The Galvanizing Flow

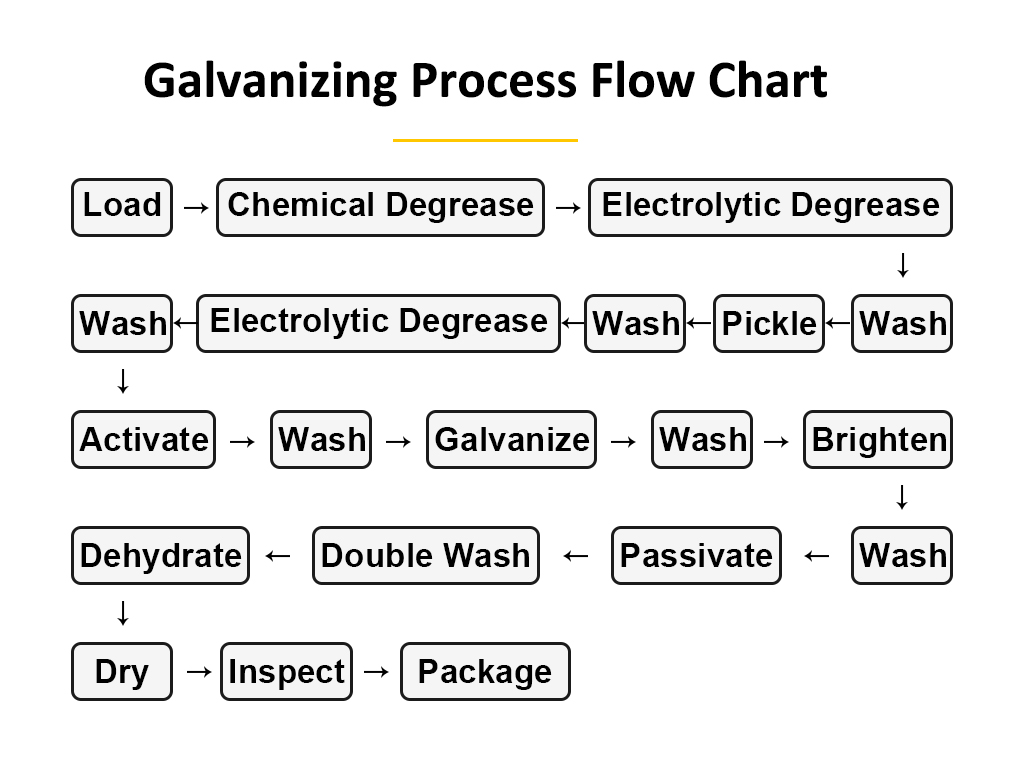

Metaco’s galvanizing process follows an established series of stages to ensure each metal part is properly coated. The process initiates with an alkaline degreasing to remove oils and dirt, followed by water rinsing. Next, acid pickling eliminates rust and scales, succeeded by another rinse to clean the surface. The pre-fluxing stage then prepares the parts for galvanizing, dipping them into the flux solution to prevent oxidation. Subsequently, the parts enter the zinc bath, where they receive a protective zinc coating. Finally, a quenching in water or passivation, and drying, are performed to complete the process. Each step is executed with precision to ensure the finished product meets Metaco’s high-quality standards.

Preparation

Initial Degreasing

Chemical Degreasing

Electrolytic Degreasing

Rinse and Clean

First Water Wash

Surface Conditioning

Acid Pickling

Intermediate Cleaning

Second Water Wash

Second Electrolytic Degreasing

Third Water Wash

Activation and Galvanizing

Activation

Fourth Water Wash

Galvanizing

Fifth Water Wash

Finishing

Brightening (Out Light)

Sixth Water Wash

Passivation

Final Cleaning and Drying

7th & 8th Water Wash

Dehydration

Drying

Quality Control and Packaging

Inspection

Packaging

Stamping and Galvanizing Integration

At Metaco, the integration of stamping and galvanizing processes is central to our operation. As a metal stamping manufacturer, we take responsibility for the surface treatment of our products, ensuring they meet our clients’ requirements for finishes. Most of our stamped parts undergo galvanizing, a capability we’ve refined by selectively partnering with specialized galvanizing providers. The partnership forged and fine-tuned over many years, are key to achieving efficient, high-quality galvanizing for our products.

In our stamping and galvanizing operations, we know that dimensional and other variances can occur after the processes. Such tolerances are an inherent part of post-stamping and galvanizing treatments. Our methodology is meticulously adjusted, allowing for a harmonized interplay between stamping and galvanizing. This fine-tuning aims to predict and minimize these tolerances, ensuring the final product adheres closely to the original design specifications.

Comprehensive Metal Stamping Fabrication

Metaco’s services extend beyond galvanizing to encompass a complete metal stamping fabrication solution. Following the galvanization, parts are dried, inspected, and if required, further processed or assembled according to client specifications. This end-to-end service model is what sets Metaco apart, ensuring that every component delivered meets standards.