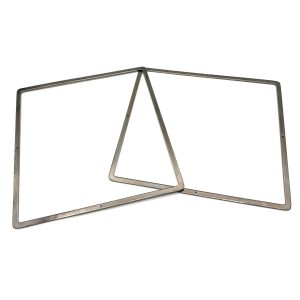

Stainless Steel Stamping-High-Temperature Sensor Mount

- Part name: High-Temperature Sensor Mount

- Manufacturer: Metaco-Stamping solutions

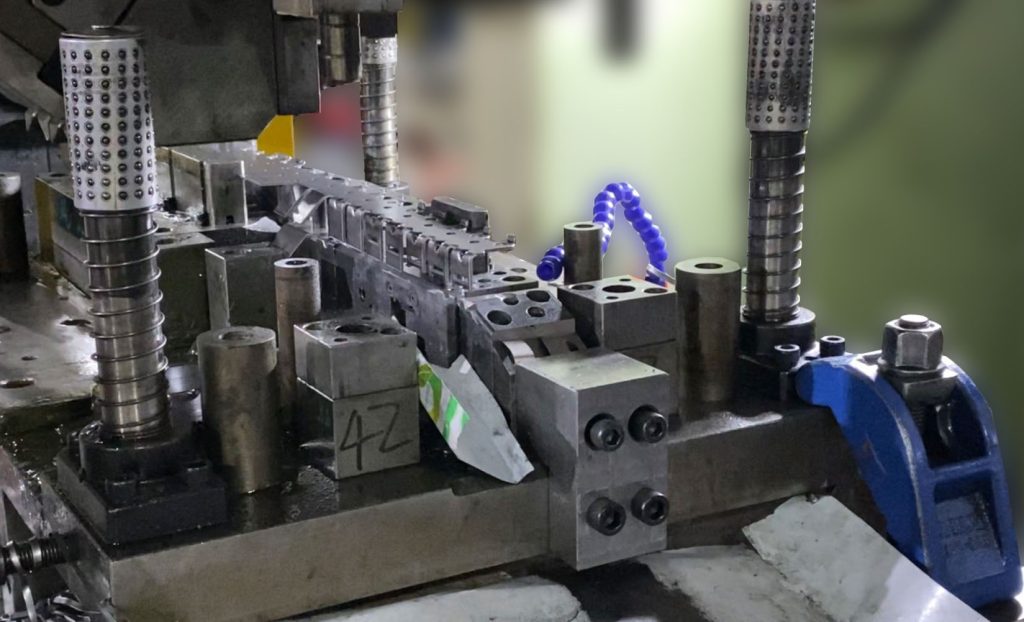

- Stamping tool: Progressive die

- Application: Automotive industry

- Material: SPCC

- Material thickness: 2mm

- Material width: 70mm

- Material step: 30.5mm

- Process: Punching, Fine blanking, Bending, Cutting

- Tolerance: 0.05mm to 0.1mm

Sensor Mount Stamping die Design

The progressive die stamping process for the High-Temperature Sensor Mount enhances manufacturing efficiency and component precision. Metaco oversees all phases of die management, including design, production, setup, and maintenance, ensuring tool longevity and performance. The die incorporates a blow-off system for part ejection, directly controlling part trajectory and placement to mitigate collision and stacking.

Sensor Mount Stamping press operation

The High-Temperature Sensor Mount is the eleventh custom component Metaco has prototyped for this automotive client. Following the completion of the mold, we determine the appropriate press for production. Our facility is equipped with both high-speed presses, achieving up to 400 strokes per minute, and heavy-duty presses with a capacity of up to 300 tons. Metaco’s automated stamping spans material feed, stamping, and ejection processes, optimizing stamping throughput and ensuring part quality.

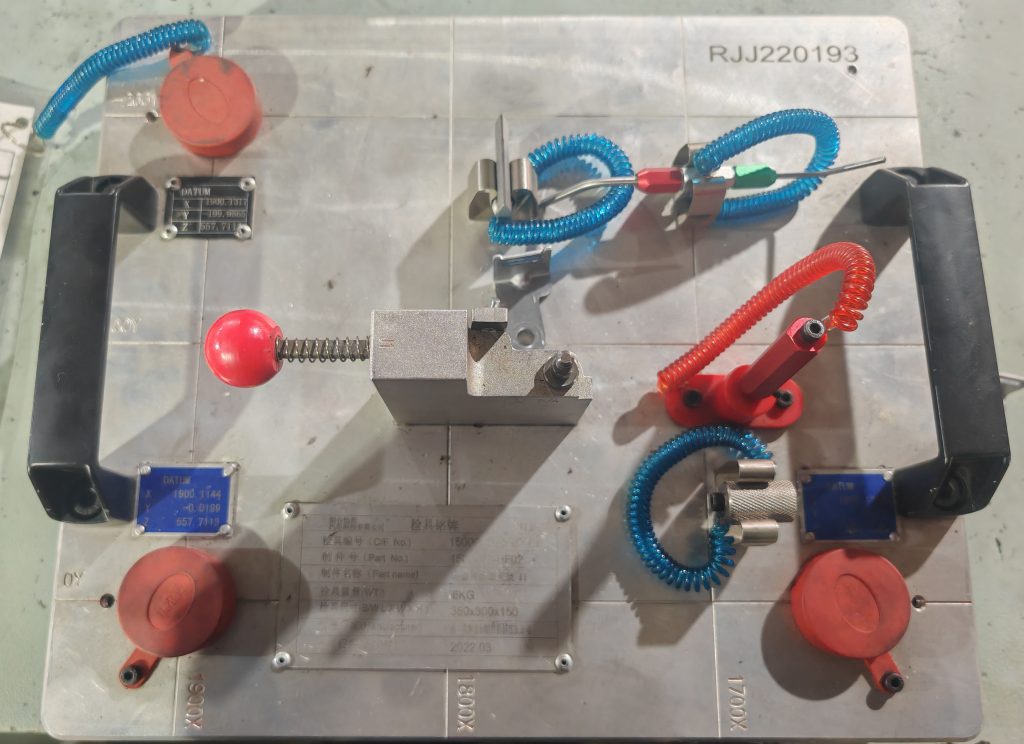

Sensor Mount stamping quality inspection

For the Metal Stamping Quality Inspection of the High-Temperature Sensor Mount, Metaco establishes quality inspection protocols based on client requirements. From the point of manufacture to after the product is put into use, dedicated personnel are responsible for managing quality issues, by activating contingency plans or developing solutions.