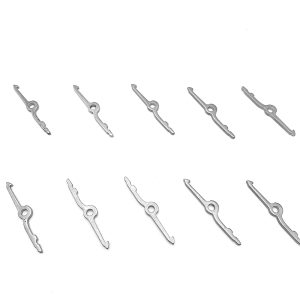

Electro-galvanized stamping Reflector Plate R Front

- Part name: Reflector Plate R Front

- Manufacturer: Metaco-Stamping solutions

- Application: Automotive industry

- Material: Tinplate (SPTE) Cold-rolled thin steel sheet with a thin layer of metallic tin plated on the surface.

- Process: Punching, Fine blanking, Bending, Stamping forming, Cutting

- Tolerance: 0.05mm to 0.1mm

- Stamping tool: Progressive die

Stamping manufacturing process

Material Selection: Utilizes SPTE, characterized by its exceptional formability, ideal for the automotive environment.

Precision Punching & Fine Blanking: These processes are critical for achieving the intricate details and exacting dimensions required, employing advanced machinery that ensures high fidelity to design specifications.

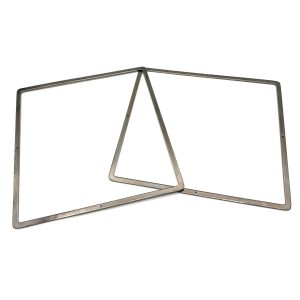

Stamping die design

Progressive Die: This tooling solution is engineered for sequential operations, allowing multiple stamping tasks—such as cutting, forming, and bending—to be executed in a single pass through the press. This not only enhances production efficiency but also ensures uniformity and precision across large production volumes.

CAD/CAM Integration: Utilized for die design, enabling sophisticated simulations of the stamping process, predictive tool wear analysis, and optimization of die geometry for minimal material wastage.

Tooling Material Selection: High-grade tool steels are selected for their durability, wear resistance, and ability to maintain dimensional stability under high-stress conditions.

Metal stamping process control

Tolerance Control: Specifications are rigorously maintained within a 0.05mm to 0.1mm range, utilizing precise measurement instruments and SPC (Statistical Process Control) methods to monitor and adjust the process in real-time.

Quality Assurance Protocols: Include dimensional inspections, material property testing, and surface finish evaluations at critical production stages to ensure compliance with automotive industry standards.

Process Optimization: Continuous monitoring of process variables such as press speed, material feed rate, and tool temperature to mitigate the risk of defects and ensure optimal production efficiency.