Sheet metal Fabrication

Metaco has been committed to solving customers’ challenges in sheet metal part production—especially those involving complexity, small batches, and urgent timelines. We do not pursue high-volume, low-cost orders. Instead, we focus on the production of small to medium batches of high-complexity, high-assembly sheet metal parts, serving clients such as OEM manufacturers, new energy system integrators.

Sheet metal fabrication is not merely about cutting–bending–welding. Its true value lies in a deep, long-term understanding of materials, structures, and processes.

How We Make Sheet Metal Parts

We divide the entire manufacturing process into six stages:

Drawing Review → Process Analysis → Material Preparation → Production → Quality Control → Shipping.

Each stage is assigned to a dedicated workstation and personnel. Metaco is equipped with six functional areas: laser cutting, CNC bending, welding, grinding, assembly, and quality inspection, ensuring clear process flow and coordinated teamwork.

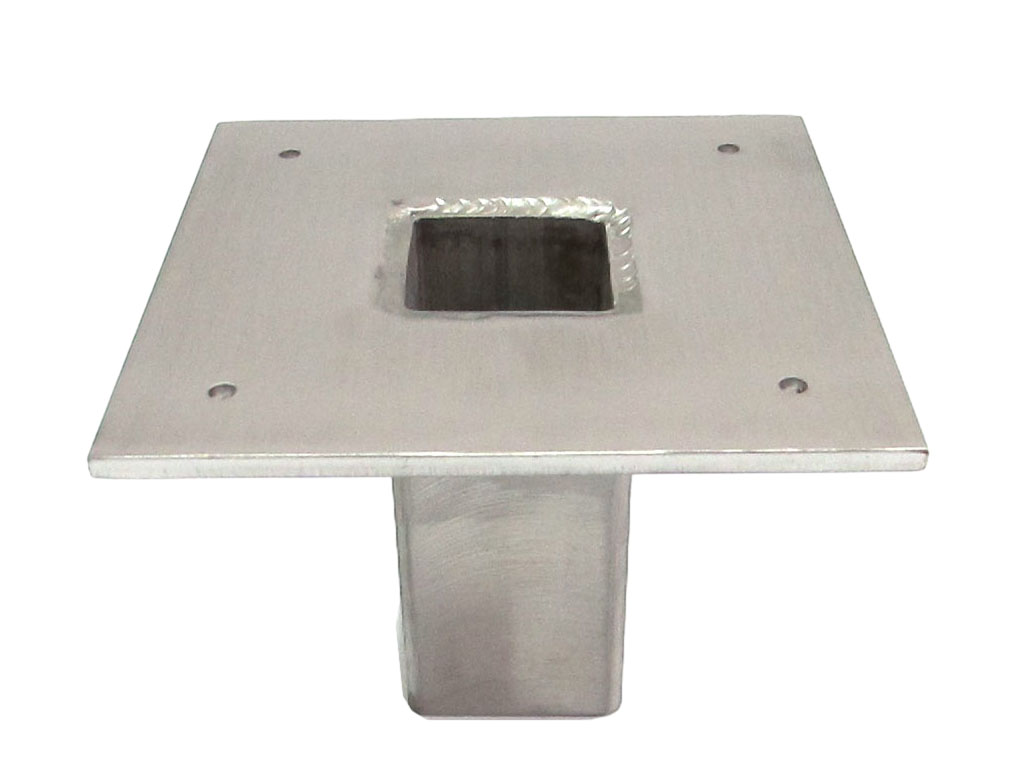

Cutting

We use a 6000W laser cutting machine to precisely cut stainless steel, aluminum alloy, and carbon steel sheets. The cuts are burr-free with minimal deformation, making them especially suitable for elongated structures and decorative components.

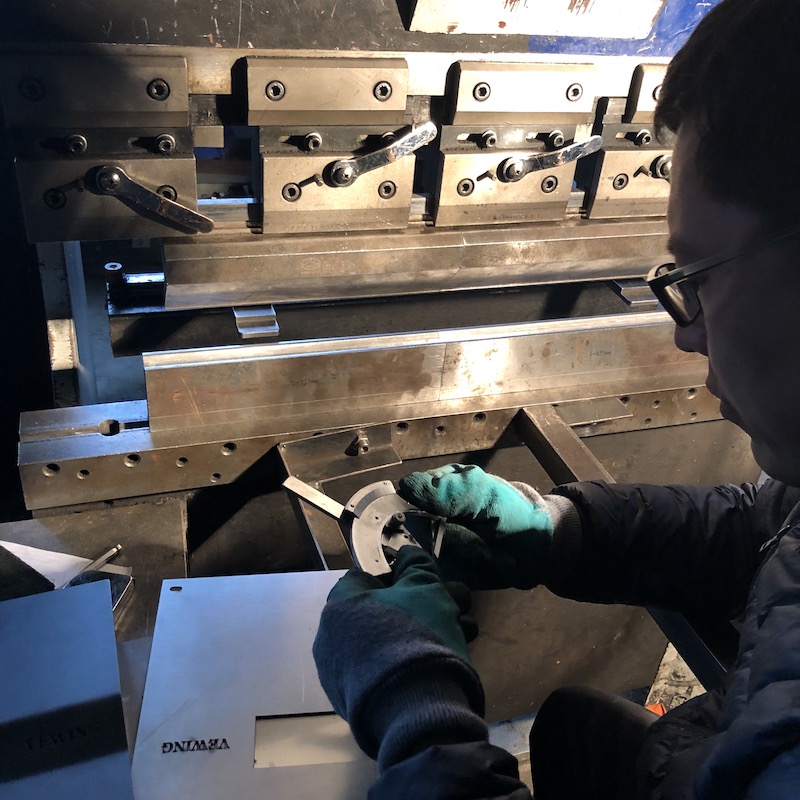

Bending

Our bending machines, paired with a standard mold library, can quickly produce complex, multi-angled, high-precision structures. We also maintain an internal bending simulation database to identify interference and deformation risks in advance.

