Precision Manufacturing for Intricate Stamping Parts

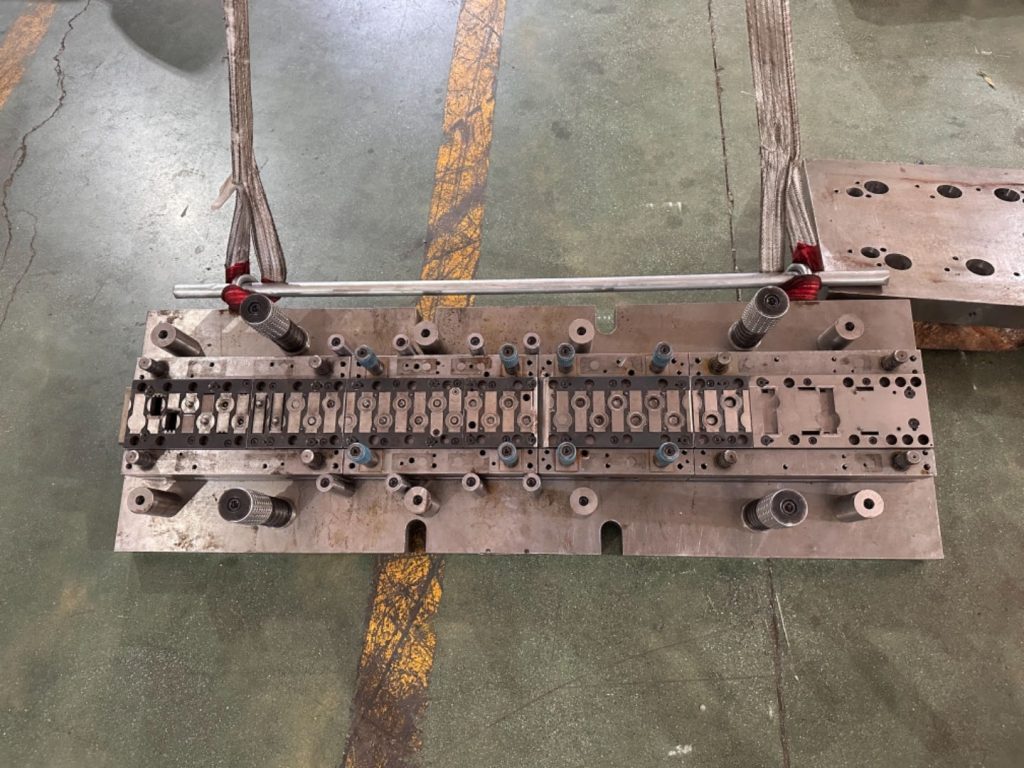

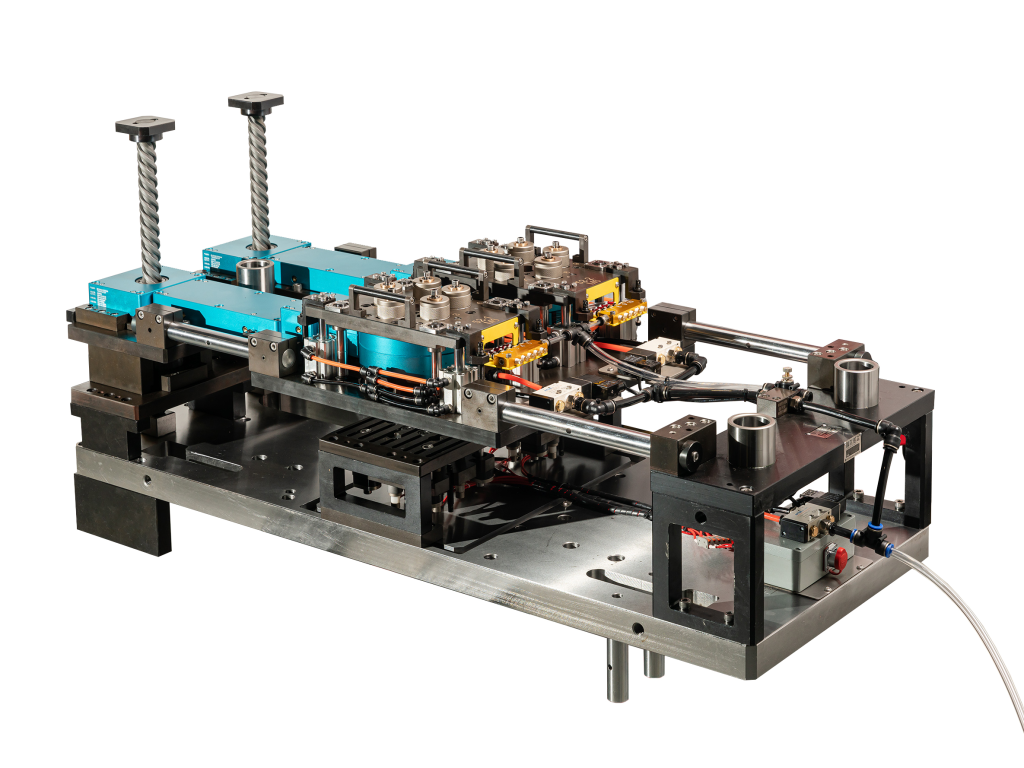

Intricate stamping is a process used to manufacture irregularly shaped and complexly structured metal parts. It mainly uses multi-station progressive dies or composite dies to make the material present different geometrical shapes through forming methods such as punching, drawing, bending, etc. in order to meet the manufacturing needs of complex parts.

