One-Stop Welding and OEM Solutions

In the manufacturing industry, especially in the non-standard sector, more and more companies tend to look for suppliers who can undertake multiple processes in one place. We are exactly such a company, an integrated processing center that combines welding, sheet metal, machining, and surface treatment.

Whether you need a sample for small batch production or large batch welding parts for stable outsourcing, we can complete it all at once, eliminating the need for multiple contacts.

Metaco’s Service Range

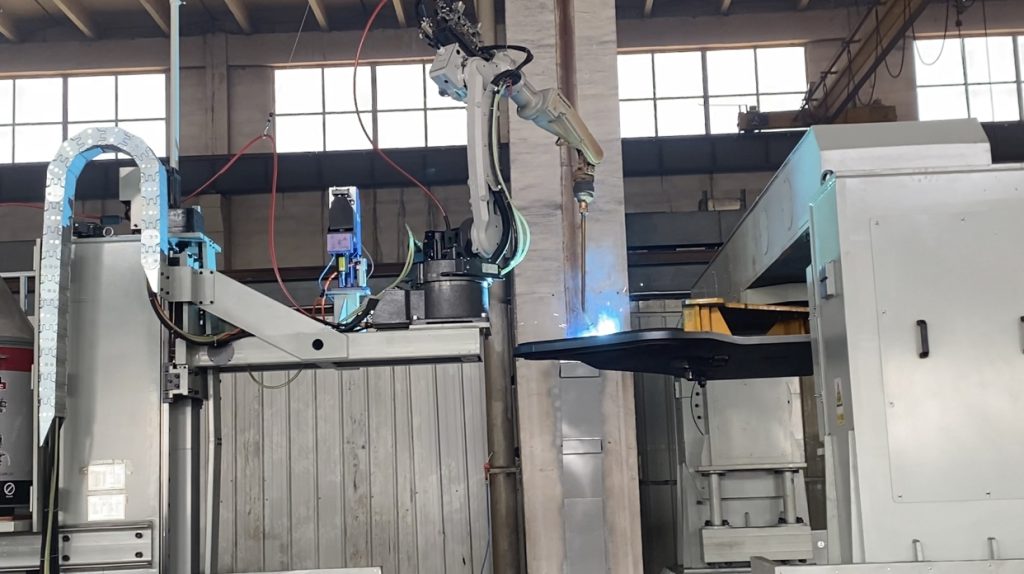

Welding

Manual welding, TIG welding, MIG welding, aluminum welding, and other welding processes.

Laser Cutting

High-precision cutting, supporting materials such as carbon steel, stainless steel, aluminum alloy, etc.

CNC Machining

Supports post-weld machining to ensure dimensional accuracy and assembly requirements.

Bending

Multi-station bending processing, high angle accuracy, and good consistency.

