What types of stamping process are available

When it comes to sheet metal fabrication, stamping processes play a crucial role in creating a wide range of products with precision and efficiency. Stamping involves using a punch and die to deform sheet metal into the desired shape, and there are various types of stamping processes available to meet different manufacturing needs. Let’s explore some of the common stamping processes in more detail.

Table of Contents

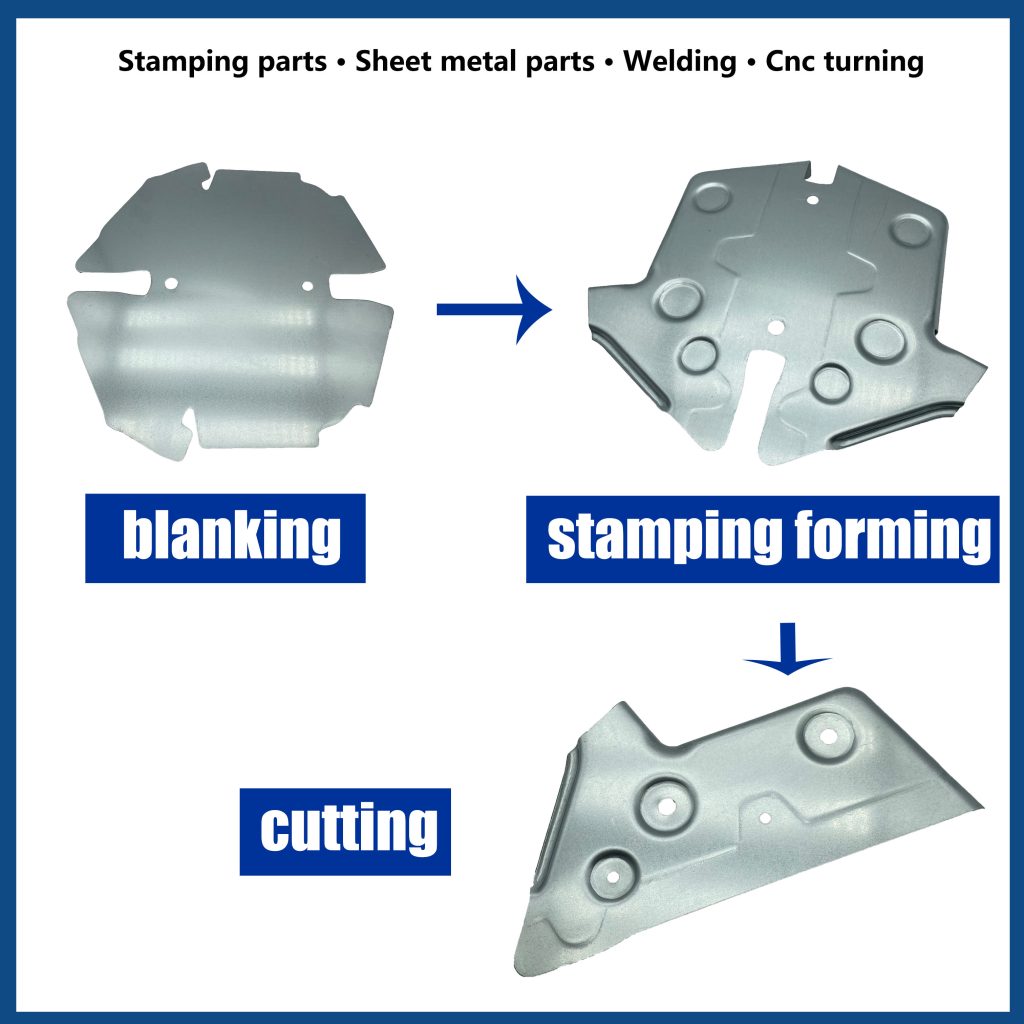

Blanking

Blanking is a straightforward stamping process that involves cutting a flat piece of sheet metal into a desired shape, typically with a single cutting operation. It is commonly used to create flat, simple shapes, such as circles or rectangles, and is often the first step in the manufacturing process for many sheet metal components.

Piercing

Piercing is similar to blanking, but it involves cutting holes or openings in sheet metal using a punch and die. It is used to create perforated sheets, ventilation holes, or other types of openings in sheet metal components.

Bending

Bending is the process of deforming sheet metal into a desired shape using a punch and die. It is commonly used to create bends, angles, and curves in sheet metal components, and it can be performed using a variety of techniques, such as air bending, bottom bending, or coining.

