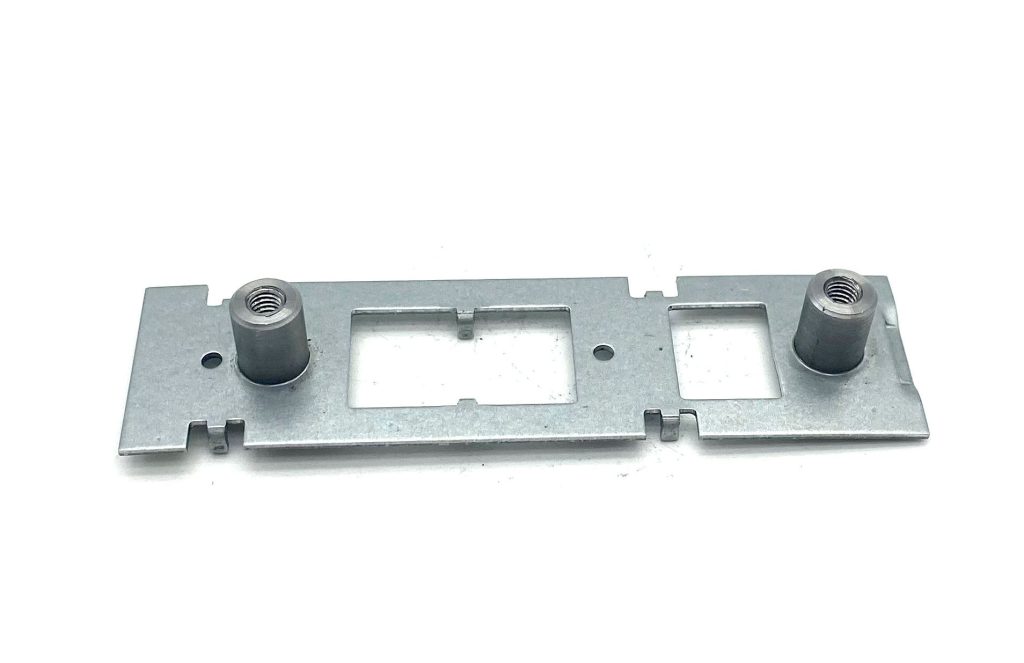

Aluminum Stamping

At Metaco, we specialize in aluminum stamping, a process that transforms aluminum sheets into various shapes and designs with precision. Aluminum, known for its strength, light weight, and corrosion resistance, is an ideal material for numerous applications across industries.

Whether it’s creating complex parts or maintaining tight tolerances, our stamping equipment and skilled operators are up to the task. This process includes a range of techniques like blanking, punching, bending, embossing, flanging, drawing, curling, and coining, offering versatility in manufacturing.

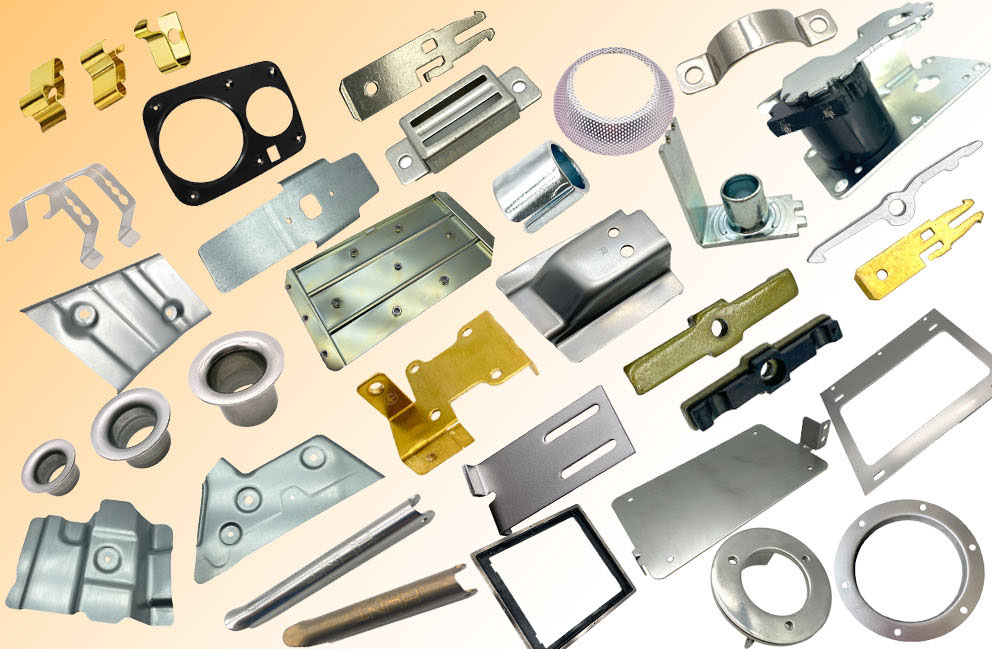

Contract Aluminum Stamping Parts

Customization is key in our aluminum stamping services. Our team accommodating a variety of custom requirements from the initial concept through to production. We use CAD software and 3D modeling to ensure the design is optimized for stamping. Whether you need a specific thickness, unique finish, or a particular aluminum grade, we are equipped to deliver.

Prototyping of aluminum stampings

We offer rapid prototyping services to quickly turn designs into tangible products, ensuring a fast turnaround without compromising on quality.

We understand that each industry has its unique demands. That’s why our contract aluminum stampings are found in a wide array of applications – from intricate components in electronic devices to robust parts in automotive manufacturing. Our flexible manufacturing process allows us to produce both small and large-scale orders, catering to diverse client needs.