Comprehensive Welding Service

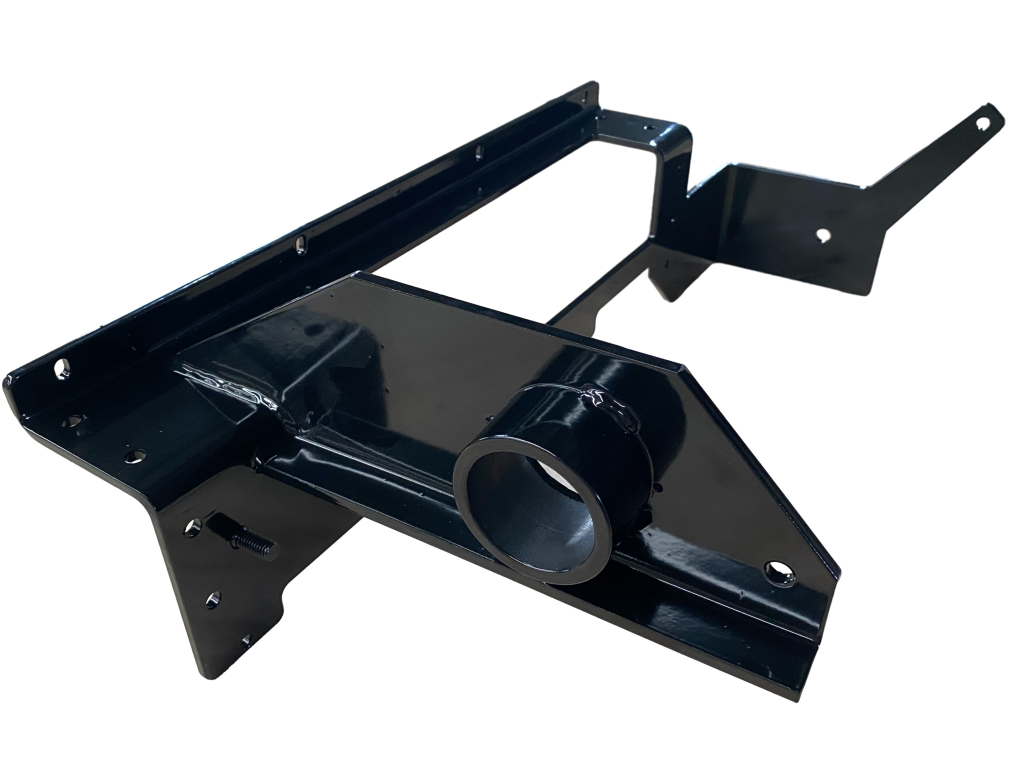

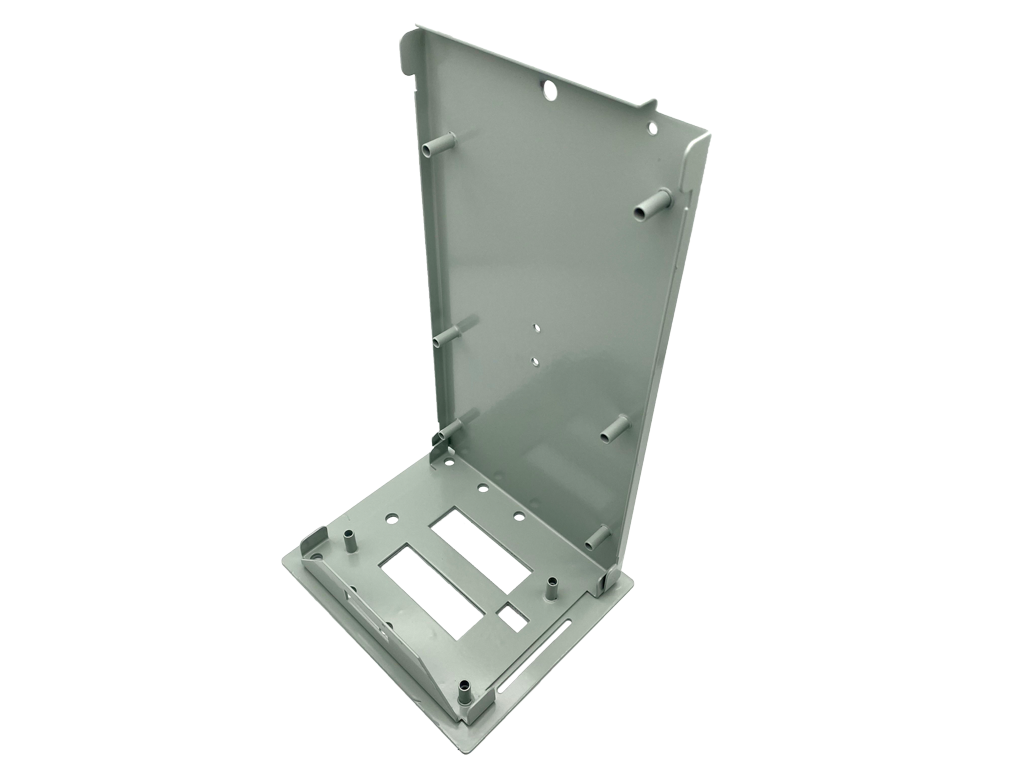

One-Stop Metal Processing Services

We are a professional metal processing factory specializing in welding, complemented by laser cutting, bending, wire cutting, engraving, milling, spraying, and other processing services. Our focus is to provide a comprehensive, efficient, one-stop metal processing solution. We strive not only to perfect our welding expertise but also to fulfill customers’ needs for complete part processing through a diverse range of services.

Welding Capabilities Overview

TIG Welding

TIG welding suits thin metals and high demands for weld seams. The weld surface is smooth and defect-free.

Advantages:

1. Precise welding with minimal heat impact, especially effective for stainless steel and aluminum alloys.

2. Our shielding gas technology ensures high-quality welds.

MIG/MAG Welding

MIG/MAG welding is a highly efficient arc welding process used for thick and large metal surfaces.

Advantages:

