Metal Stamping Die Design and Manufacturing Process

Stamping dies play a key role in the stamping process, affecting the quality and efficiency of parts production. Designing and manufacturing a suitable die involves several steps. Below is an overview of the stamping die design and manufacturing process.

Table of Contents

1. Preliminary Preparation for Die Design

Before designing the die, it is essential to understand the part requirements, shape, and production process. The main tasks during this phase are confirming the part’s function, dimensions, and determining if it can be produced using stamping. In addition, selecting the appropriate material and determining the production process are also crucial.

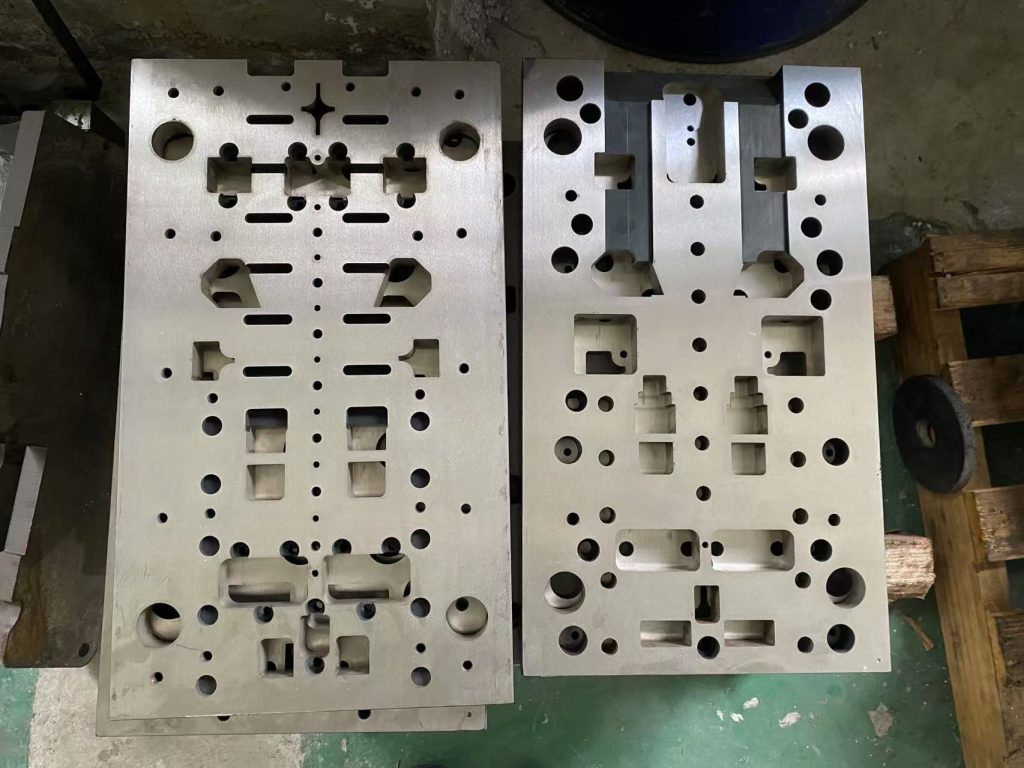

2. Key Elements of Die Design

The main goal of die design is to ensure the die can perform the stamping process efficiently and accurately. During the design phase, structural design is critical to ensure all components fit together properly. The process flow must also be clear to ensure smooth operations at each step. Material selection should meet production requirements, and the die’s precision must meet the required standards for the parts.