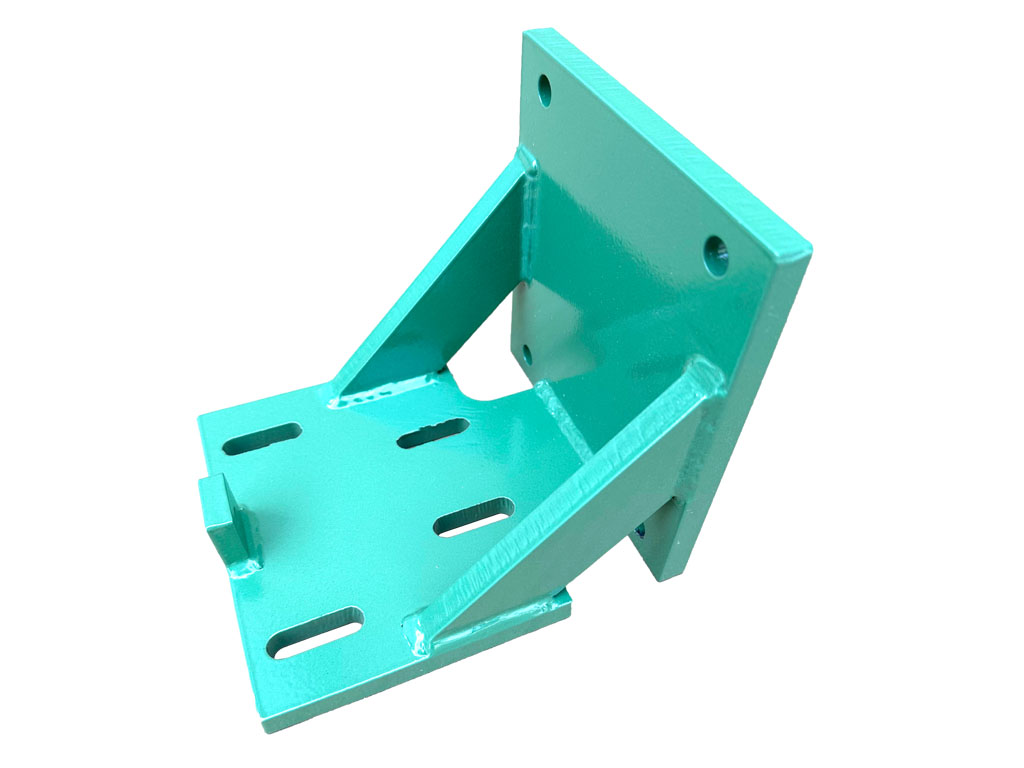

Surface Treatment

Spraying, sandblasting, electrophoresis, powder coating, baking.

Custom Packaging

Includes rust protection and export-grade wooden box packaging.

Welding Outsourcing and Supporting Services

We have been providing welding parts to many automation equipment manufacturers and non-standard machinery companies for many years. Customers provide drawings, and we complete the entire process from material preparation, welding assembly, precision machining, surface treatment, to packaging and delivery.

We support customized processing, sample prototyping, and OEM outsourcing. We understand the complexity of non-standard parts and know how to control quality, optimize processes, and ensure timely delivery.

Whether you need us to weld a specific structural part, or wish to outsource sheet metal, welding, and machining parts all together, we can cooperate to reduce intermediate steps and improve delivery efficiency.

