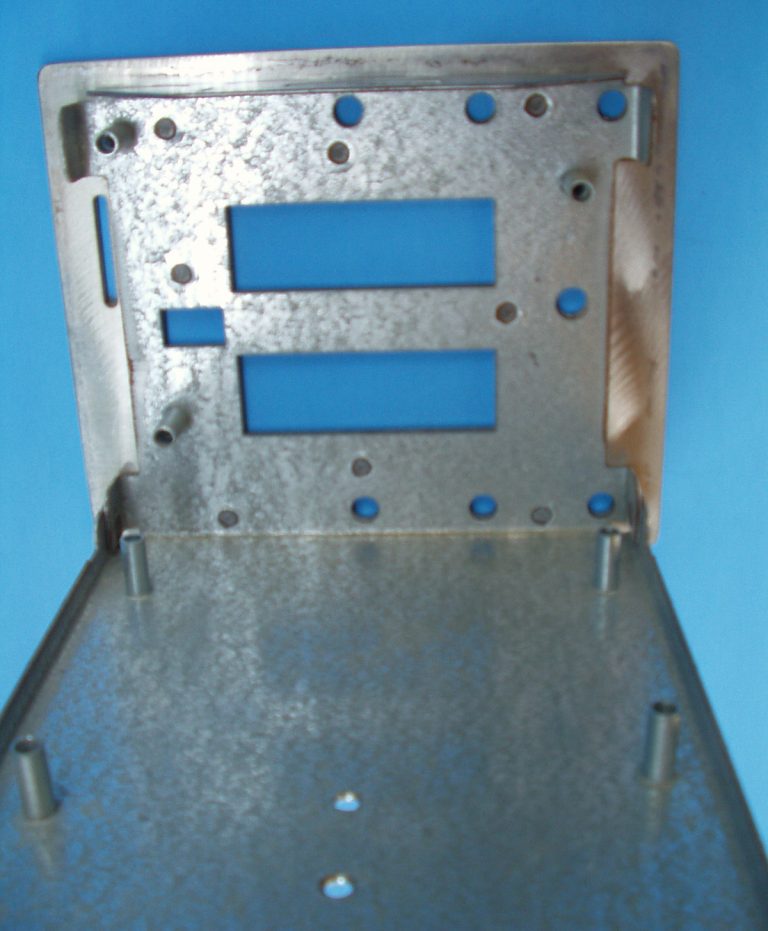

Reverse Engineering for Metal Fabrication

In metal fabrication, there are often instances where creating a part without existing drawings is necessary. This process, known as reverse engineering, is a critical skill for any successful metal fabrication business.

Manufacturing Parts without Drawings

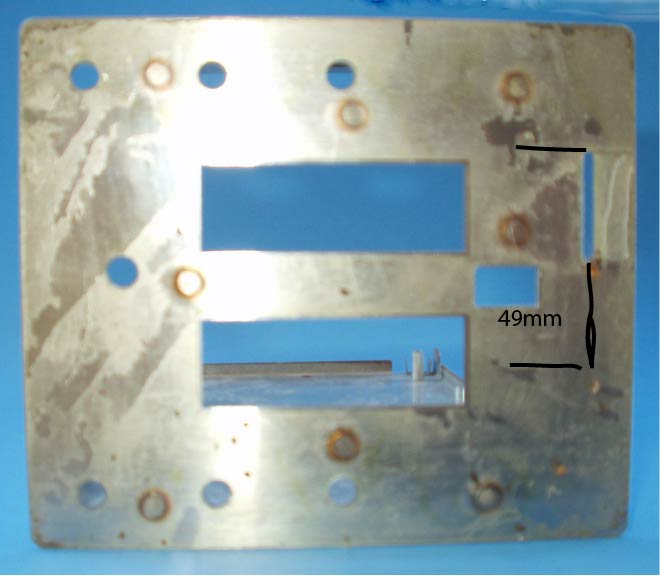

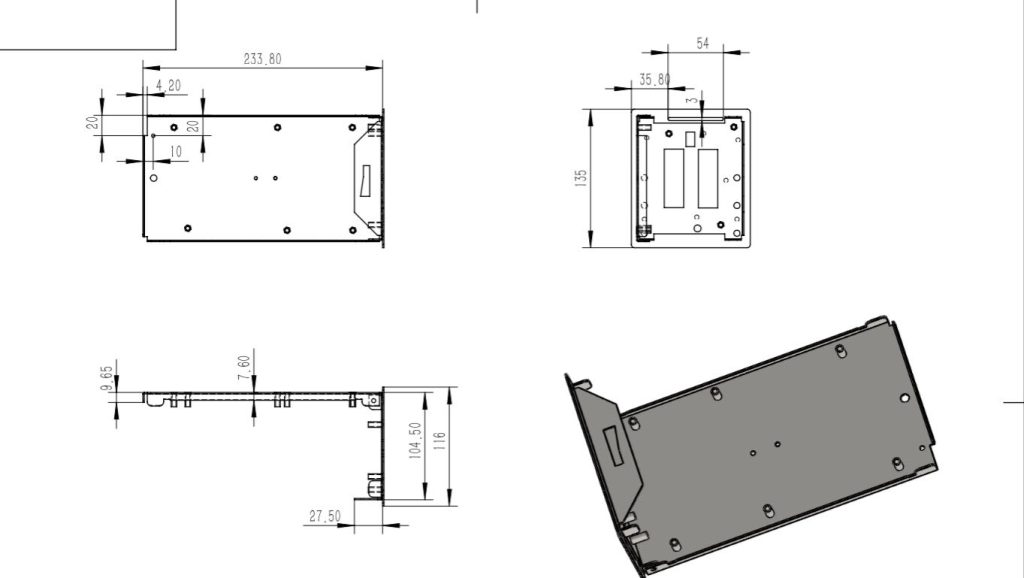

The primary goal of reverse engineering in metal fabrication is to determine the exact dimensions and finalize the design of a part. While measuring the dimensions is often the easier aspect, the true challenge lies in accurately identifying the critical tolerances. Properly accounting for these tolerances is essential for ensuring the part will correctly interface with other components and function seamlessly within the assembly.

Reverse Engineering Standard Parts

When dealing with standard parts, the process is relatively straightforward. By identifying the part code, the corresponding shape, dimensions, and tolerances can be readily determined. For example, when reverse engineering a part that must interface with a bearing, simply referencing the bearing code can provide the necessary information to accurately machine the required hole size and tolerance.

Reverse Engineering Custom Parts

The complexity increases when reverse engineering parts that must connect to custom or proprietary components, such as shafts. In these cases, it is essential to consult directly with the component suppliers to gather the precise dimensional and tolerance specifications. This additional research ensures that the reverse-engineered part will seamlessly integrate with the existing assembly.