OEM Metal Fabrication

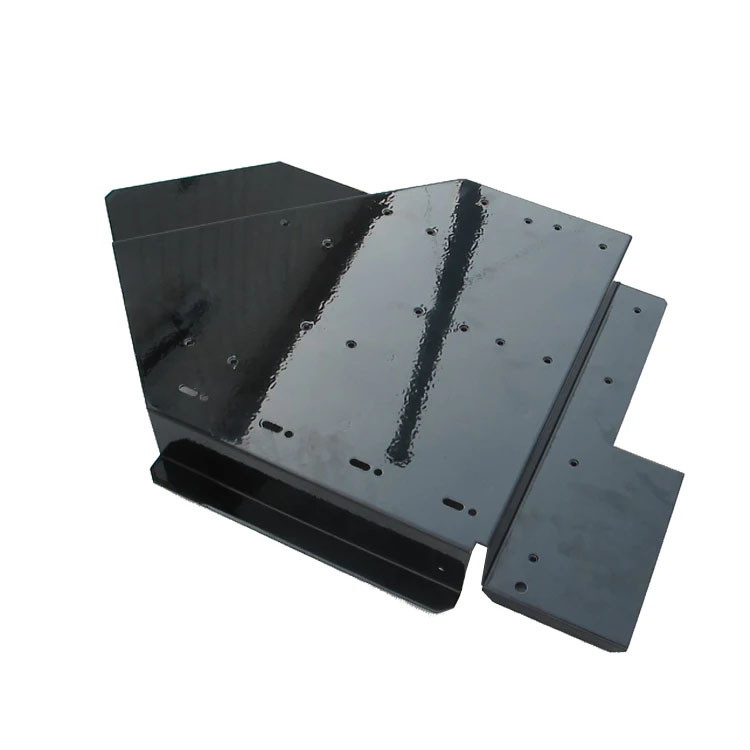

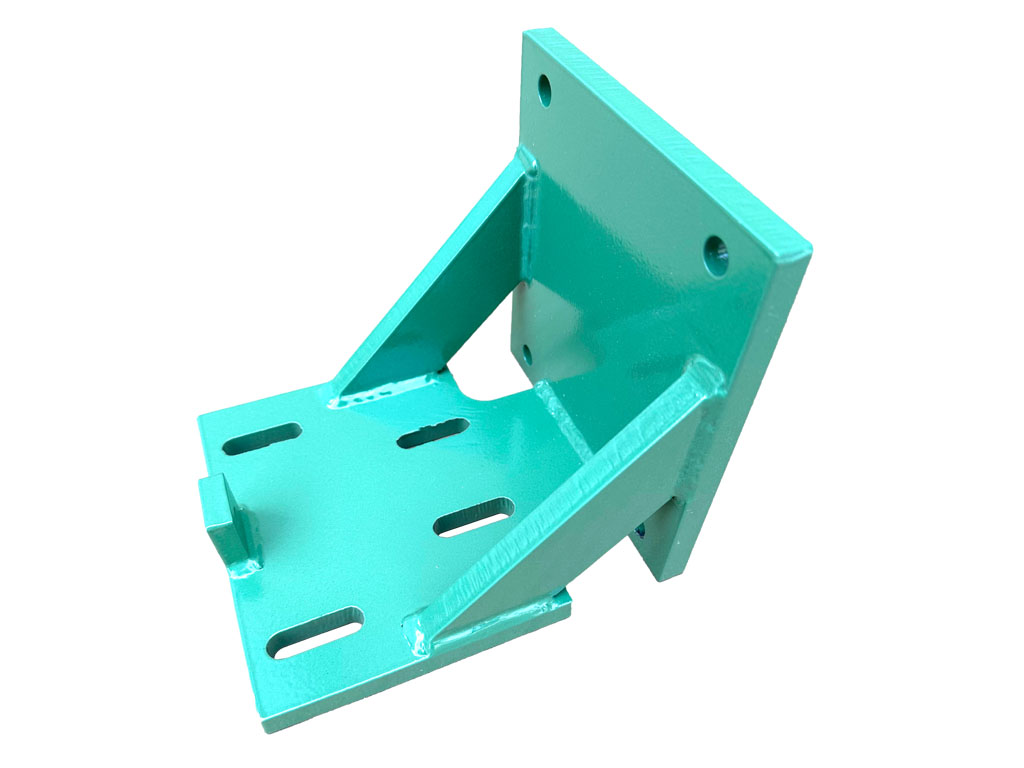

We are a manufacturing-oriented factory that provides OEM metal fabrication services, specializing in customized production based on customer drawings or samples. Our core businesses include sheet metal fabrication, stamping, OEM welding and assembly, as well as machined parts manufacturing. We support everything from single-piece prototyping to large-scale continuous production. We have long provided supporting OEM services for equipment manufacturers, electrical control industries, and clients requiring various mechanical structural components, with full capabilities from small-batch trial production to long-term mass supply.