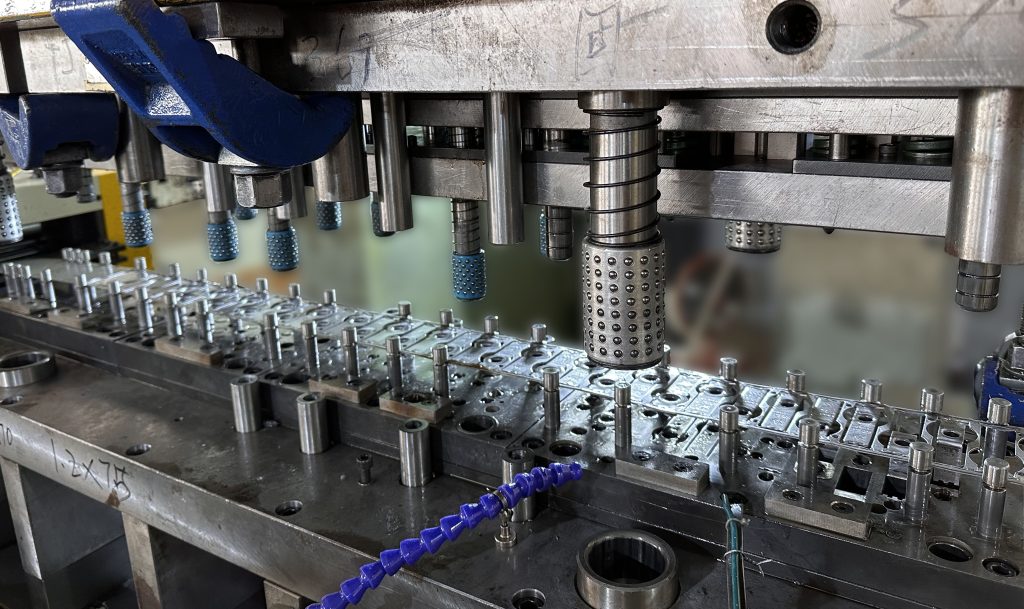

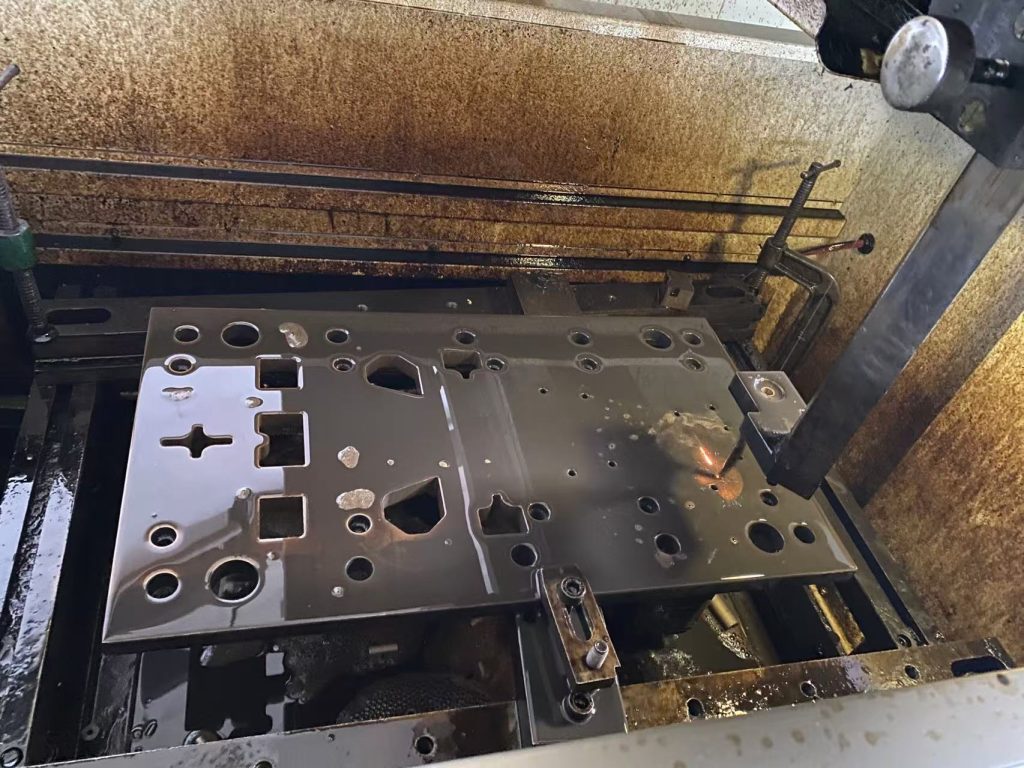

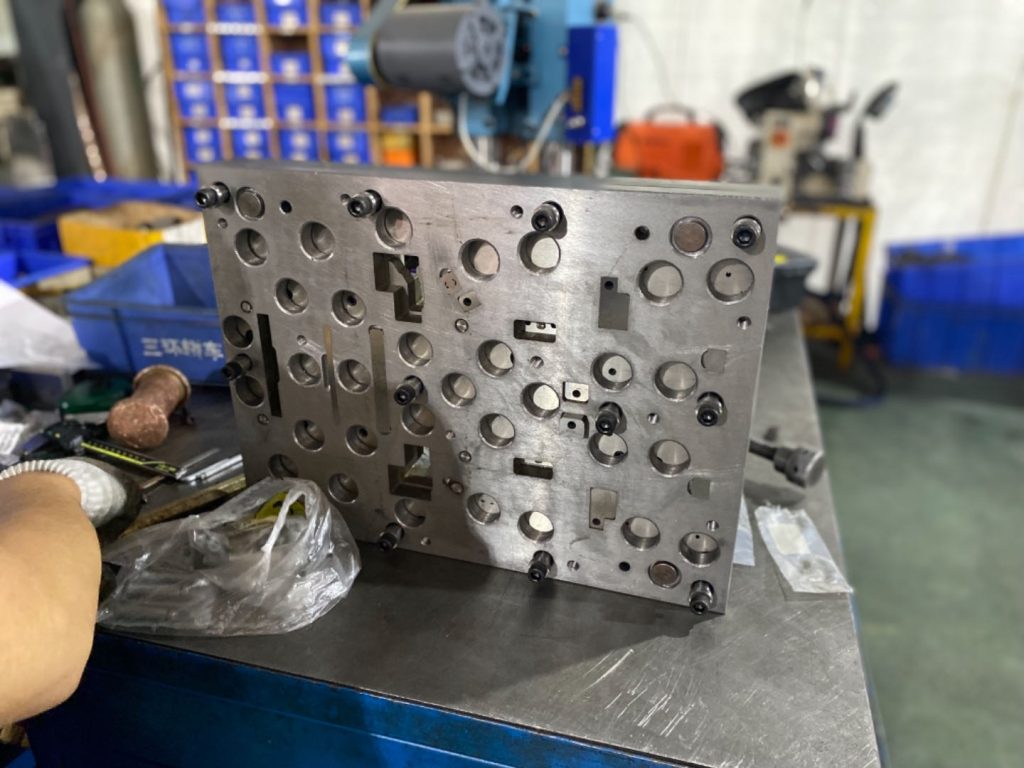

3. Die Manufacturing Process

The die manufacturing process consists of several key steps. First, the material is prepared and cut according to the design blueprint. Then, rough and fine machining is performed to ensure accurate dimensions. After that, the die components are assembled and adjusted to ensure proper fit. Finally, a trial run is conducted to test the die’s ability to produce quality parts, and adjustments are made based on the results.

4. Die Maintenance and Care

Over time, dies will experience wear and tear, so regular maintenance is necessary. Key maintenance tasks include: checking the wear of the die and performing repairs if needed, lubricating moving parts to reduce friction, and periodically calibrating the die to maintain accuracy over time.

5. Extending Die Lifespan

The lifespan of a die impacts both production efficiency and cost. To extend a die’s lifespan, strategies include selecting durable materials, optimizing the stamping process, and conducting regular maintenance. These measures help reduce wear, minimize downtime, and improve overall production efficiency.