Powder Coating

Surface treatment methods for metal parts

Powder coating mainly used in the beautification and protection of sheet metal parts and weldments. In our processing, we pay special attention to this step to ensure the quality and aesthetics of the final product. Before coating, we strictly pre-treat the parts, including cleaning, degreasing, rust removal, etc., to ensure that the coating layer can adhere evenly and firmly to the surface of the parts. For certain specific parts, they can be directly subjected to powder coating after precise cutting. We pay a lot of attention to the quality of appearance, we promise never to compromise by using recycled powder for cost-saving.

Basic process of Powder Coating

Preparation or Pre-treatment

Smearing with chlorine solution and dry it

Applying Powder

Sprays coating powder on weldment

Curing/Cooling and Finishing

Suspend workpiece post-furnace

Color Selection for Powder Coating

Metaco assist our clients in selecting color for their projects. If you have a specific color number, we can precisely match it to your requirements. In cases where a specific color number is not available, we offer the flexibility to mix and match colors according to your needs, using the color palette.

Gloss levels Selection for Coated Surface

We offer a wide range of gloss levels for powder coatings. Choose from flat, matte, semi-gloss and gloss finishes. Flat and matte finishes are non-reflective, semi-gloss finishes have a well-balanced sheen, and our gloss finishes provide maximum reflectivity!

