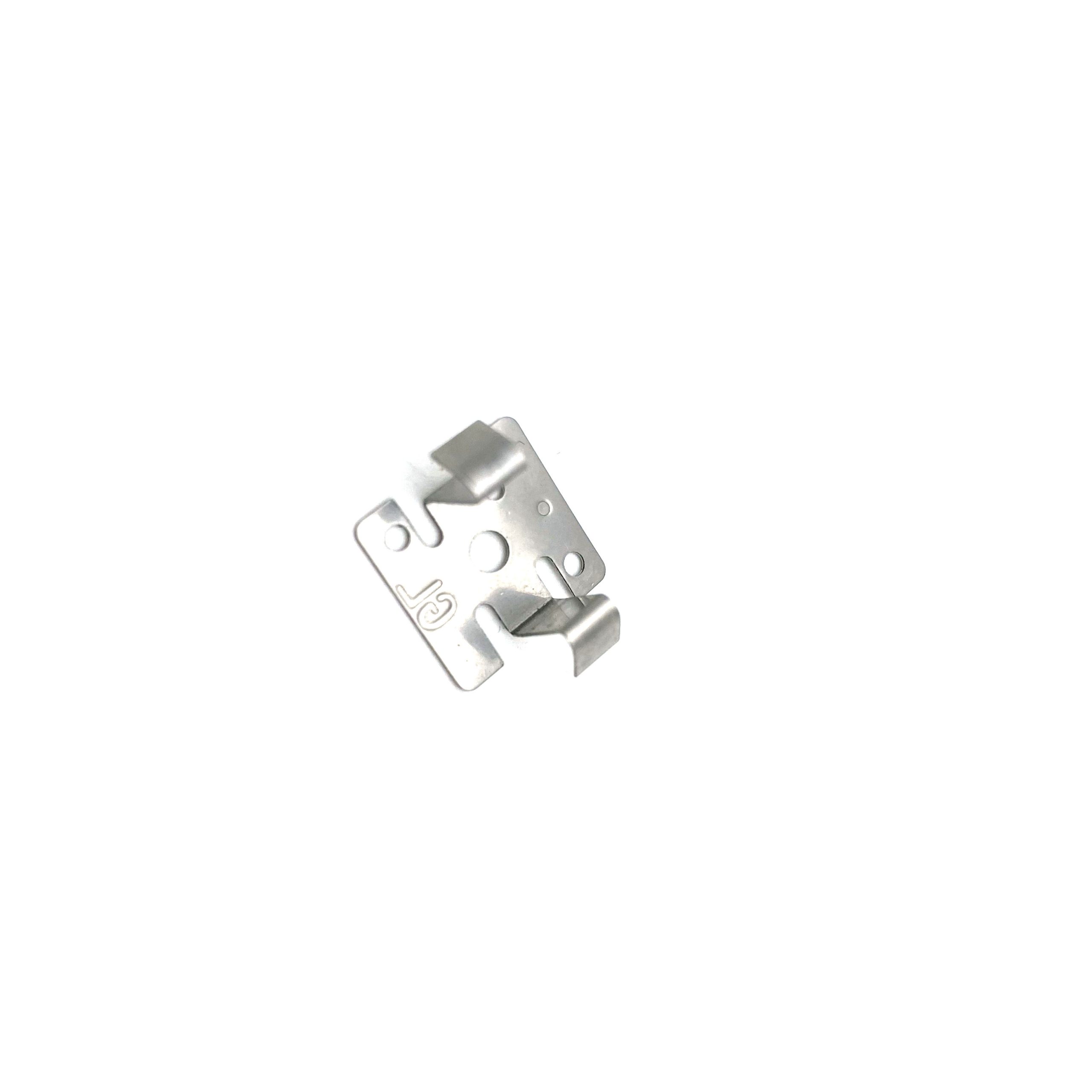

Micro Precision Stamping Automotive Stopper

- Part name: Automative stopper

- Manufacturer: Metaco-Metal Stamping Supply Chain Manager

- Application: Automotive industry

- Material: SUS 304 stainless steel

- Process: Punching, Fine blanking, Bending, Stamping forming, Cutting

- Tolerance: 0.05mm to 0.1mm

- Stamping tool: Progressive die

Progressive stamping process

In-house stamping tool design, professional progressive die design and manufacturing team. This part is used as a stopper in the car. The precision requirements are not very high, so the die-making cycle time is about half a month. However, there are V-shaped contact angles on both sides of the part, which require high precision in the opening dimensions. Therefore, the part underwent multiple tests and adjustments before entering production.

Stamping material selection

In automotive parts stamping, stainless steel is often the material of choice. We have long-term collaborations with material suppliers, allowing us to procure steel strips based on customer requirements and production volume.

High-volume stamping

We have achieved fully automated stamping, with a daily production capacity of 20,000 stoppers. If you have custom stamping needs, please contact us for a quote.