OEM Metal Fabrication Capability

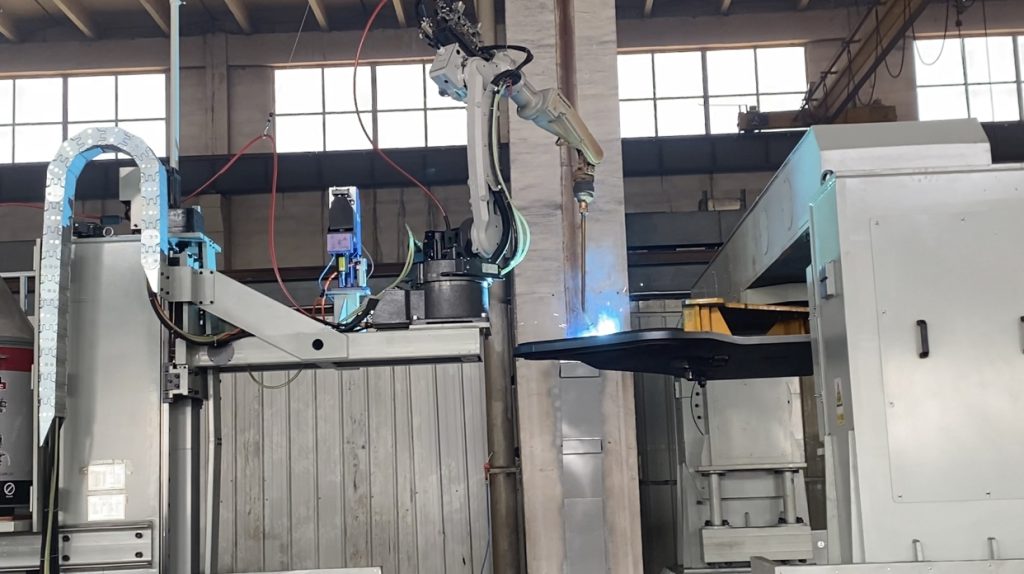

We are equipped with a complete metal fabrication production line, covering processes such as sheet metal cutting, stamping, bending, welding, grinding, coating, and machining.

Major equipment includes laser cutting machines, CNC bending machines, presses, MIG/TIG welding stations, CNC lathes, and vertical machining centers. The factory can handle both precision sheet metal and structural component production tasks.

OEM Metal Fabrication Workflow

The typical workflow begins with drawing import or sample analysis, followed by manufacturability evaluation by our engineering team. Once confirmed, the process proceeds to material layout, sampling, and batch production. We can adjust the process structure based on customer needs, such as simplifying weld points, reducing the number of assembly components, or modifying material thickness to optimize cost or improve processing efficiency.

OEM Metal Prototyping

We are not limited to drawing-based manufacturing. At the early stage of the project, our engineers can assist with drawing review, structural evaluation, material substitution suggestions, and other technical support. If customers only provide 2D drawings or PDFs, we can reconstruct the structure as needed. For welded and assembled products, we can perform assembly verification and assist customers in establishing assembly benchmarks and workflow standards.

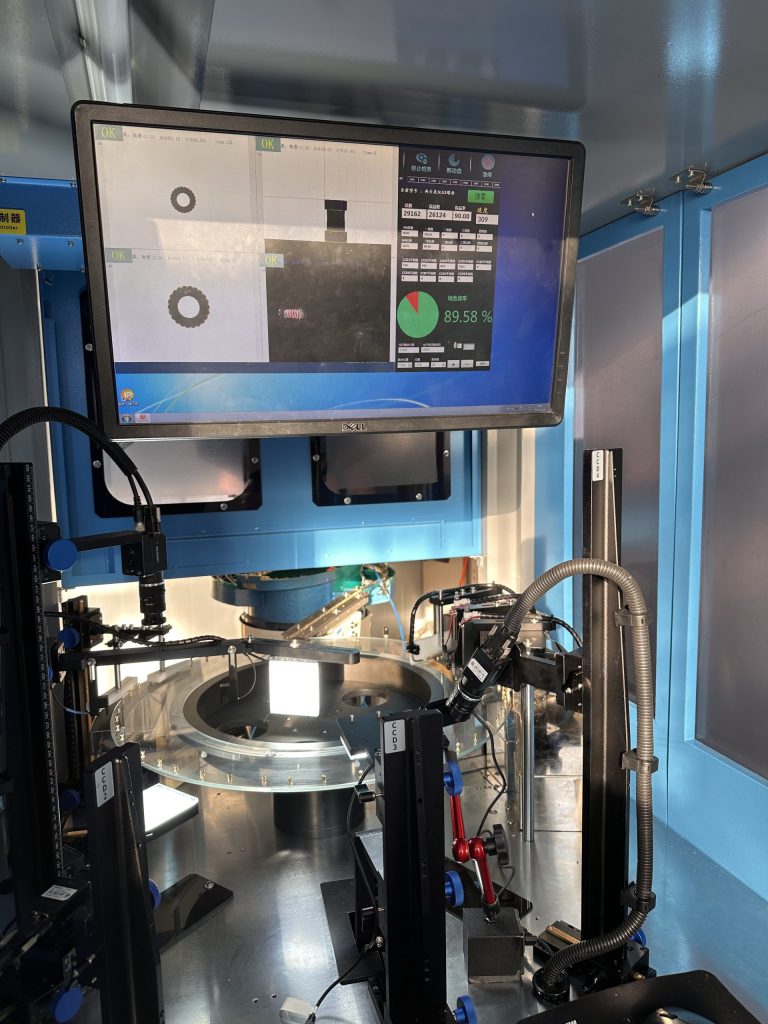

OEM Metal Fabrication Quality Control

Quality control is a key aspect of our manufacturing process. We have a comprehensive control system covering incoming material inspection, in-process sampling, assembly inspection, and final shipment checks. The workshop is equipped with standard measuring tools such as calipers, micrometers, height gauges, hardness testers, and coordinate measuring machines (CMMs).