TS16949 Certified Stamping Factory

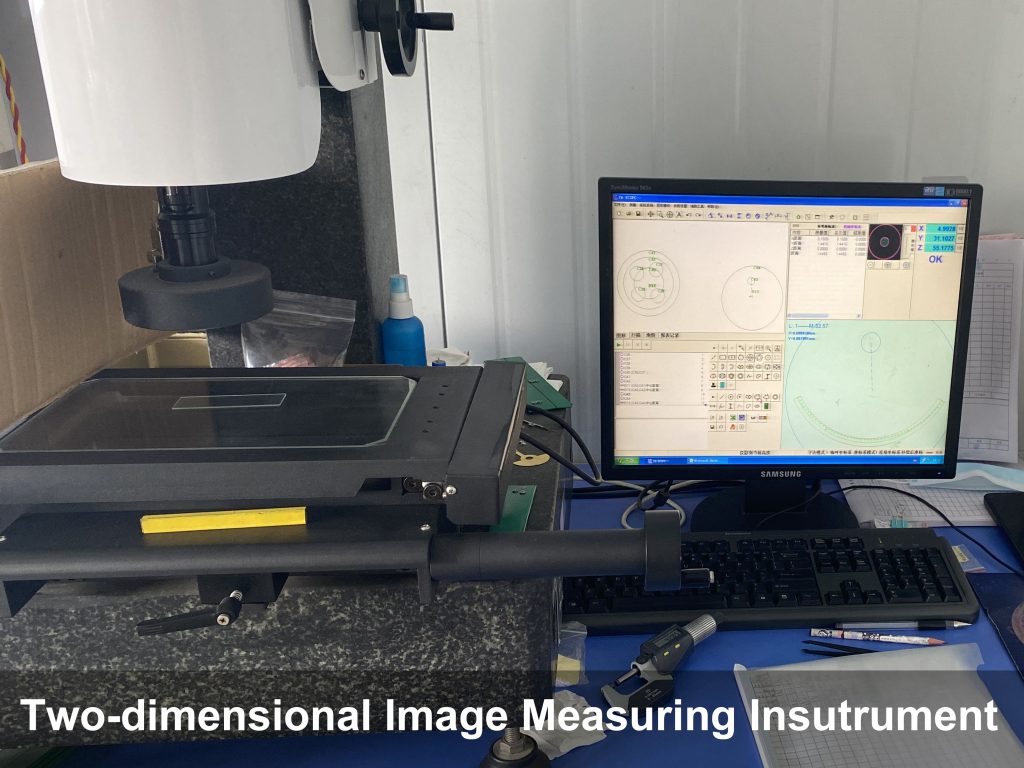

To ensure that every product leaving our facility meets the strictest quality requirements, our quality control process ensures that every step of production is meticulously monitored, and we strive to exceed our customers’ expectations by focusing on precision and attention to detail.

Initial Inspection Of Materials

In-Process Inspection

SPC

Final Inspection

Quality Assurance Documentation

Certifications And Compliance