Compound Die Stamping Service

At Metaco, we offer expert compound die stamping for medium to low volume parts. Compound dies are more cost-effective than progressive dies and can consistently hold tight tolerances, ideal for flat blanks, drawn cups, and rings. This method eliminates the need for multiple dies, saving time and reducing tooling costs.

Our facility features 3 300ton presses, which, when combined, function as a powerful 900ton compound line. With the ability to run multiple dies in one operation, our line ensures increased efficiency.

Capabilities for Compound Die Stamping at Metaco

| Aspect | Details |

|---|---|

| Press Capacity | Presses ranging from 180 to 300 tons |

| Materials | Steel, aluminum, titanium, brass, Hastelloy, etc. |

| Material Thickness Range | From 0.010″ to 0.325″ |

| Certification | TS16949:2016 certified |

Benefits of Compound Die Stamping

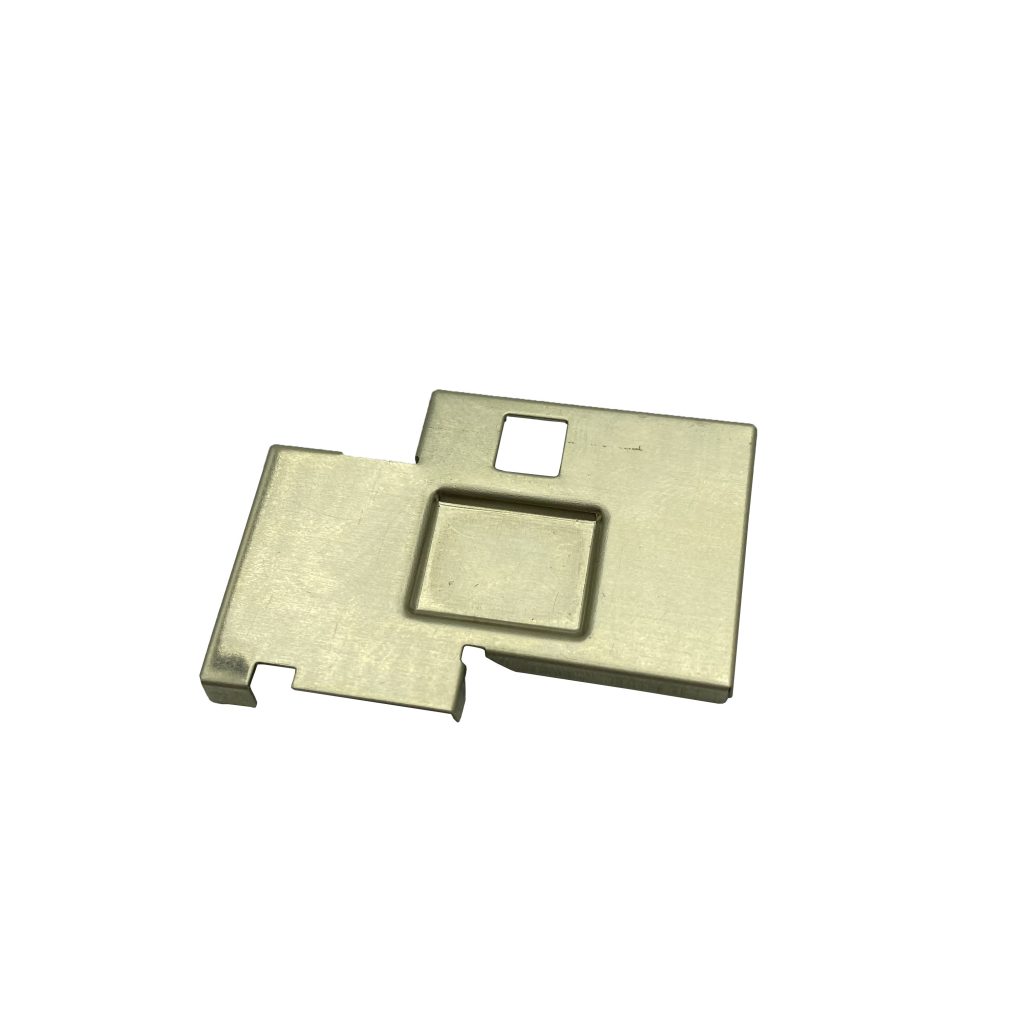

Compound Die Stampings