Transfer Stamping-Wire Harness Metal Bracket

- Part name: Wire Harness Metal Bracket

- Manufacturer: Metaco-Stamping solutions

- Stamping tool: Transfer Die

- Application: Automotive industry

- Material: SPCC

- Material thickness: 1.5mm

- Material width: 110mm

- Material step: 42.9mm

- Process: Punching cutting, Bending forming

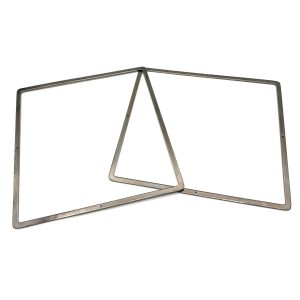

Stamping Tool And Die

The production of the Wire Harness Metal Bracket employs a focused two-step stamping process, consisting of blanking and forming stages. Our tooling is optimized for clean cuts, reducing material waste and ensuring that each piece is prepared with exact dimensions for the subsequent forming step.

By minimizing tool wear and maximizing reusability, we achieve a reduction in die costs, providing a cost-effective manufacturing solution without compromising on the quality or accuracy of the final product.

This process is designed to ensure the bracket is crafted with the required precision for its application in the automotive industry.

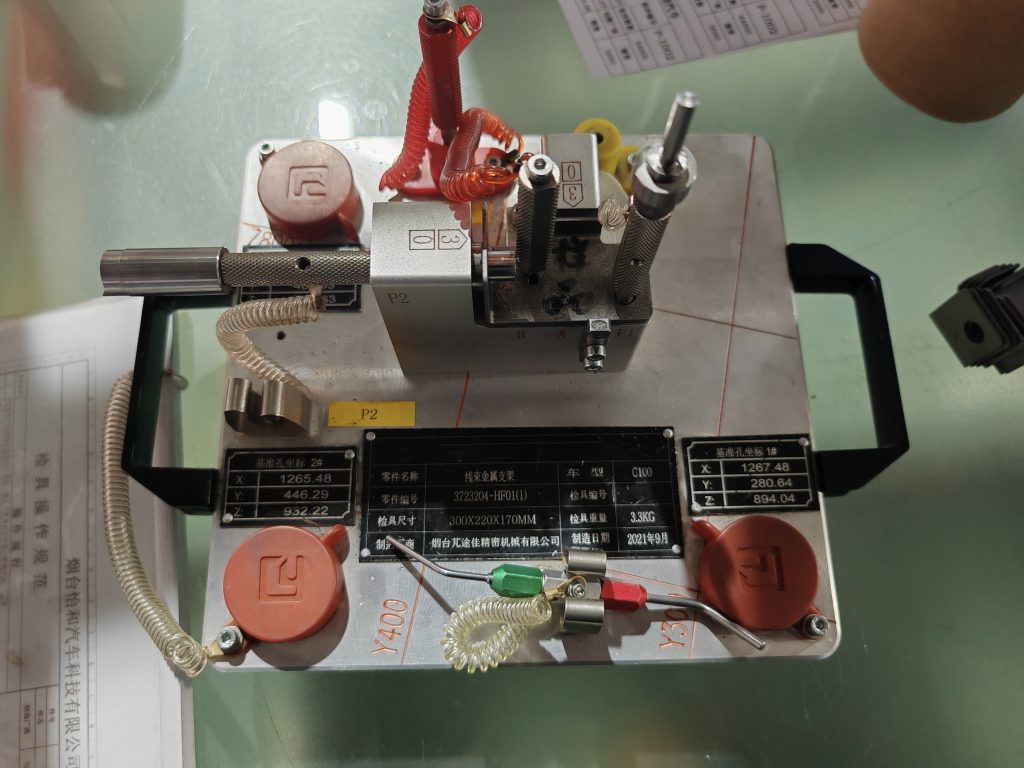

Automatic Stamping Press

The Press for manufacturing the Bracket is equipped with a specialized part receiver for collecting parts after blanking.

This device collects the brackets as they are stamped from SPCC material, ensuring efficient transition without manual handling. Its role minimizes downtime and supports continuous production flow.

The automated part receiver increases throughput, reduces the risk of damage to components, and maintains consistent product quality. It also enhances workplace safety by eliminating manual collection tasks.