Metal CNC Service for Custom Parts

Metal CNC machining is a method that uses computer numerical control to guide the machining process, suitable for custom production of various metal parts. We offer a full-process machining service, from design to finished product, ensuring that each part strictly meets customer requirements.

Table of Contents

Materials and Selection

We offer machining services for various metal materials, including aluminum, stainless steel, titanium alloys, and copper. Each material has different cutting characteristics, and we select the appropriate material based on the customer’s design and part requirements. We adjust processing parameters (such as cutting speed, feed rate, cutting depth, etc.) to optimize the machining results.

CNC Machining Technology

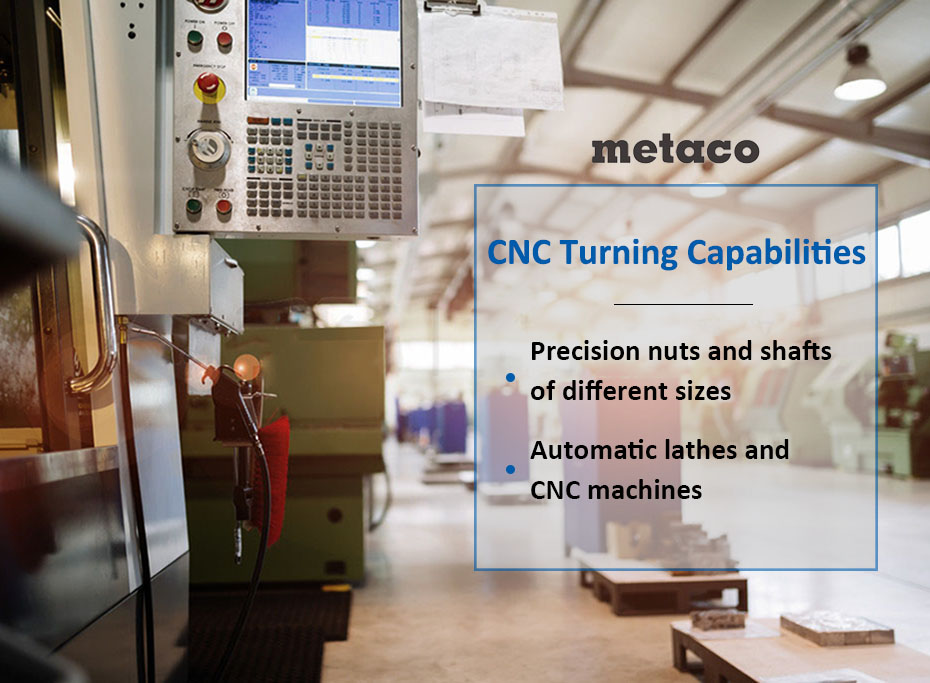

CNC machining uses computer-controlled machine tools to automatically process parts based on the customer’s CAD files. The machine tools execute cutting, milling, drilling, and other operations according to the pre-programmed procedure, ensuring high precision and consistency of parts. Compared to traditional manual machining, CNC machining reduces human error and improves consistency in mass production.

Precision and Tolerance

We can meet various tolerance requirements, with common precision ranges including ±0.05mm, ±0.1mm, and others. Through high-precision CNC equipment and real-time dimensional checks, we ensure that the dimensions and tolerances of parts fully comply with customer design specifications. For complex parts, we also use coordinate measuring machines (CMM) and other tools for precise measurement and verification, ensuring machining accuracy.

Machining Process

1. Design Confirmation: The customer provides CAD or CAM files, and we conduct a preliminary analysis to ensure the feasibility of the process.

