Four Basic Processes of Stamping

Stamping is a manufacturing process that involves cutting, forming, and shaping metal sheets into various shapes and sizes. There are four basic processes involved in stamping: blanking, piercing, bending, and drawing. In this post, we will explore each process in detail.

Table of Contents

blanking

Blanking is the process of cutting a flat piece of sheet metal into a desired shape. A blank is the piece of metal that remains after the cutting process. Blanking is used to create simple shapes like squares, rectangles, and circles.

To create a blank, a metal sheet is placed on a die that has the desired shape. A punch then presses down onto the metal sheet, cutting it into the desired shape. The scrap metal is then removed, leaving behind the blank.

piercing

Piercing is the process of cutting a hole or multiple holes in a metal sheet. A punch is used to pierce the metal sheet, which can be a standalone process or combined with blanking.

The punch is placed on the metal sheet where the hole is to be made, and then a press is used to push the punch through the sheet. The scrap metal is then removed, leaving behind the hole.

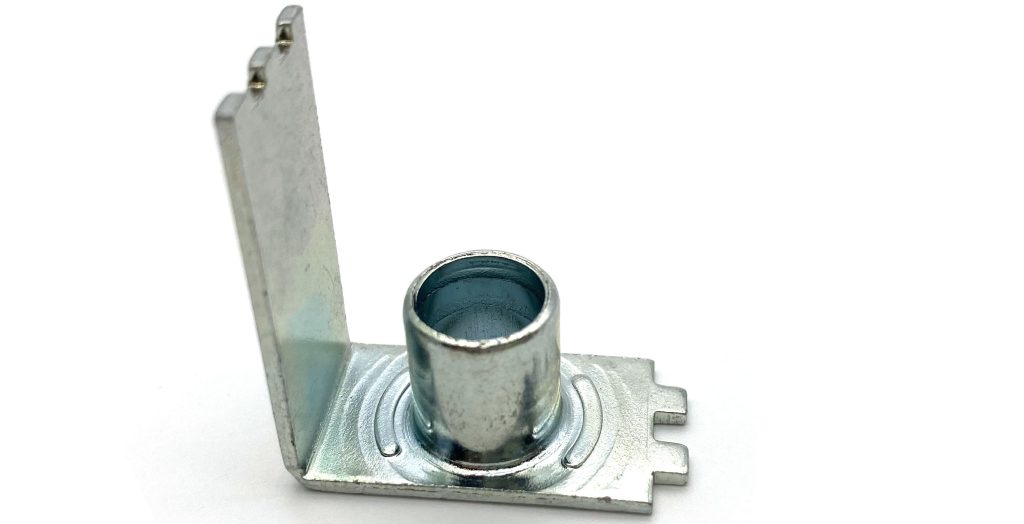

bending

The bending process involves deforming a metal sheet into a curved shape using a punch and a die. The punch is a tool that applies force to the metal sheet, while the die provides a support surface for the metal sheet to bend around. The bending process can be performed using either a V-bend or a U-bend die.

To achieve accurate and precise bends, it is essential to consider various factors such as the thickness and material properties of the metal sheet, the shape and dimensions of the die and punch, and the force applied during the bending process.

drawing

Drawing is the process of shaping a flat piece of metal into a three-dimensional shape. This process involves pulling the metal sheet through a die, which stretches and forms the metal sheet into the desired shape.

To begin the drawing process, a metal sheet is placed over a blankholder, which is a circular device that holds the metal sheet in place. A punch is then used to force the metal sheet through a die, which stretches and shapes the metal sheet into the desired shape.

Stamping is a versatile manufacturing process that involves four basic processes: blanking, piercing, bending, and drawing. These processes can be combined to create complex shapes and designs, making stamping a popular choice for industries such as automotive, aerospace, and construction.