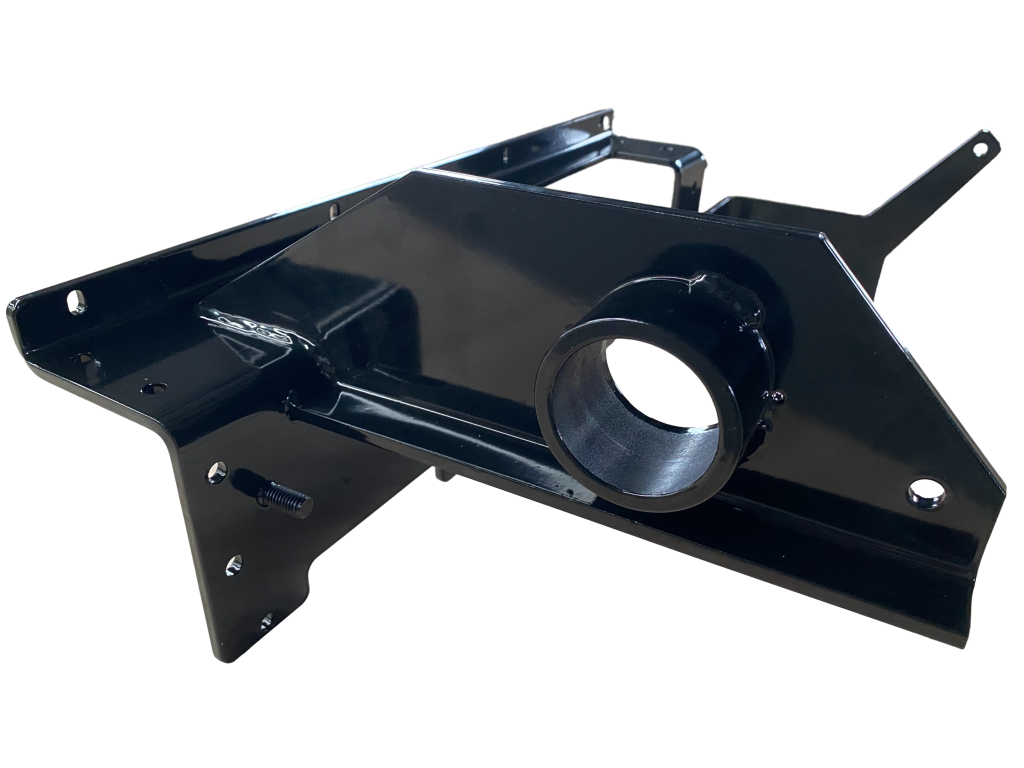

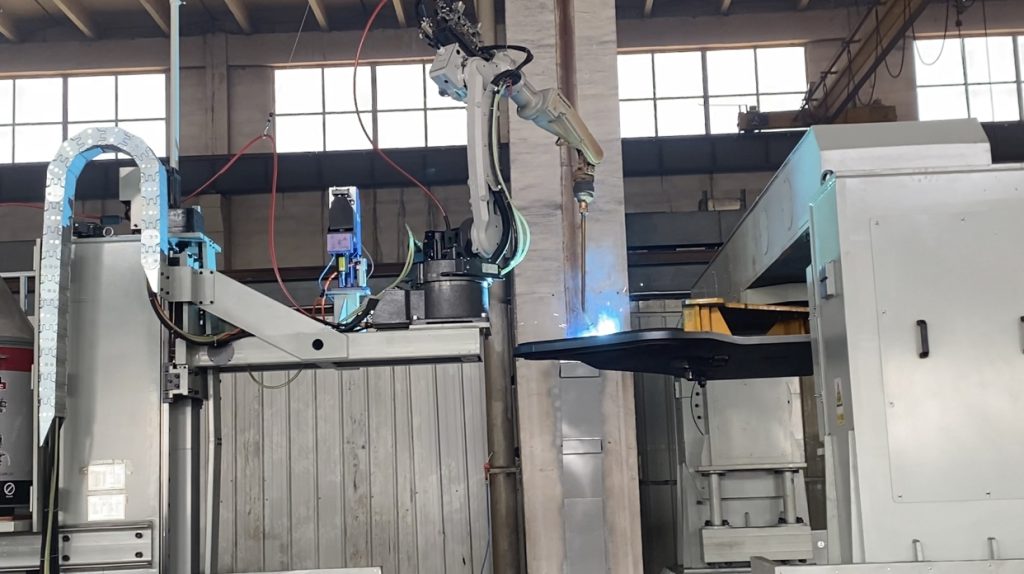

Welding & Assembly

Our welding team has extensive experience in large-scale sheet metal assemblies. They are skilled in thin sheet welding and deformation control techniques for stainless steel. Assembly Workstations are grouped by product type with standards.

Surface Treatment

Surface treatment is handled by two eco-compliant coating and plating partners, RoHS- and ISO-certified, who’ve partnered with us for over six years. For urgent or prototype orders, in-house brushing and deburring enable surface prep within 24 hours.

Why OEMs Choose to Work with Us Long-Term

No Need to Wait for Finalized Designs

Many clients tend to approach suppliers only after their drawings are fully finalized. But in reality, involving manufacturers during the structural design stage can help avoid issues like welding deformation, machining dead zones, and assembly conflicts early on.

Metaco encourages early involvement. We welcome collaboration even in the stage of rough sketches or preliminary concepts—this is often how we help our clients shorten development cycles and reduce costs from the beginning.