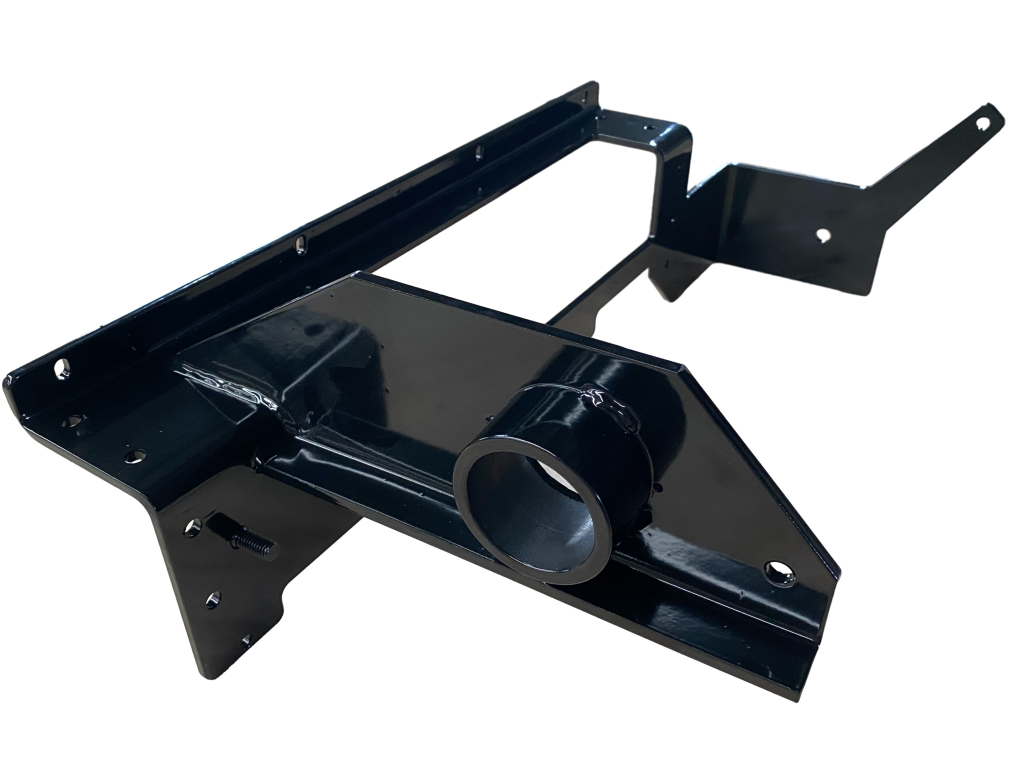

Sheet Metal Assemblies

Sheet metal assembly process

Sheet metal assembly entails integrating the individual parts of a component, precisely positioning each part, and then fastening and connecting them to form a final product that meets the specifications outlined in the drawings.

Correct and well-established assembly processes are crucial for determining the operation methods for each stage of production. This not only maximizes the prevention and reduction of deformation during assembly and welding but also ensures product quality and enhances labor productivity.

Precision In Sheet Metal Assemblies

The diversity of sheet metal components, combined with factors such as factory space, equipment capabilities, the skill levels of operators, and material characteristics, means that there is no single, universal method for assembling sheet metal components. Each production scenario must be carefully considered to determine the most appropriate assembly method.

Sheet metal assembly involves several key stages: assembly, welding (or riveting and other joining methods), alignment, coating, and inspection.

Comprehensive Sheet Metal Assemblies Services

We offer our clients a complete suite of sheet metal work and metal fabrication services, including design and manufacture, supply chain integration, and quality assurance. Our primary focus and expertise lie in manufacturing our clients’ products and sub-assemblies to the highest standards.

Building Lasting Partnerships

Sheet metal assembly entails integrating the individual parts of a component, precisely positioning each part, and then fastening and connecting them to form a final product that meets the specifications outlined in the drawings.

Sheet metal Assemblies by metaco