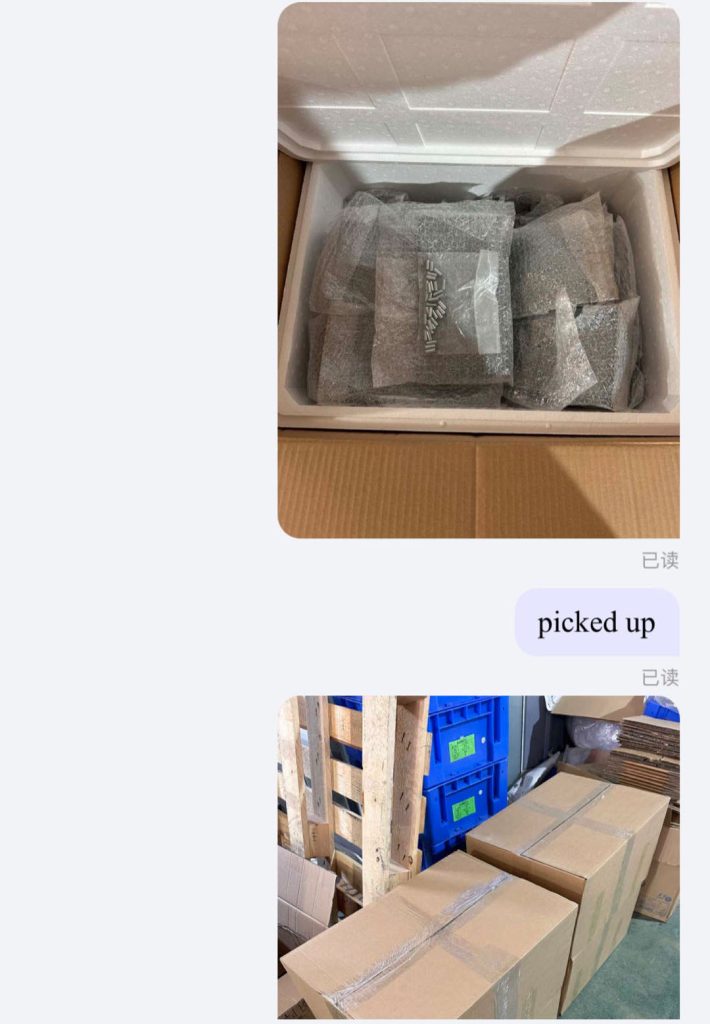

This product is repeat order at small volume. It took rounds of trial to find the balance between time efficiency and cost efficiency. We tried shipping with express, mail and sea-land transportation. Even with single bubble package and then carton, the problem of damage happens. Finally, we invented the EP box package, which is light and solid while meeting the requirement of sea-land shipping. With customer’s feedback and out consistent searching, we finally found the balance between cost efficiency and product safety.

Metaco would like to say thank you to our customer for patience. The key of our growth is we care our customer’s satisfaction and one of the tools is sufficient communication that we insist and specialize.