Understanding Stamping Die Components

In the world of metalworking, precision and efficiency are paramount. Stamping dies play a pivotal role in achieving these goals, thanks to their intricate components. These tools designed to manipulate metal sheets into specific shapes and sizes with accuracy. Let’s explore the essential components of stamping dies, their types, and functions.

Table of Contents

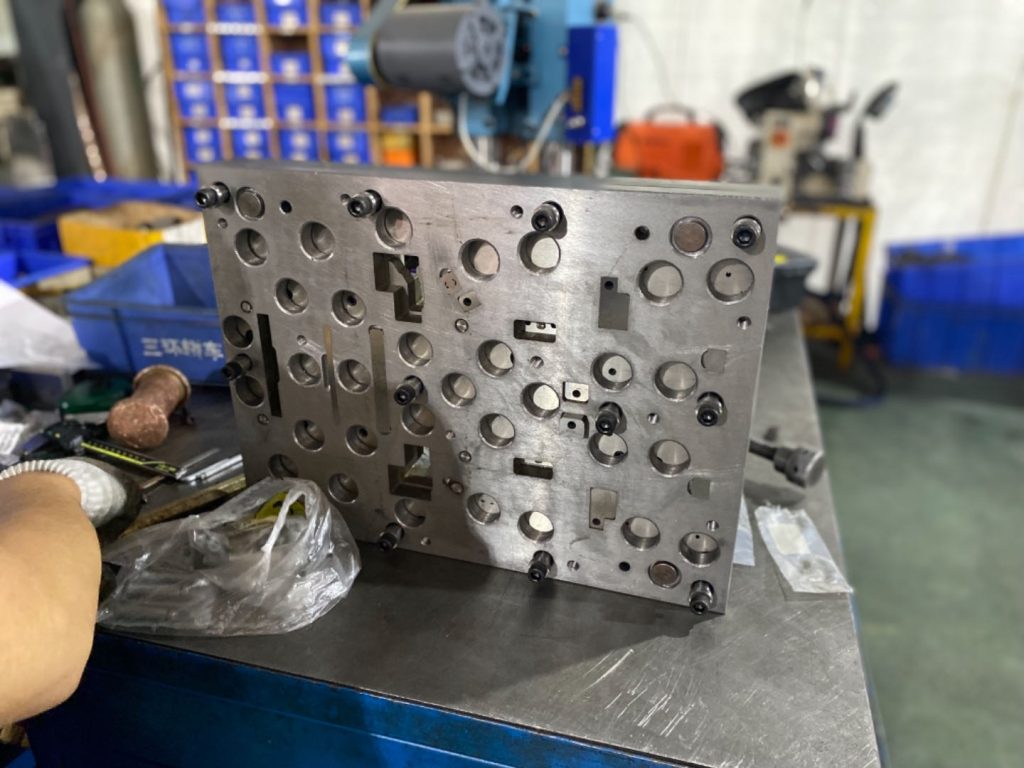

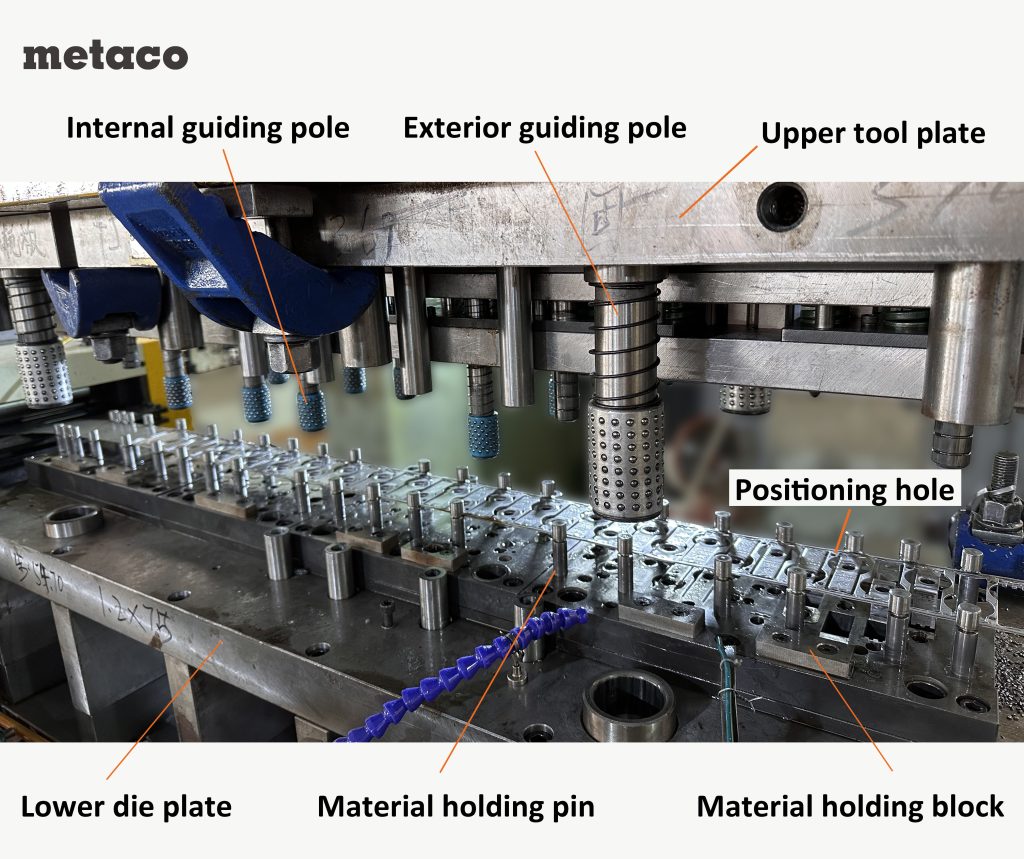

The Structure of Stamping Dies

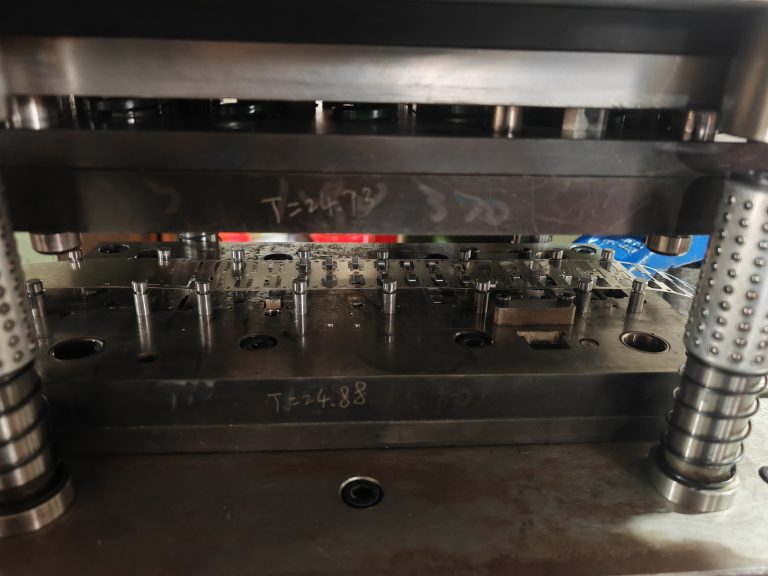

Stamping dies are typically divided into two main sections: the stationary section (lower die) and the movable section (upper die). The lower die is securely fastened to the punch press’s worktable using clamps and screws, while the upper die attaches to the punch press’s slider, moving up and down to perform the stamping operation.

Key Components Of Stamping Die and Their Roles

Working Components

The heart of the stamping process lies in the working components, such as punch inserts, die inserts, and punch matrices. These parts directly interact with the metal sheet, deforming and separating it to form the desired workpiece.

