Sampling Suggestions For Metal Fabrication

For OEMs, whether it’s a newly designed part or a reverse engineered part, sampling is a necessary step before mass production. How do you communicate with your suppliers about sampling?

First, share your plan with the supplier, including the project schedule, annual usage, and the progress of the part. The sharing of this information will give the supplier a reasonable expectation so that the supplier can prepare appropriately. For different expectations, the supplier can provide different options to optimize the cost of sampling.

The next step is to provide a detailed and informative drawing with the necessary descriptions. This is because drawings in general often do not make the considerations for the part completely clear. Especially before mass production, including tolerances and fits, surface finish requirements, etc. may not be clear, you can let the supplier make suggestions.

Third, prioritize your requirements. Not all requirements have the same priority, and prototyping is the process of verifying and clarifying these requirements. Sampling helps to optimize the design and obtain the most economical and technically sound design.

Overall, adequate communication not only gains the supplier’s understanding and support, but also optimizes the design of the part to improve reliability and reduce costs.

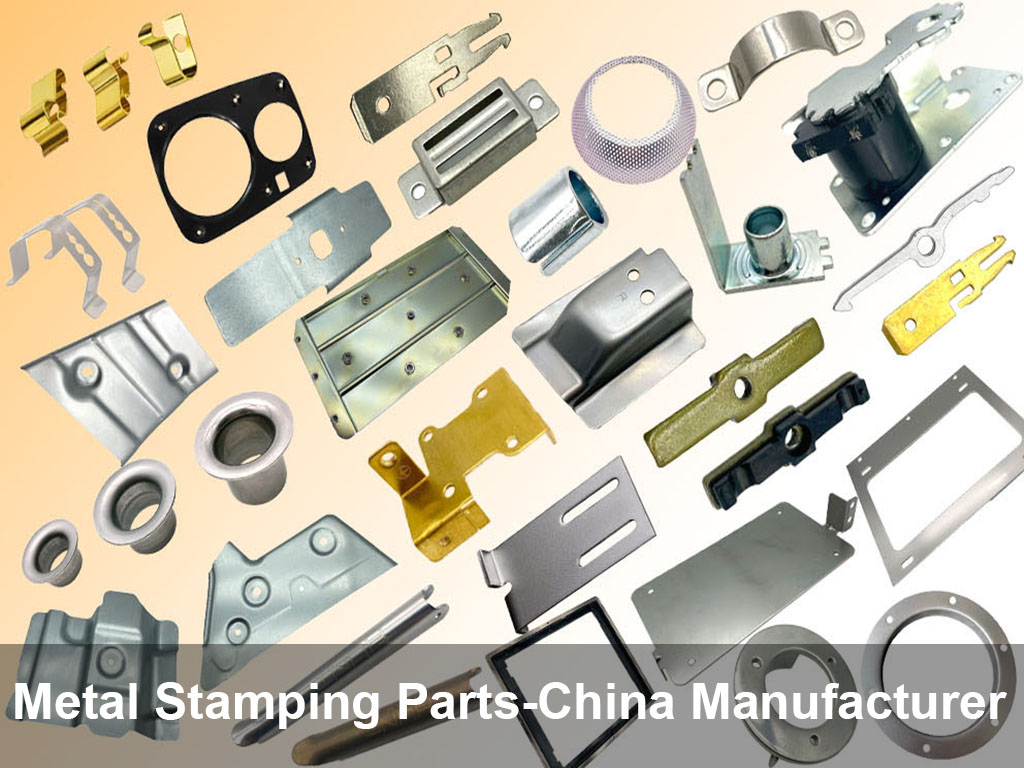

Metaco has extensive experience in welding and stamping and can provide fast and professional technical communication for your prototyping requirements. Our resources in metal fabrication are also available to support a smooth prototyping process.