High Volume Stamping

We define high-volume stamping as producing more than 10,000,000,000 pieces annually. However, managing such high volumes introduces complex challenges. Dies, production processes, materials, inspections, and maintenance are essential for stable high-volume production. Factors like tool wear, management inefficiencies, quality assurance, and operational scheduling can inflate costs and extend production timelines. The capability to undertake high volume stamping production is also a key factor in selecting quality suppliers.

If you need custom high volume stamping parts, please contact us immediately for a quote!

Ensuring High-Quality High Volume Stamping Production

Dies in High Volume Stamping

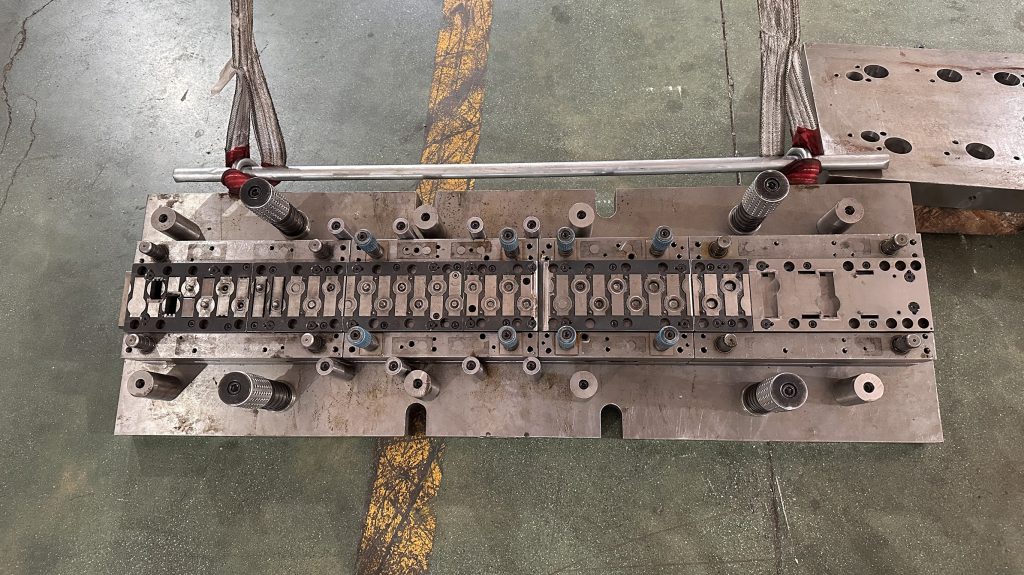

At Metaco, we employ progressive die stamping and compound die stamping to achieve high-speed stamping operations, ensuring precision while minimizing waste and cost. High volume metal stamping demands the use of higher-end components in dies. We frequently use carbide cutting blades and apply special coatings to prolong the lifespan of cutting and forming blades.

Our in-house stamping die team handles design, manufacturing, assembly, and maintenance, streamlining the process to quickly identify and resolve issues. We have established contingency plans and management strategies for die maintenance, speeding up maintenance and improving the operational efficiency of parts.

High Volume Stamping Production Operations

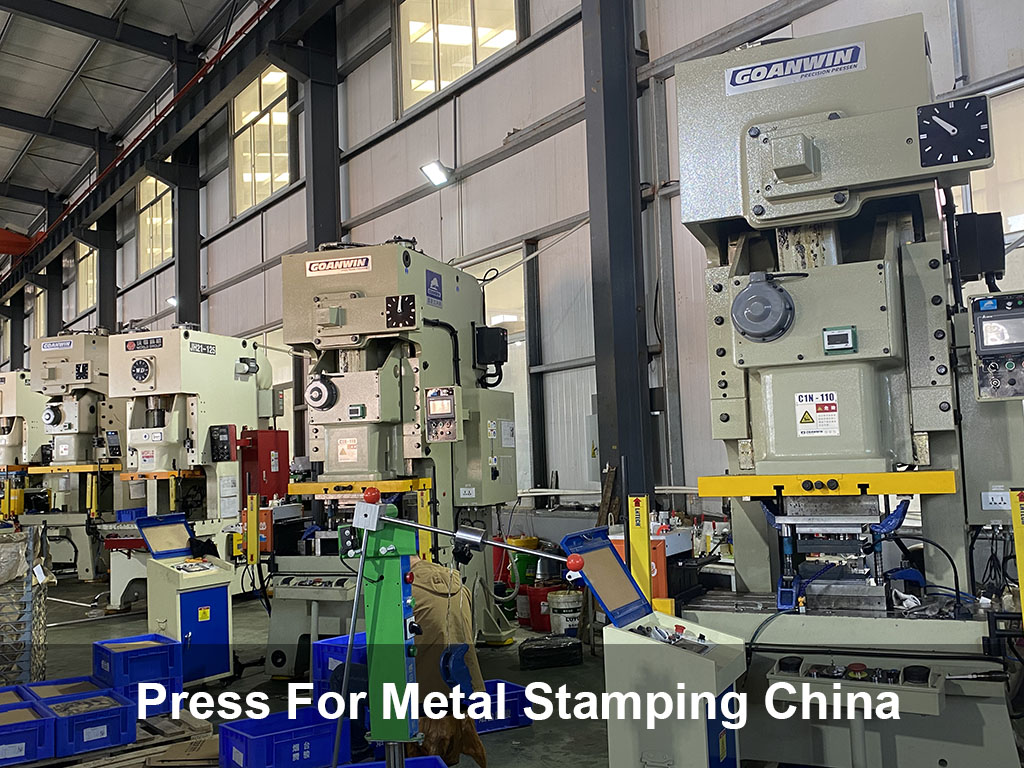

Stamping presses are key to ensuring production operations. We have 10 stamping presses, with the largest having a capacity of 300 tons. During high volume stamping, the speed of the tools is also a crucial factor. Our presses operate at speeds up to 400 strokes per minute, with an annual output exceeding 1 million pieces.

Quality Inspection for High Volume Stamping

Quality inspection of high volume stamped parts is also a challenge. Metaco typically develops quality inspection plans based on customer requirements.

We are honored to be TS16949 certified.