Product display after Powder Coating

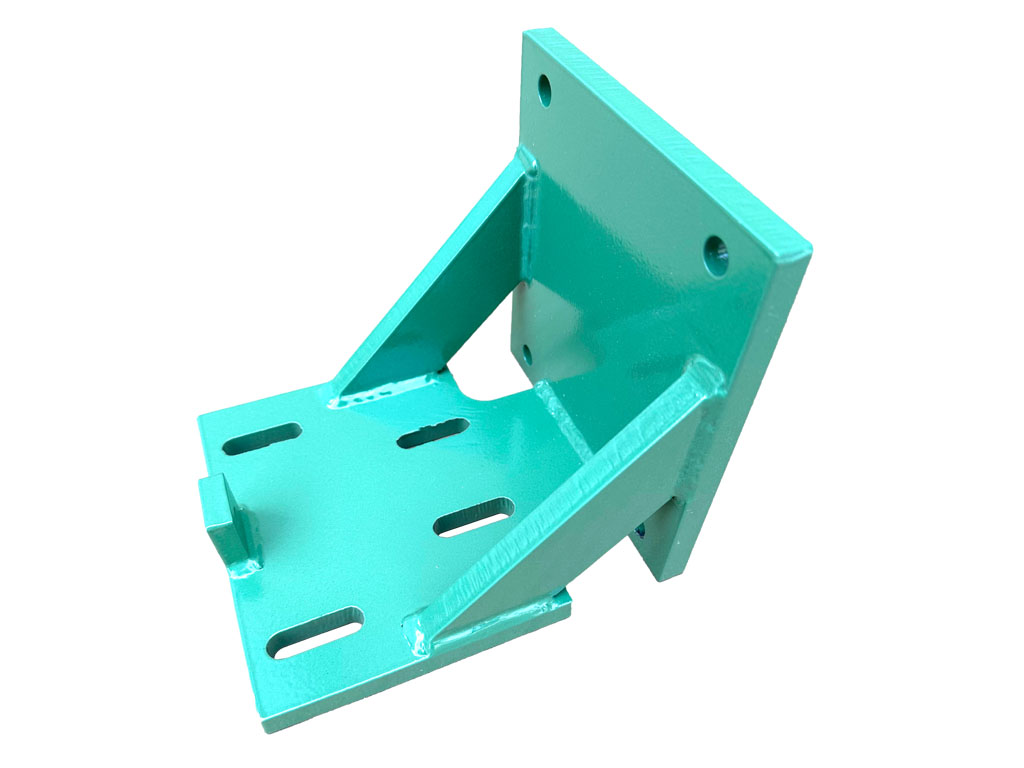

Bracket by laser cutting

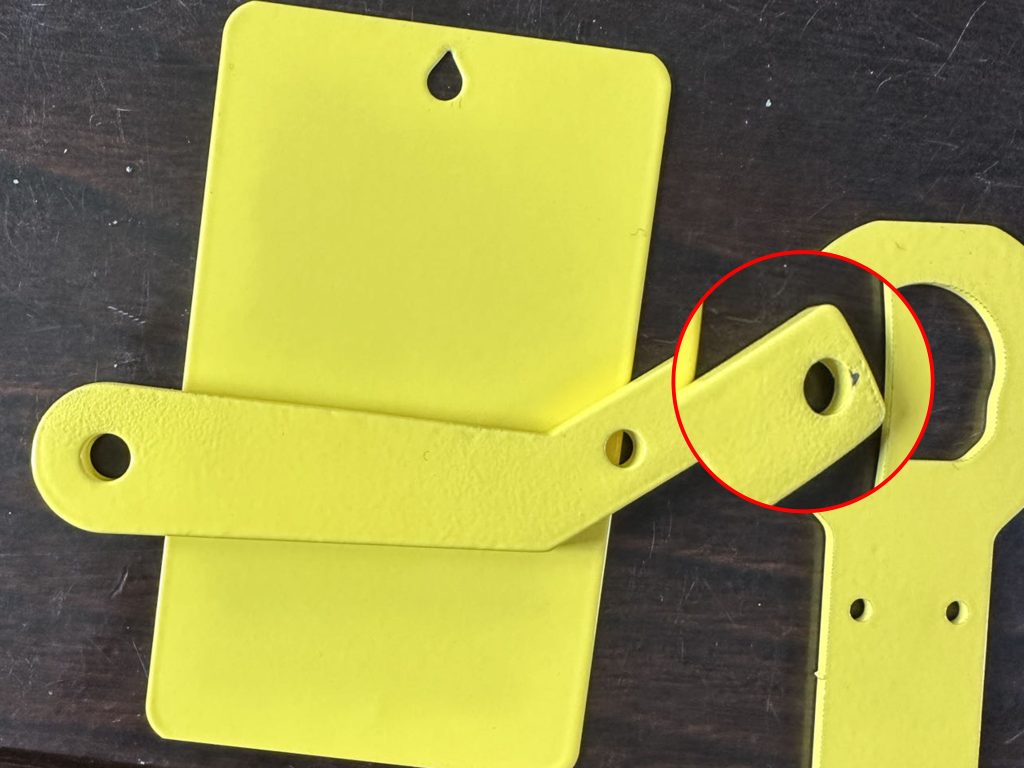

Coating of small workpieces with customized color

Acceptance requirements after Powder Coating

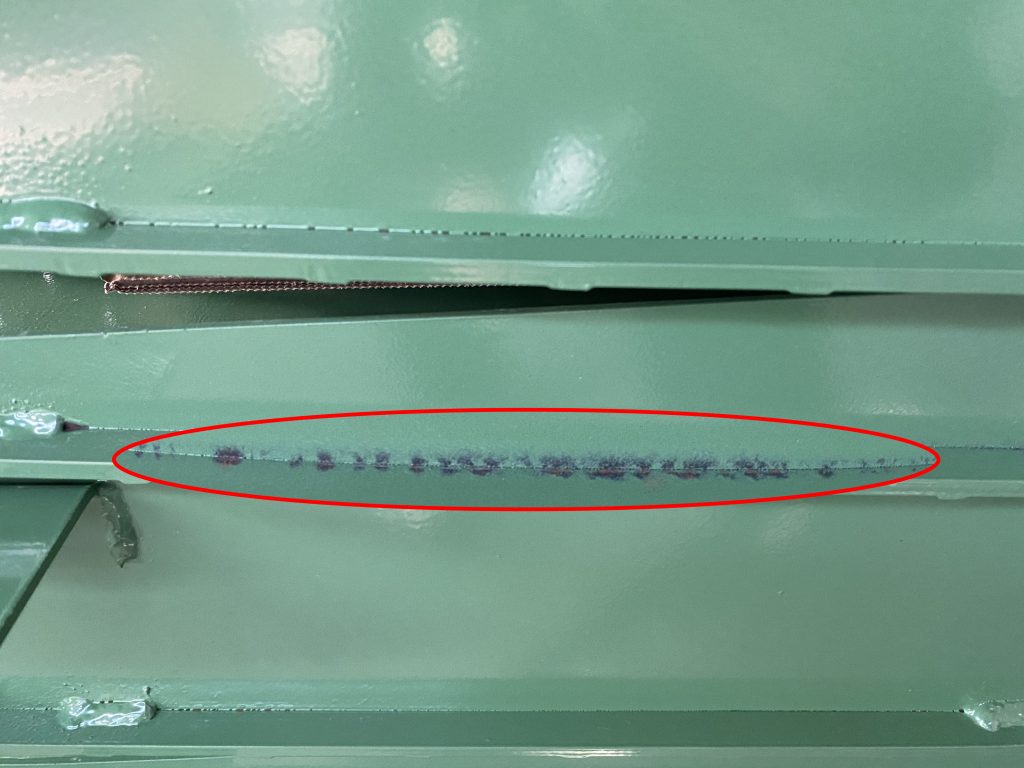

Appearance quality

Be sure that the color of the coating uniform and match the specified shades. And that the surface is free of bumps, drips or irregularities. The coating must not blister, bubble, or flake, and the glossiness of the coating must align with predefined specifications.

Coating Thickness

Ensure that the coating thickness should be consistent across the entire surface, and sufficient coating coverage on edges and corners is crucial.

Key Causes Of Powder Coating Defects