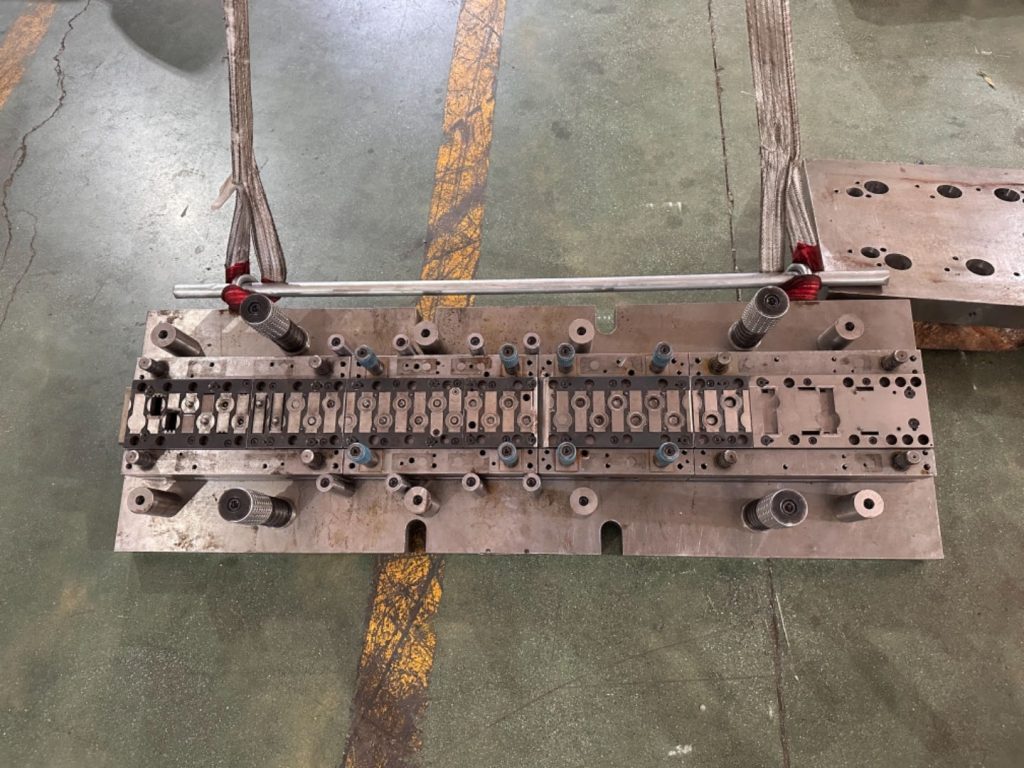

Pilot Components

Accuracy in feeding the raw material sheet is crucial. Pilot components like pilot pins, locating pins, and guide pins ensure that the material is precisely positioned within the die for accurate stamping.

Material Press, Stripping, and Lifting Components

After each stamping cycle, it’s vital to remove the workpiece and any scrap efficiently. Components such as stripper plates and lifting pins facilitate this process, ensuring seamless production flow.

Guide Components

To maintain the quality of the stamped parts, guide components ensure the upper and lower dies align correctly during their movement. This precision alignment prevents uneven wear and contributes to the longevity of the die.

Install and Fasten Components

The structural integrity of the stamping die is maintained by various fastening components. These ensure that all parts of the die are correctly aligned and securely attached, allowing for accurate installation on the punch press.

While the five types of components mentioned are fundamental to all stamping dies, additional features may be integrated for high-volume productions. Advanced dies might include automatic feeding and ejection devices to further enhance production efficiency and part quality.

Metaco specializes in metal stamping, offering a comprehensive suite of services that includes in-house tooling, design, production, assembly, and maintenance. Our integrated approach ensures high-quality results tailored to your needs. For a detailed quote and to learn more about how we can support your project, please Contact Us!