2. Material Cutting and Preparation: Suitable raw materials are prepared based on the selected metal material.

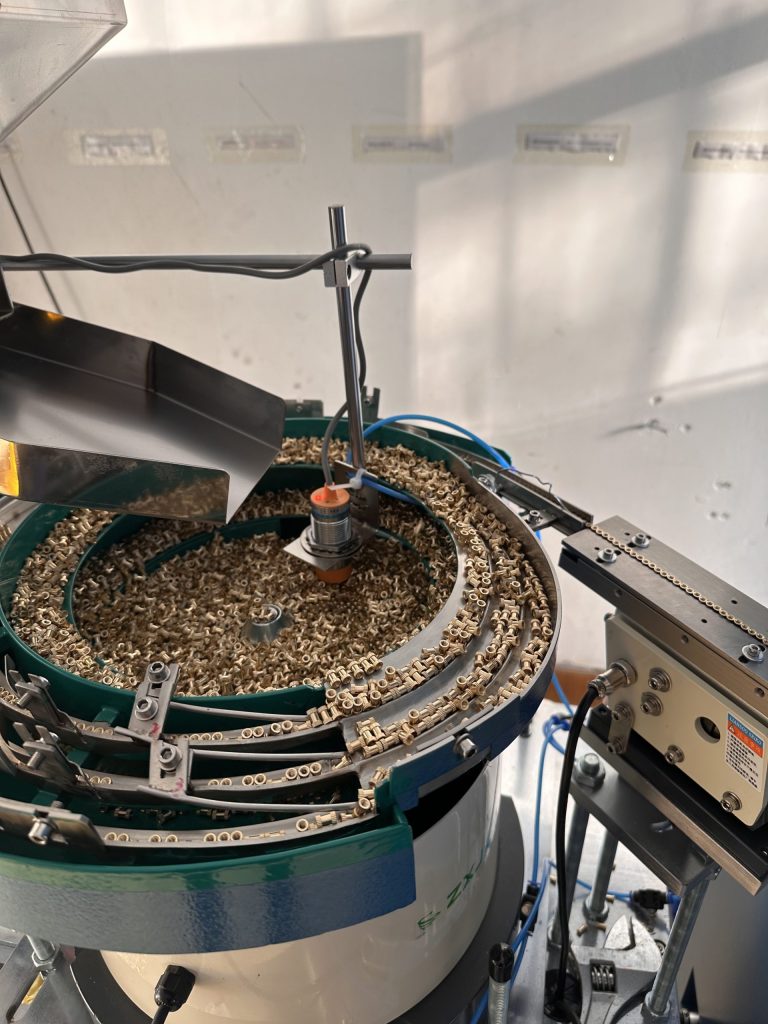

3. CNC Machining: The parts are processed using milling machines, lathes, drilling machines, etc., to perform cutting, milling, drilling, and other tasks.

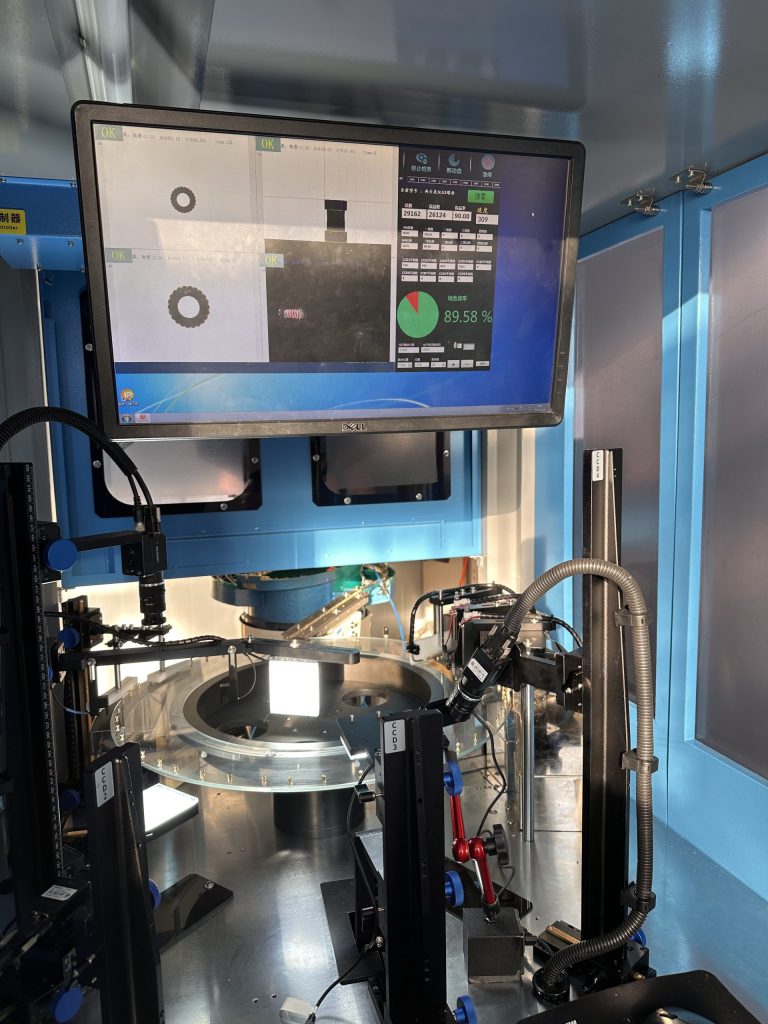

4. Quality Inspection: After machining, each part undergoes dimensional and tolerance checks to ensure it meets standards.

5. Delivery and After-Sales: After final inspection, all parts are delivered on time. If customers have any questions, we provide timely after-sales service.

Small-Batch and Large-Batch Production

Whether it is rapid production of a single prototype part or large-scale production, we provide flexible machining solutions. By optimizing production scheduling and using efficient equipment, we ensure that production cycles and delivery times are met while maintaining quality.

Quality Control

Our quality management system ensures that every part undergoes strict inspection during machining. Each part is measured for dimensions, checked for appearance, and verified for functionality to ensure it meets design requirements. Additionally, we monitor any deviations that may occur during the production process in real-time and make adjustments promptly.

Delivery and Response Time

By properly arranging the production process, we ensure on-time delivery for both standard orders and urgent requests. We offer quick responses and flexible delivery times according to customer needs.