Sheet Metal Stamping Tolerances: How to Ensure Precision and Why They Matter

When it comes to sheet metal stamping , tolerances are a critical aspect of the process. Tolerances refer to the acceptable range of deviation from a specified dimension or measurement. Ensuring that tolerances are within acceptable limits is essential for achieving precision and consistency in the final metal stamping product.

Table of Contents

How to Ensure Precision in Sheet Metal Stamping Tolerances

To ensure precision in sheet metal stamping tolerances, several factors need to be considered, including the material being stamped, the type of stamping process, and the tooling used. Here are some tips to help ensure precision in sheet metal stamping tolerances:

Design with tolerances in mind

When designing a sheet metal stamping product, it is crucial to consider the tolerances required for the product to function properly. This includes specifying the appropriate tolerances for critical dimensions, such as hole sizes and thicknesses.

Use appropriate tooling

The tooling used in sheet metal stamping must be precise and well-maintained to ensure that the stamped parts meet tolerances. Tooling that is worn or damaged can result in parts that are out of tolerance and unusable.

Select the right stamping process

Different sheet metal stamping processes have different tolerances, so it is essential to select the right process for the product being produced. For example, some processes, such as progressive die stamping, can achieve tighter tolerances than others.

Control material thickness

Material thickness can impact tolerances, so it is important to monitor material thickness throughout the metal stamping process to ensure that it remains within the required tolerances.

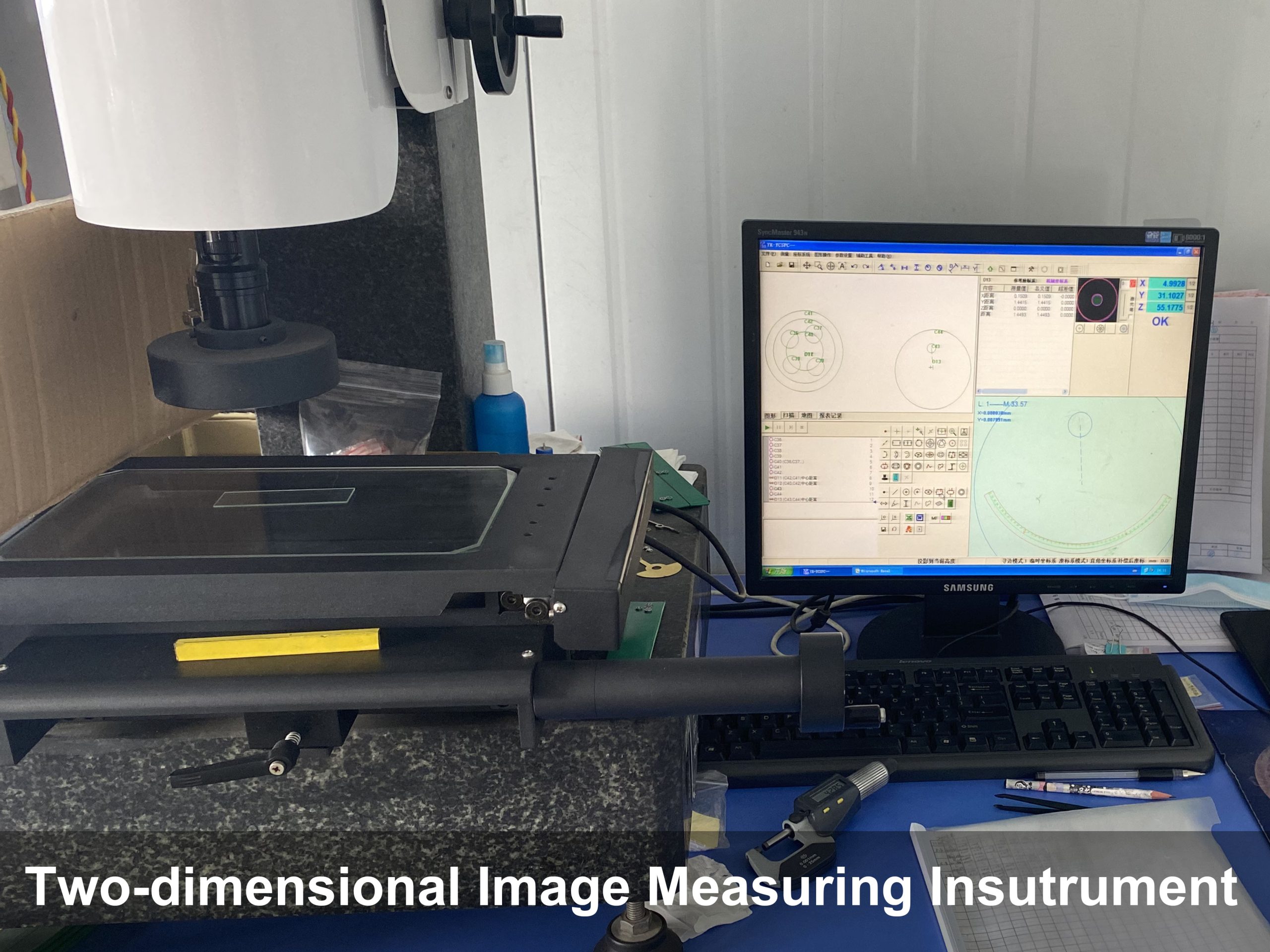

Conduct regular quality checks

Regular quality checks can help catch any deviations from tolerances early on in the automotive metal stamping process. This can help prevent costly rework or scrap and ensure that the finished product meets customer requirements.

Why Tolerances Matter in Sheet Metal Stamping

Tolerances determine the fit and function of the final product. If tolerances are too loose, parts may not fit together properly or may not perform as intended. If tolerances are too tight, parts may not be manufacturable, or they may require additional time and cost to produce. Tolerances also play a critical role in ensuring product quality and meeting customer requirements. If a product has tighter tolerances, it is generally considered to be of higher quality, as it is more precise and consistent.

Sheet metal stamping tolerances are a critical aspect of the metal stamping process. They determine the fit and function of the final product and play a crucial role in ensuring stamping products quality and meeting customer requirements.