Understanding CNC Machining in OEM Metal Fabrication

In OEM metal fabrication, CNC machining is a core process used to produce components with consistent dimensions, defined tolerances, and reliable repeatability. For many OEM projects—especially those involving low to medium production volumes, design complexity, or varied materials—CNC machining provides a practical and scalable manufacturing solution.

Table of Contents

What CNC Machining Does in the OEM Context

CNC, or Computer Numerical Control, refers to the use of programmed instructions to guide machine tools. The process typically involves milling, turning, drilling, and tapping operations, applied to metal workpieces based on design files. In OEM manufacturing, this method is used to produce both prototypes and final parts according to client specifications.

Unlike processes such as stamping or casting, CNC machining removes material directly from solid blocks (billets) and does not require dedicated tooling. This makes it suitable for small production runs or components that may undergo design revisions over time.

Tolerance and Dimensional Control

OEM components often require tight dimensional accuracy for proper assembly and function. CNC machines, when properly maintained and calibrated, can achieve tolerances in the ±0.01 mm range or better, depending on material and geometry. This level of control helps reduce downstream issues such as part misalignment, poor fit, or mechanical failure in assembled systems.

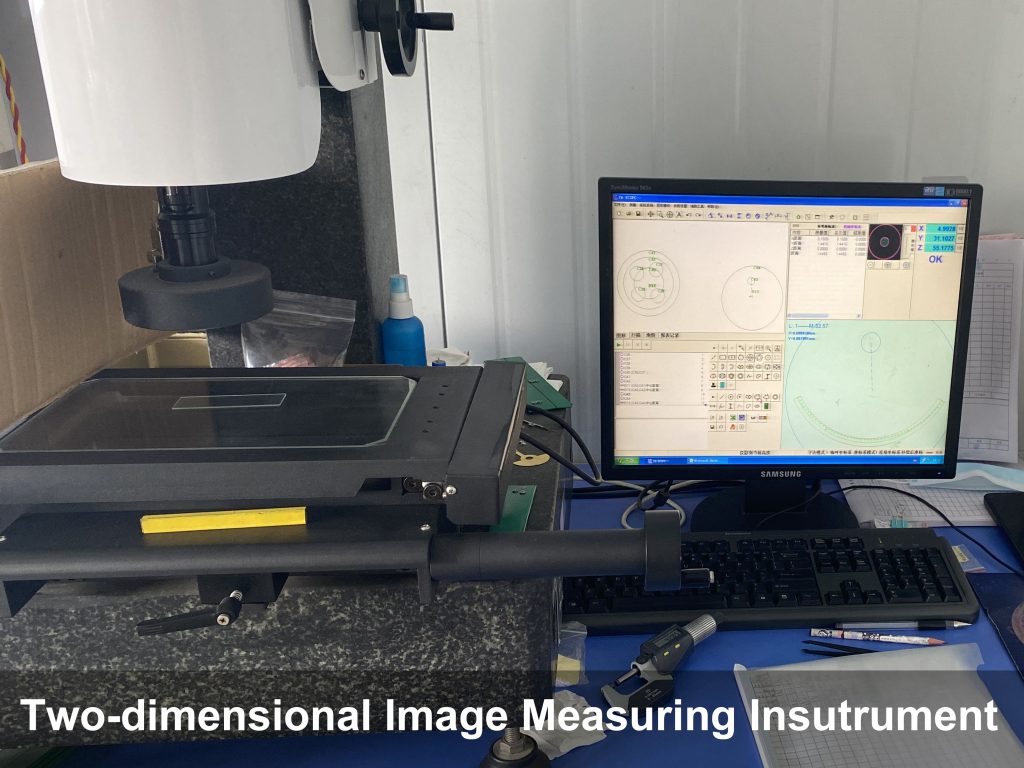

Dimensional data can also be verified using coordinate measuring machines (CMMs), calipers, or profile projectors to meet client inspection protocols.

Material Compatibility

This flexibility allows clients to select materials based on cost, weight, corrosion resistance, and mechanical performance—without changing the basic fabrication method.

When CNC Machining Is Appropriate

CNC is a suitable method when:

For very high volumes of simple parts, processes such as stamping or die casting may offer lower per-unit cost. However, CNC machining remains common for pre-series, replacement parts, and assemblies requiring precision fitting.