Creating a Metal Stamping Prototype

Creating a metal stamping prototype transforms an initial concept into a physical model, a process essential for verifying that the prototype adheres to all design and functional criteria before it advances to mass production. Below is a streamlined overview of this process:

Initial Consultation and Design Evaluation: The process begins with understanding client needs and performing a technical evaluation to ensure the design’s feasibility.

Design and Client Approval: Based on the initial consultation, a preliminary design is created and refined until it receives client approval.

Material Selection: Choosing the right material is crucial for the prototype’s functionality. We select materials based on the part’s requirements and the environment in which it will operate.

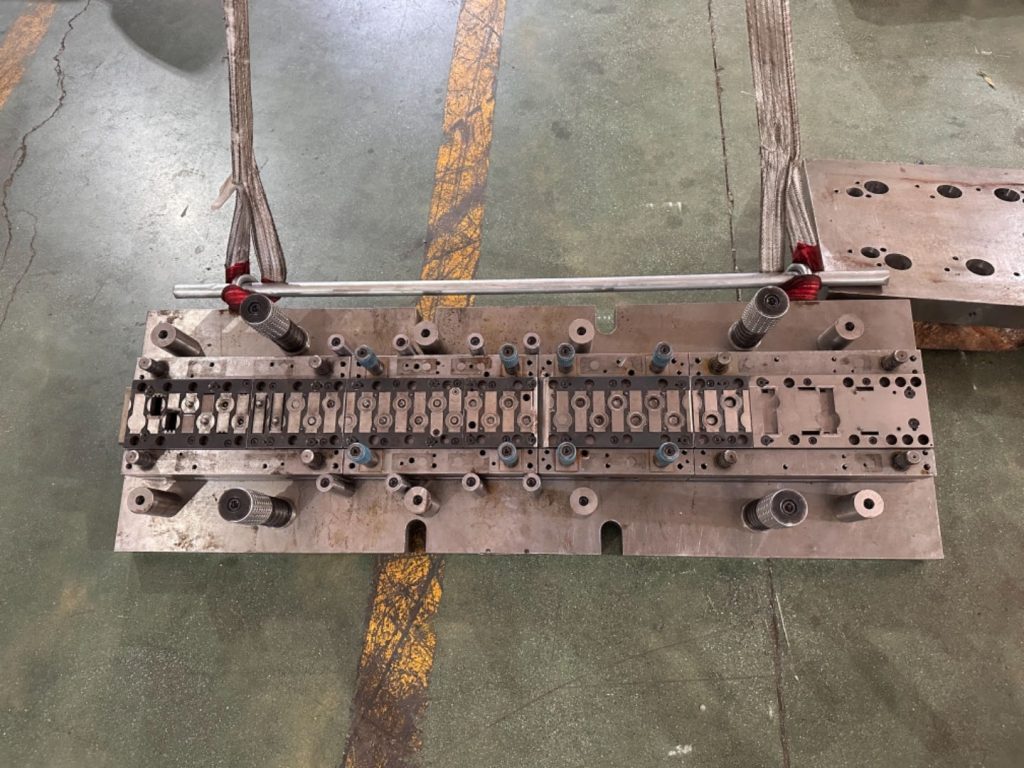

Tool and Die Fabrication: With the design in place, we proceed to develop the specialized tools and dies necessary for stamping, focusing on precision and quality.

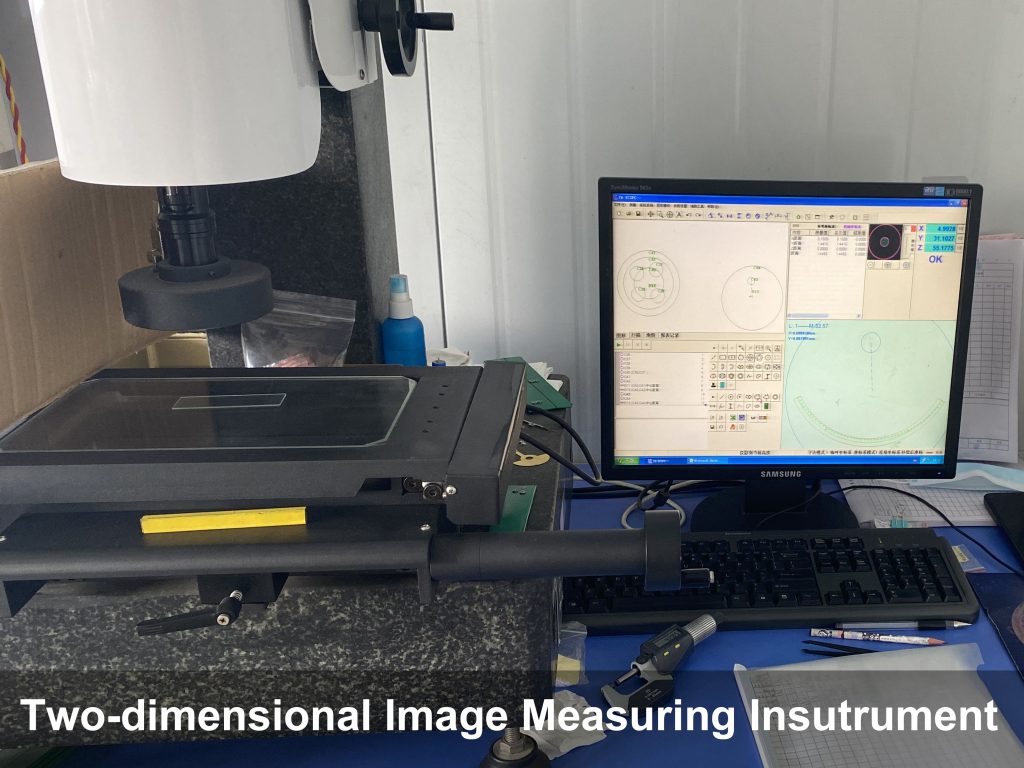

Quality Assurance and Testing: The prototype undergoes thorough quality checks and performance testing to ensure it meets design specifications.

Client Review and Feedback: The prototype is then reviewed by the client, whose feedback may lead to further refinements, optimizing the design for both performance and manufacturability.

Finalization for Mass Production: After the prototype is finalized and approved, the project moves towards mass production preparation.

Metaco aims to offer a complete manufacturing link, eliminating intermediate processes to save costs and enhance precision. If necessary, we can also integrate additional machining operations, along with providing high-quality surface treatments. Should you require prototype production, please contact us.