Deep Draw Stamping

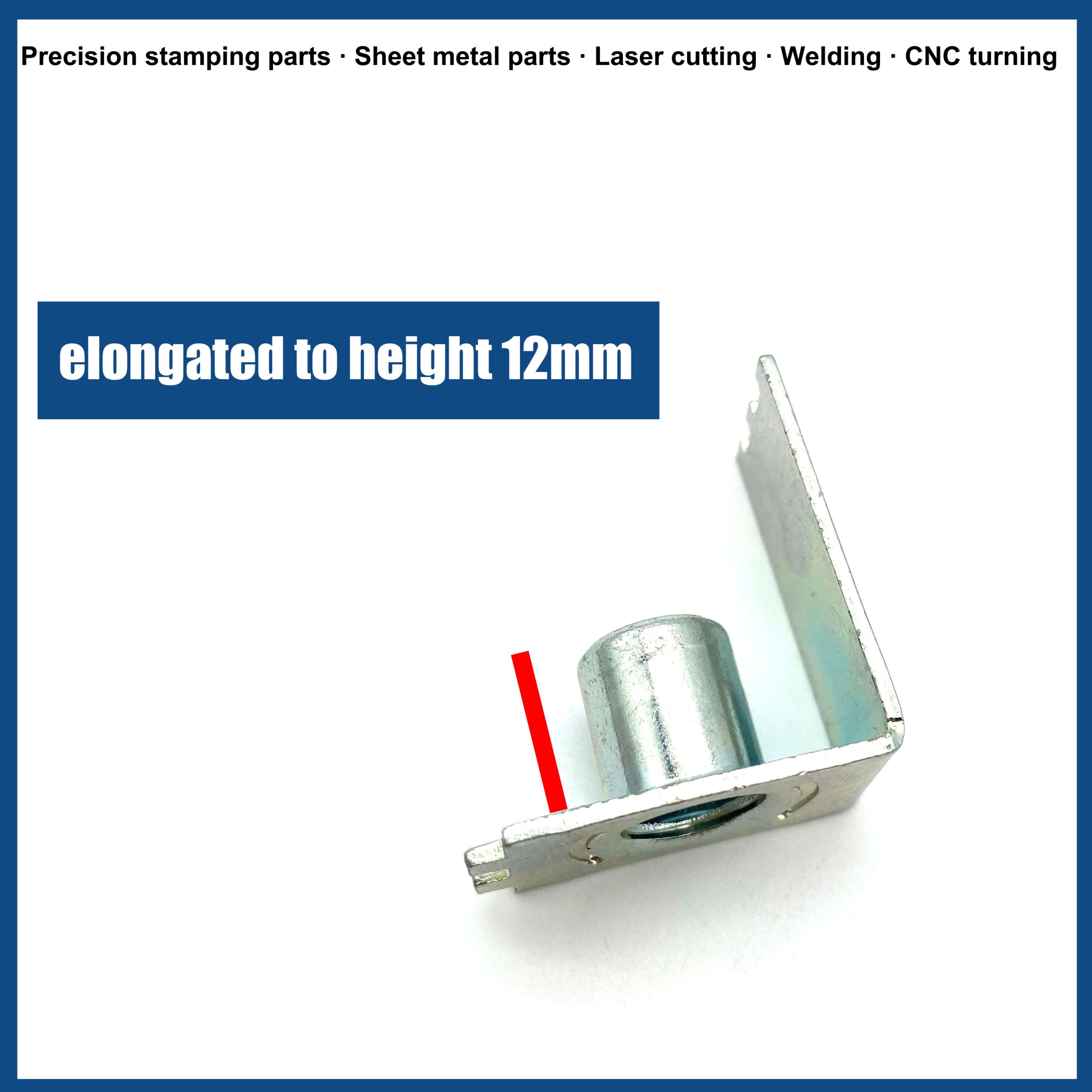

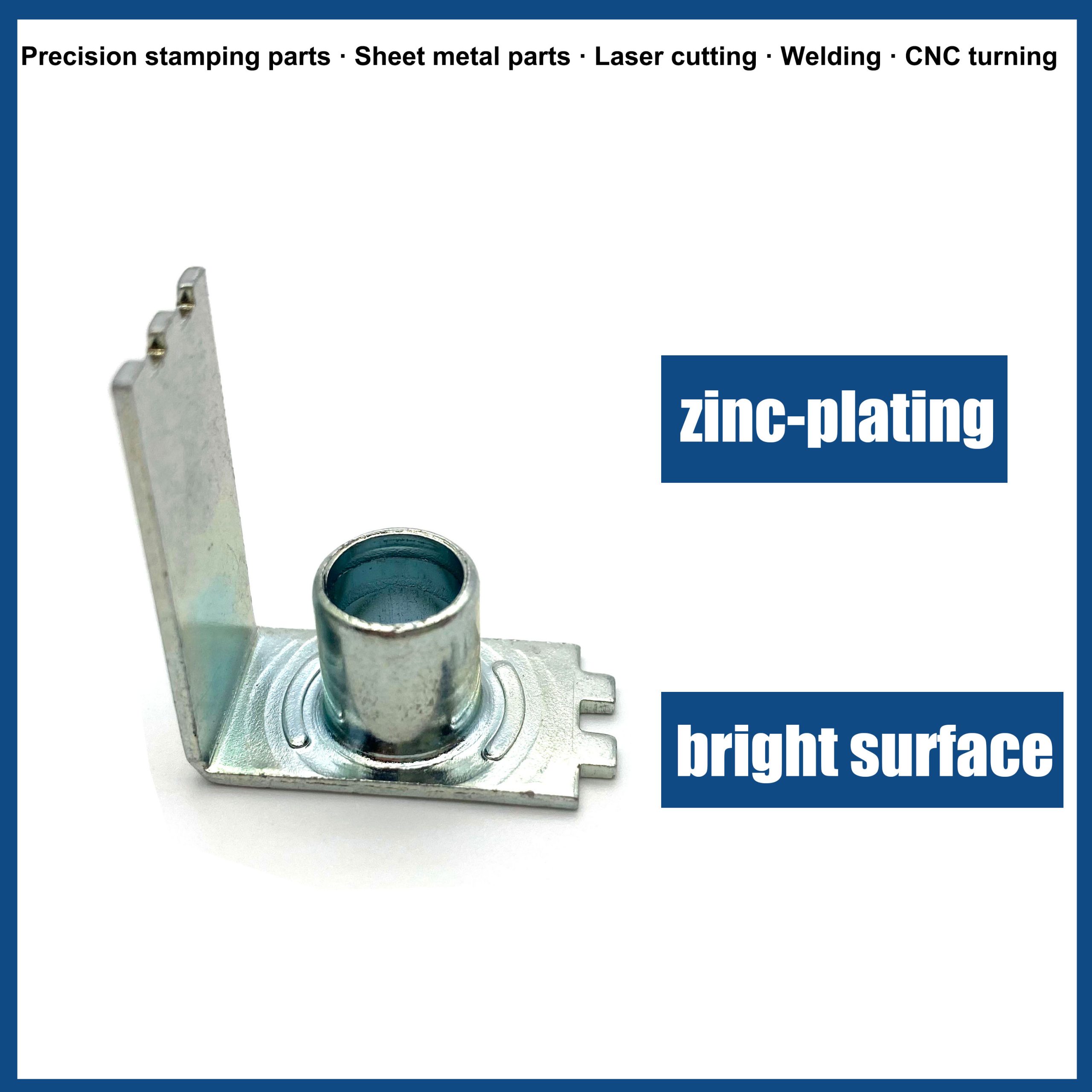

Deep draw stamping is a process that transforms flat metal sheets into complex, deep, and seamless components. Our begins with material selection, the metal sheet is then clamped and drawn into a die by a punch, shaping it into the desired form. Throughout the process, we maintain tight tolerances. This technique is ideal for high-volume production while maintaining quality.

Advantages of Deep Draw Stamping

Material Efficiency: This process minimizes waste, utilizing the majority of the metal sheet.

Strength and Durability: Products have superior structural integrity due to the work-hardening of the metal during the stamping process.

Complexity and Precision: Capable of creating complex shapes with high precision that other methods cannot achieve.

Cost-Effectiveness: Ideal for large-scale production, reducing overall manufacturing costs.

Versatility: Suitable for a wide range of metals, catering to diverse industry needs.

Comprehensive Deep Drawn Stamping Services

Our services extend beyond mere manufacturing. We offer: