How to Perform Post-Welding Repair?

Welding defects such as porosity, cracks, and lack of fusion may occur even when the welding process is properly controlled. To ensure structural safety and product quality, timely and standardized post-welding repair is crucial. This article will detail the standard post-welding repair process, key points in each step, and precautions to help reduce rework costs and improve welding quality.

Table of Contents

Post-Welding Repair Process

1. Defect Detection and Confirmation

Before starting post-welding repair, it is essential to first confirm the type and location of the welding defects.

2. Development of Repair Plan

Once the defects are identified, a detailed repair plan must be developed. The repair plan includes the repair method, welding process, materials to be used, equipment setup, and other relevant details. It is usually necessary to develop the plan based on the Welding Procedure Specification (WPS) to ensure that the post-repair welding process is consistent with or optimized from the initial welding procedure.

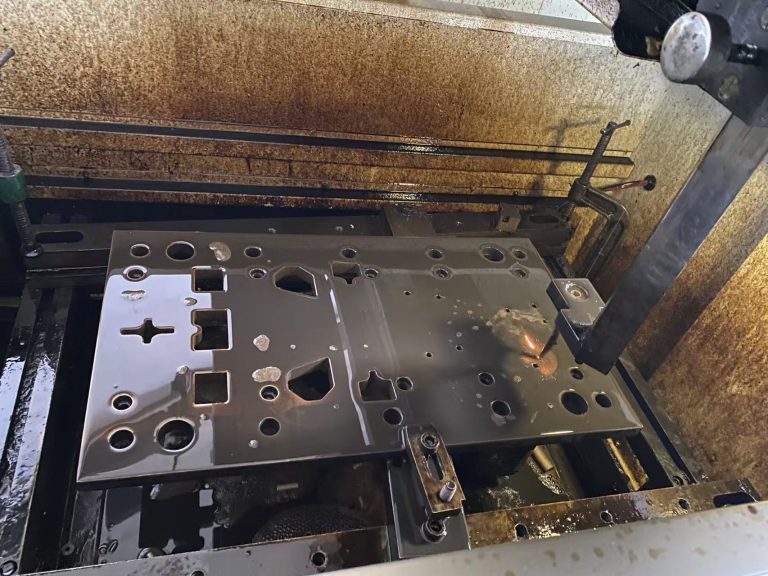

3. Preparation Work for Repair

Preparation work before repair is crucial. First, the defective area must be cleaned to remove oxides, oil, and other contaminants. Common cleaning methods include hand grinding or using carbon arc gouging. Then, check whether all required tools and equipment are available and whether the groove design meets the requirements to ensure the quality of the repair welding.

4. Post-Welding Repair Operations

During the repair welding process, it is essential to strictly follow the repair plan. This includes setting the correct welding parameters such as current, voltage, wire feed speed, etc. For more complex defects, layered welding or controlling heat input may be necessary to reduce the potential for new defects during the welding process.

5. Post-Repair Inspection and Acceptance

Once the repair is complete, the relevant inspections must be carried out to ensure that no new defects have occurred in the repaired weld. In most cases, the repaired area will undergo Non-Destructive Testing (NDT) to confirm the welding quality. Only after passing the inspection can the repaired part be put into use or delivered to the customer.

Common Post-Welding Repair Pitfalls

Although post-welding repair is a key step in ensuring product quality, there are still some common pitfalls in practice that need to be avoided. For example, some welders may choose to simply grind the weld to cover up the problem instead of thoroughly repairing the defect. In addition, failure to follow process specifications or strict inspection procedures during the repair can lead to repair failure.