Table of Contents

Main Characteristics of Intricate Stamping

Common Intricate Stamping Process Combinations

Common Intricate Stamping Process Combinations

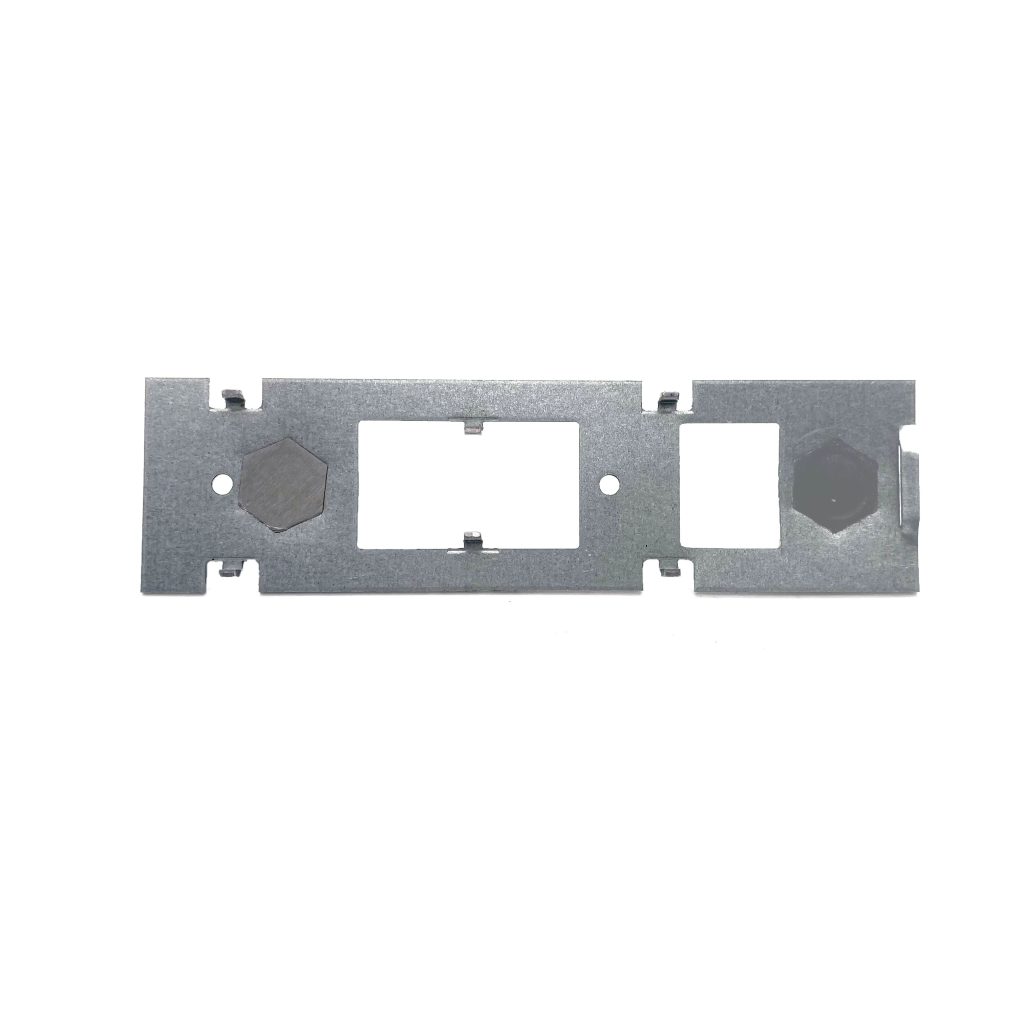

Irregular Stamped Parts are characterized by complex structures and a high degree of customization. In their design and production processes, they not only require precision stamping manufacturing but also often involve the integration of various supplementary processes:

Riveting

This includes Self-Piercing Riveting and Press-fit Nuts, used to fasten stamped parts to other metal or plastic components.

Welding

This includes Spot Welding and Laser Welding, suitable for connecting parts that require high structural strength and sealing capabilities.

In-die Tapping

This technology directly forms threaded holes during the stamping process, eliminating the need for subsequent machining steps. It significantly improves production efficiency and consistency, particularly for medium to large-volume production.

Cold Heading

A type of plastic forming process often used in conjunction with stamping, especially for producing fasteners with complex head structures (e.g., cross-slot, hexagonal heads).