Full-Process Processing Capabilities

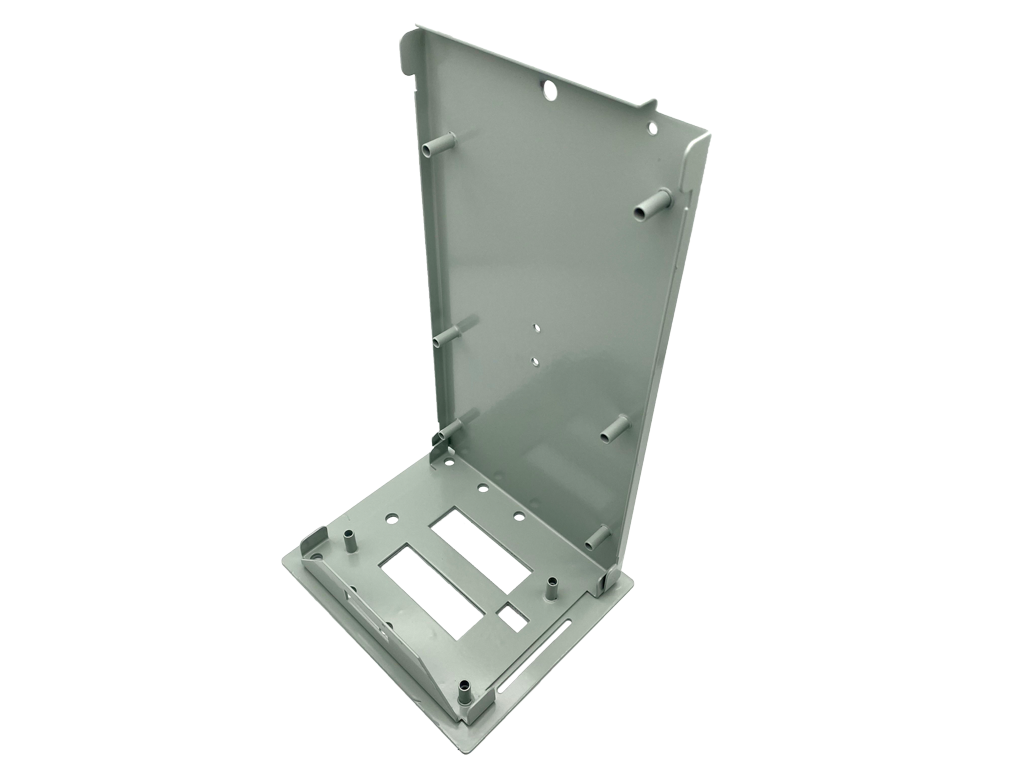

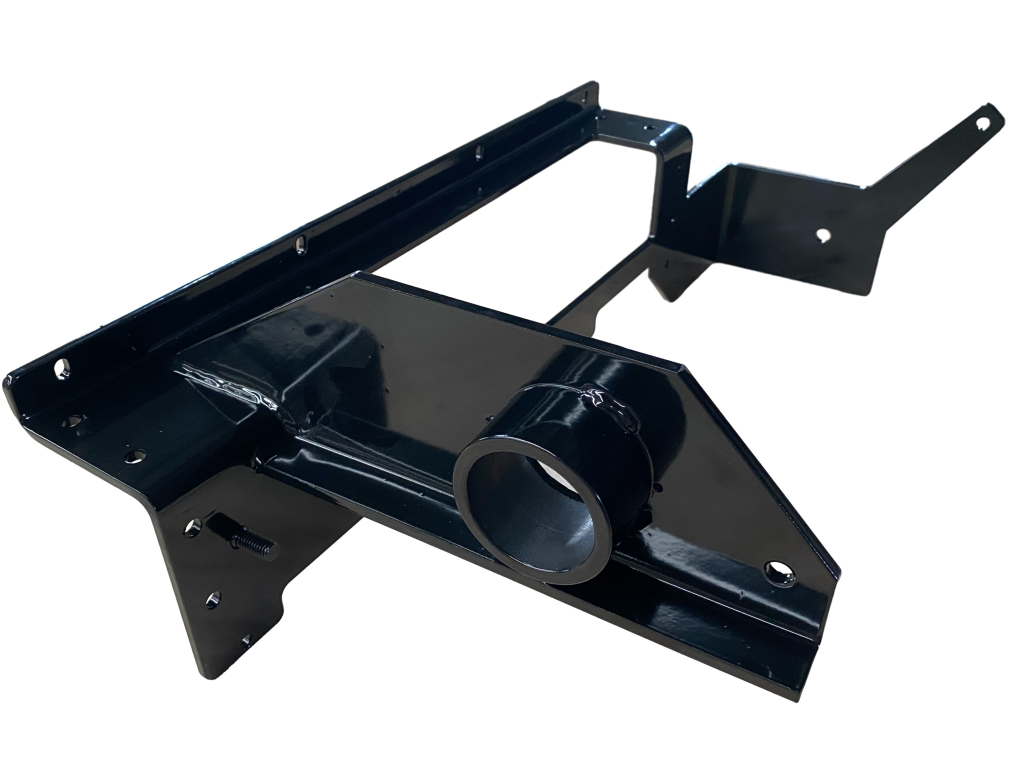

We have a complete sheet metal and welding production line, supporting the processing of various materials and structural components. For common components such as steel structural frames, bases, brackets, flanges, boxes, etc., we have formed stable and mature processes.

For sample prototyping or single-piece trial production projects, we can quickly process the drawings to meet product verification or initial debugging needs. For medium and large batch orders, we ensure consistency and delivery time through the use of jigs and fixtures, multi-station welding areas, and standardized processes.

Types of Orders We Accept

We are skilled in handling both small batch prototyping and large batch outsourcing, understanding the different needs of each project cycle.