Forming

Forming is a stamping process that involves deforming sheet metal into a three-dimensional shape using a punch and die. It is used to create complex shapes, such as automotive body panels, kitchen appliances, and electronic enclosures. Forming can be done using different techniques, such as deep drawing, stretch forming, or roll forming, depending on the requirements of the part being manufactured.

Coining

Coining is a stamping process that involves compressing sheet metal between a punch and die to create a precise, detailed impression on the surface of the metal. It is often used to create decorative or functional features, such as logos, lettering, or textured surfaces on sheet metal components.

Embossing

Embossing is similar to coining, but it involves raising the surface of the sheet metal to create a raised design or pattern. It is commonly used for decorative purposes, such as on nameplates, signage, or packaging materials, to add visual appeal or create branding elements.

Drawing

Drawing is a stamping process used to create deep, cup-shaped parts from sheet metal. It involves pulling the sheet metal into a die cavity using a punch and is often used to produce items such as cans, cups, or containers.

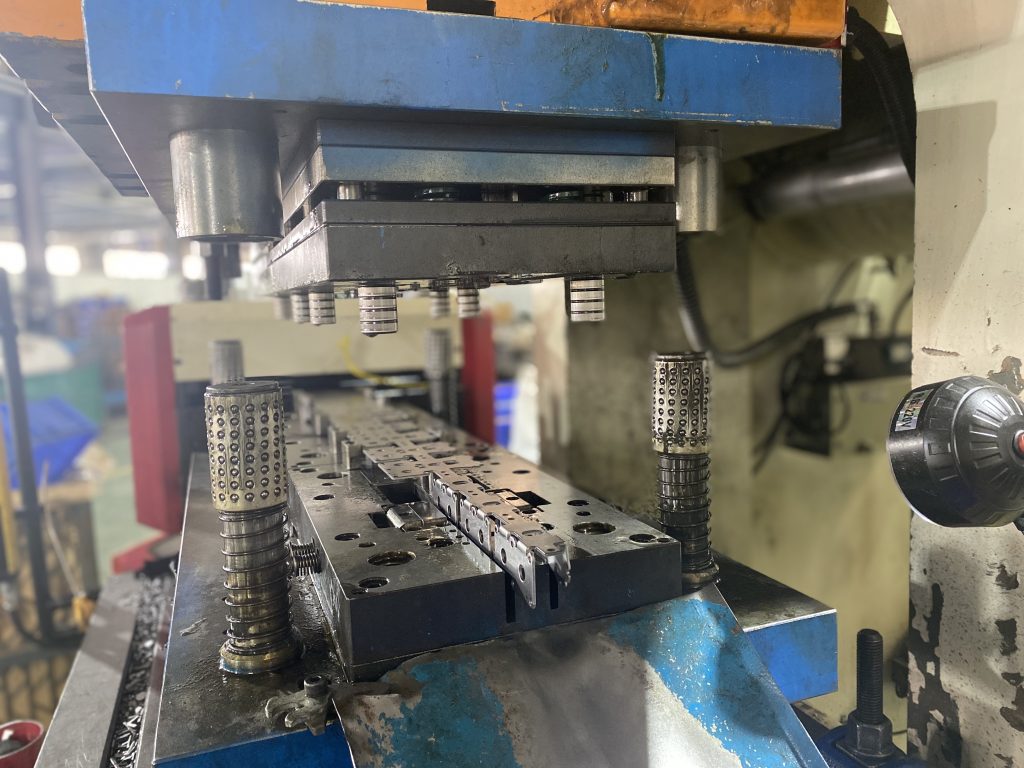

Progressive Die Stamping

Progressive die stamping is a high-speed stamping process that uses multiple dies to perform multiple operations on a single sheet of metal as it moves through a press. It is commonly used for high-volume production of small, intricate parts, such as electrical connectors, fasteners, or automotive components. Progressive die stamping offers high efficiency, repeatability, and cost-effectiveness in producing complex parts.

Hydroforming

Hydroforming is a stamping process that uses fluid pressure to shape sheet metal into complex shapes. It is often used for producing lightweight, high-strength parts with minimal tooling and material waste, such as in the aerospace and automotive industries. Hydroforming allows for the creation of intricate, seamless parts with reduced post-processing requirements.

Laser Cutting

Laser cutting is a non-contact stamping process that uses a high-powered laser beam to cut through sheet metal. It is precise and allows for intricate designs, and is commonly used for cutting complex shapes, holes, or patterns in sheet metal. Laser cutting offers flexibility in design and is suitable for both prototyping and production runs.

These are just a few examples of the many types of stamping processes available, and the appropriate method depends on the specific requirements of the part or product being manufactured.