Deep Drawing vs. Shallow Drawing in Metal Stamping

In metal stamping, deep drawing and shallow drawing are two commonly used forming processes. Understanding the differences between them will help you make an informed decision about which manufacturing process is best for your project.

Table of Contents

What Is Metal Drawing

Metal drawing is a process where a metal sheet is pulled into a die to form specific shapes. In this process, the metal sheet is gradually stretched into the desired form by the punch. Depending on the depth of the part, the complexity of the geometry, and the characteristics of the material, either deep drawing or shallow drawing can be used.

By understanding the differences between these two processes, you can make a more targeted production decision.

Deep Drawing Process Features

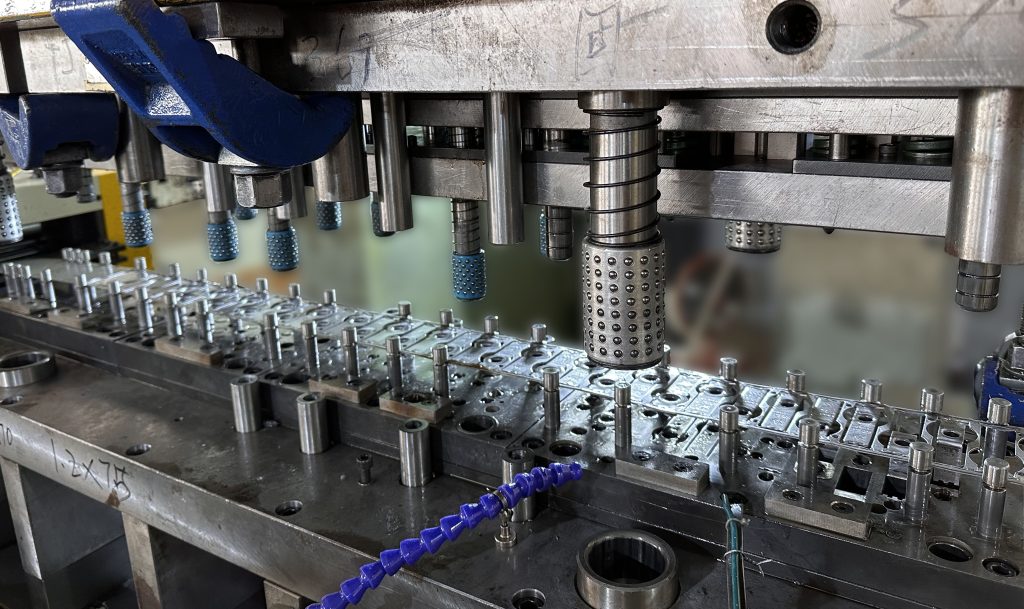

Deep drawing is used to create parts with a depth greater than their diameter. The process involves multiple stages of stretching the metal sheet until the desired shape is achieved. Deep drawing requires precise control of the die and punch, and lubrication is often used to reduce friction.

Advantages of Deep Drawing

Challenges of Deep Drawing

Shallow Drawing Process Features

In contrast to deep drawing, shallow drawing is used for parts with a smaller depth than their diameter. The process is usually simpler and completed in a single stage, making it faster and less expensive.

Advantages of Shallow Drawing

Challenges of Shallow Drawing

Contact Us for Custom Solutions

At Metaco, we specialize in providing high-precision metal stamping services. Whether you need prototyping or large-scale production, we can offer customized solutions to help you optimize your production process and reduce costs.