Understanding Quality Assurance in Metal Stamping

Quality Defined: Quality in metal stamping aligns with the IATF 16949:2016 definition, emphasizing the fulfillment of requirements through the inherent characteristics of the product. Our goal is to ensure each part not only meets but exceeds design specifications and operational expectations.

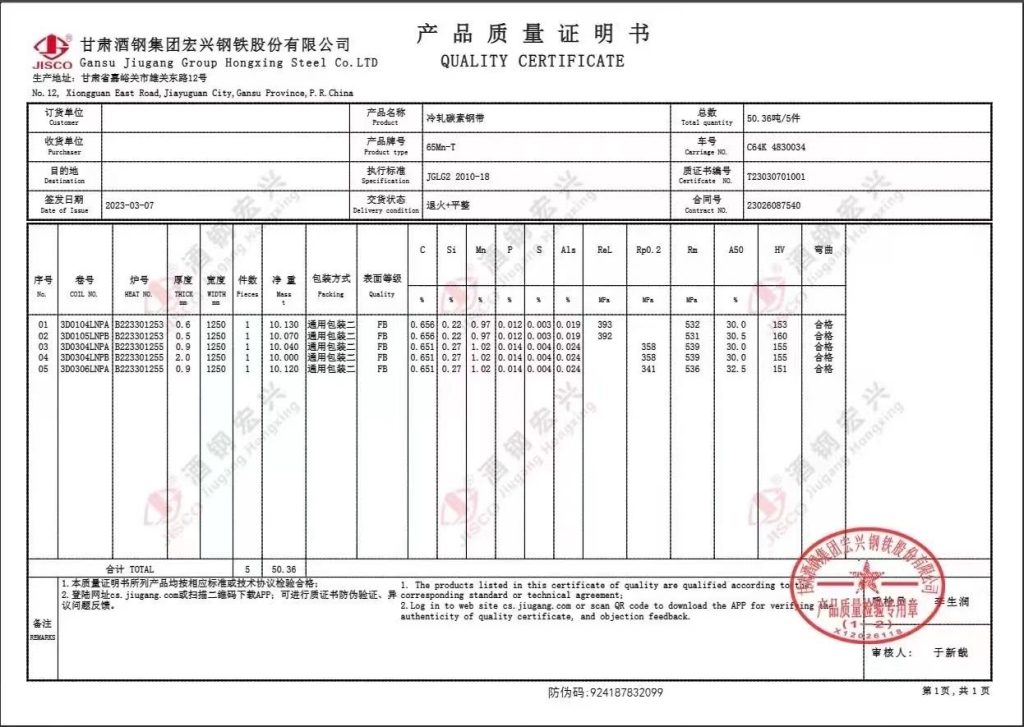

Pre-fabrication Quality Checks: The QA journey begins with a thorough inspection of raw materials, ensuring their suitability for the intended parts. Techniques such as Failure Mode and Effects Analysis (FMEA) and Advanced Product Quality Planning (APQP) are employed to identify potential process failures and establish manufacturing processes that align with customer expectations.

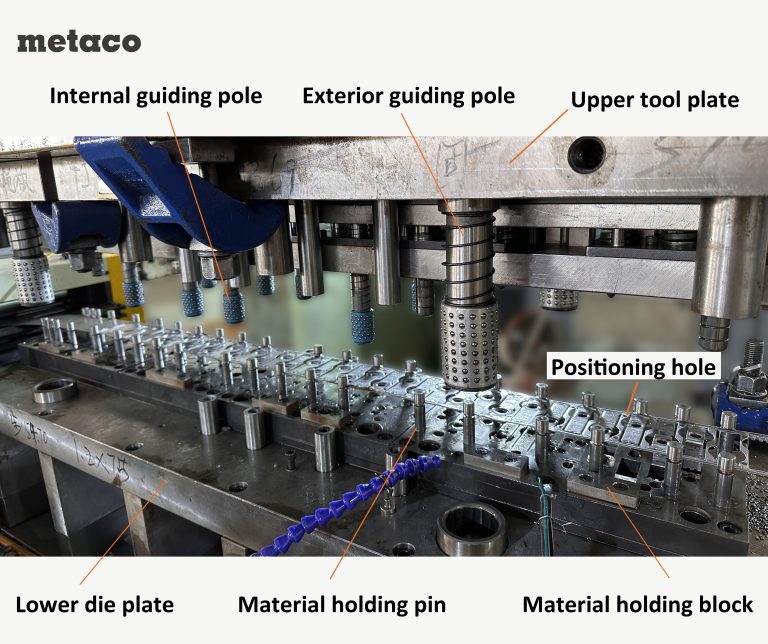

During Fabrication Monitoring: Real-time monitoring and documentation of the fabrication process are crucial. This phase ensures adherence to various quality standards such as the Pressure Equipment Directive (PED), Restriction of Hazardous Substances (RoHS), and IATF 16949:2016, alongside internal quality policies. Our commitment extends to compliance with specific regulations.

Post-fabrication Quality Assurance: Our approach includes rigorous inspections at multiple stages of manufacturing, culminating in 3D scanning techniques for final inspection, ensuring the highest level of precision and quality.