1. Fast welding speed, suitable for carbon steel, stainless steel, and aluminum alloys.

2. Our digital control systems stabilize MIG welding, reducing welding defects.

Spot Welding

Spot welding is a fast resistance welding process for quickly joining thin sheet metals.

Advantages:

1. Rapid welding speed, perfect for mass production with minimal heat impact.

2. Our optimized current control technology ensures maximum weld strength and stability.

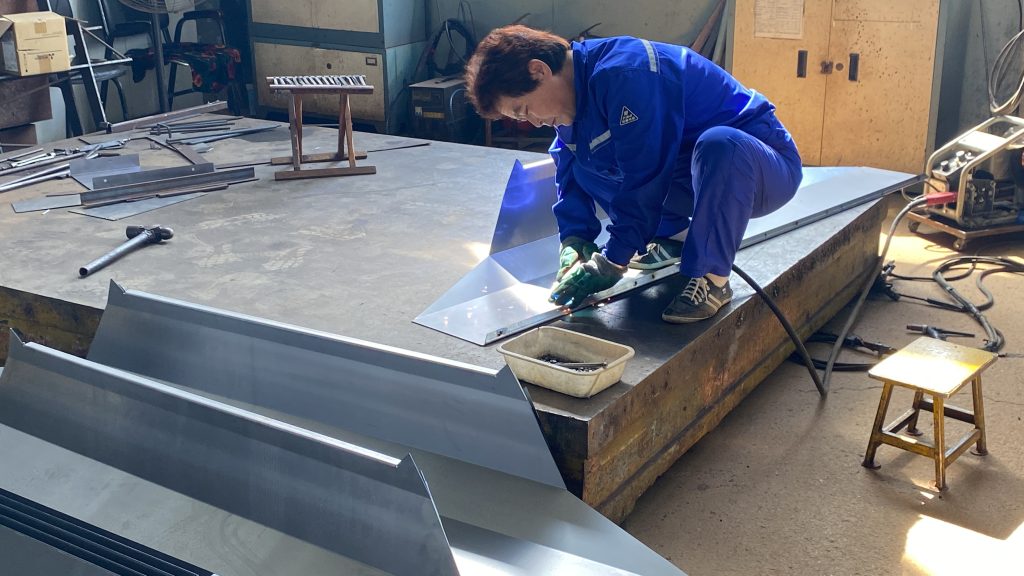

Manual Welding

Manual welding is highly adaptable and suitable for structures that are complex or difficult to access.

Advantages:

1. Flexible in customizing welding plans for specific needs, perfect for complex or on-site welding.

2. Our welders are experienced, trained, and regularly assessed.

Additional Metal Processing Services

While welding is our core focus, we also have capabilities in other areas of metal processing, Our one-stop service allows customers to complete all processes in one place, saving both time and costs.