How to Quickly Evaluate the Process Capability of a Stamping Supplier

For stamping parts with complex structures or demanding tolerances, a supplier’s actual process capability directly impacts delivery risk. The following five…

For stamping parts with complex structures or demanding tolerances, a supplier’s actual process capability directly impacts delivery risk. The following five…

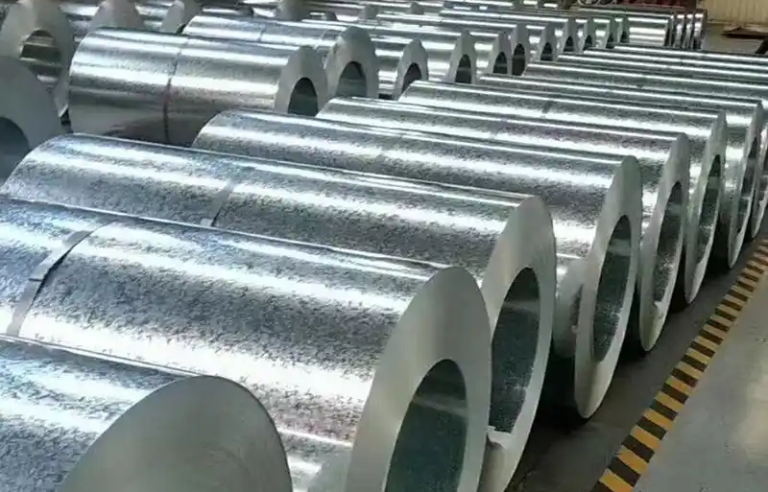

High-strength steel exhibits significantly different behavior compared to conventional low-strength steel during stamping. The associated forming difficulties have become key concerns…

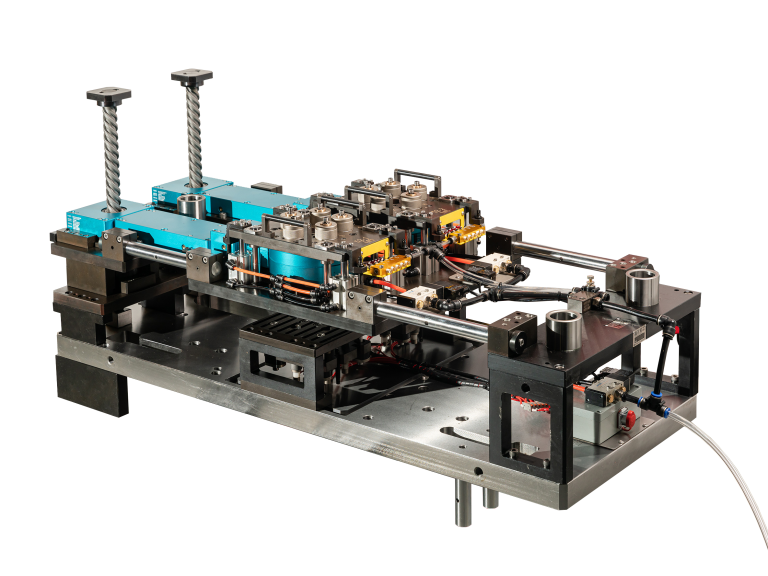

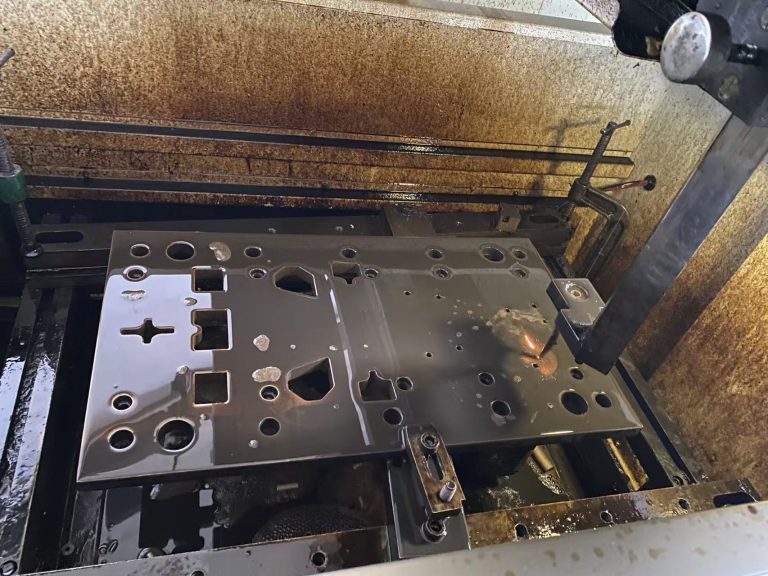

Stamping dies are critical tools in high-volume metal forming. Their design directly affects part accuracy, production efficiency, and tool durability. A…

Rapid Prototyping (RP) is a process that uses rapid forming technology to quickly produce product prototypes, aimed at accelerating product design…

1. Cracking and Fractures Cause: This defect occurs when the material is subjected to excessive stress during the forming process, often…

Metal stamping is suitable for contour forming and preliminary structural processing of high-volume parts. It features fast forming speed and high…

Finishing refer to the processes applied to the stamped metal parts after they have been formed but before they are assembled…

Understanding OEM Metal Stamping OEM (Original Equipment Manufacturing) metal stamping refers to contract-based production of stamped metal components based on customer-supplied…

Quality control (QC) is a critical aspect of the metal stamping process. In this post, we’ll dive into the various techniques…

When it comes to stamping out thousands (or even millions) of identical metal parts every month, small tweaks in your setup…