What thickness does the plating make?

Electroplating is the process of precipitating a layer of metal on the base part. Is there a limit of the thickness for the electroplating?

Due to the principle of electroplating, the layer of plating is porous structure. When the thickness grows, the structure becomes more porous, which makes the plating less compact and less solid. So there are limits for different plating.

Table of Contents

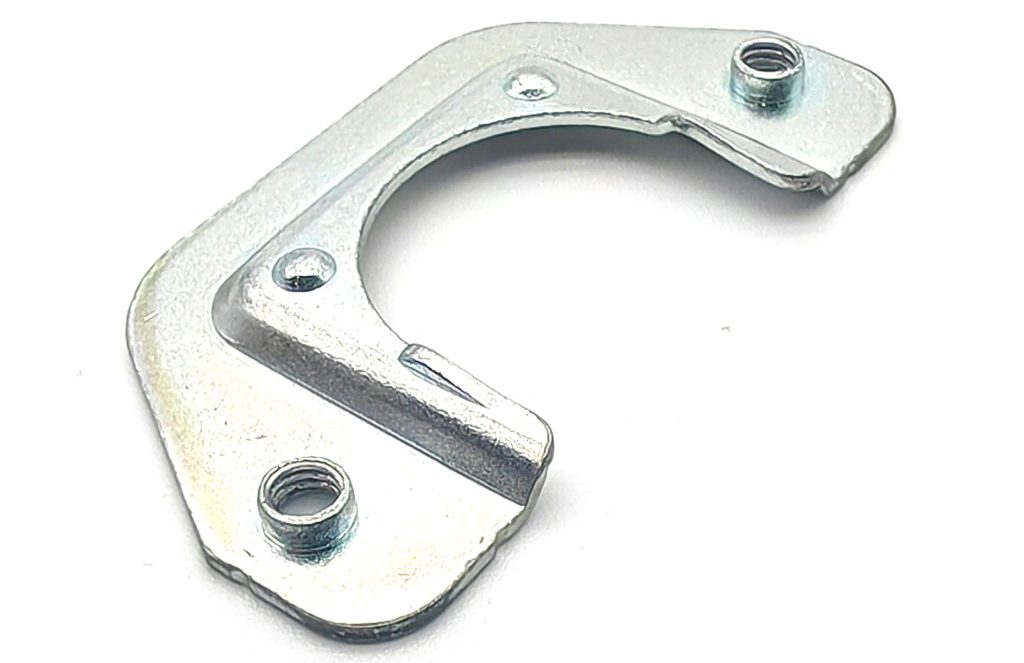

Zinc Plating

Zinc is the most popular plating, due to work piece size, bigger work piece requires thicker plating, generally from 55 microns to 85 microns.

For hard chrome plating, the maximum thickness is normally 10~25 microns, some extreme applications like corrosion resistance may require 50 microns.

nickel plating

For nickel plating, most of the home appliances and hardware fittings require 0.5 to 5 microns while auto parts may require 5 to 25 microns.

Gold plating

Gold plating has the best electric conductivity. Normal thickness for gold plating is 0.1 to 0.3 microns, for high temperature or electric connector, the thickness is 0.5 to 5 microns.