Hot-dip Galvanized Plate Stamping for Front Fender Bracket

- Part name: Front Fender Bracket

- Manufacturer: Metaco-Stamping solutions

- Application: Automotive industry

- Stamping tool: Progressive die

- Material: Hot-dip Galvanized Plate (DQ)

- Material thickness: 0.8mm

- Material width: 68.6mm

- Material step: 49mm

- Process: Punching, Fine blanking, Bending, Stamping forming, Cutting

- Tolerance: 0.05mm to 0.1mm

Metal Stamping Tools

Our Front Fender Bracket utilizes progressive die stamping tools with automatic feeding, enabling dual-component production per press cycle. This setup increases throughput while ensuring consistent part quality.

Stamping Operations

We employ a fully automated stamping process, using hot-dip galvanized plate (DQ), its corrosion resistance and lower production costs compared to electro-galvanized materials. Challenges such as imprints, variations in the zinc layer, and the risk of white rust and black spots with prolonged exposure are systematically managed to maintain product quality.

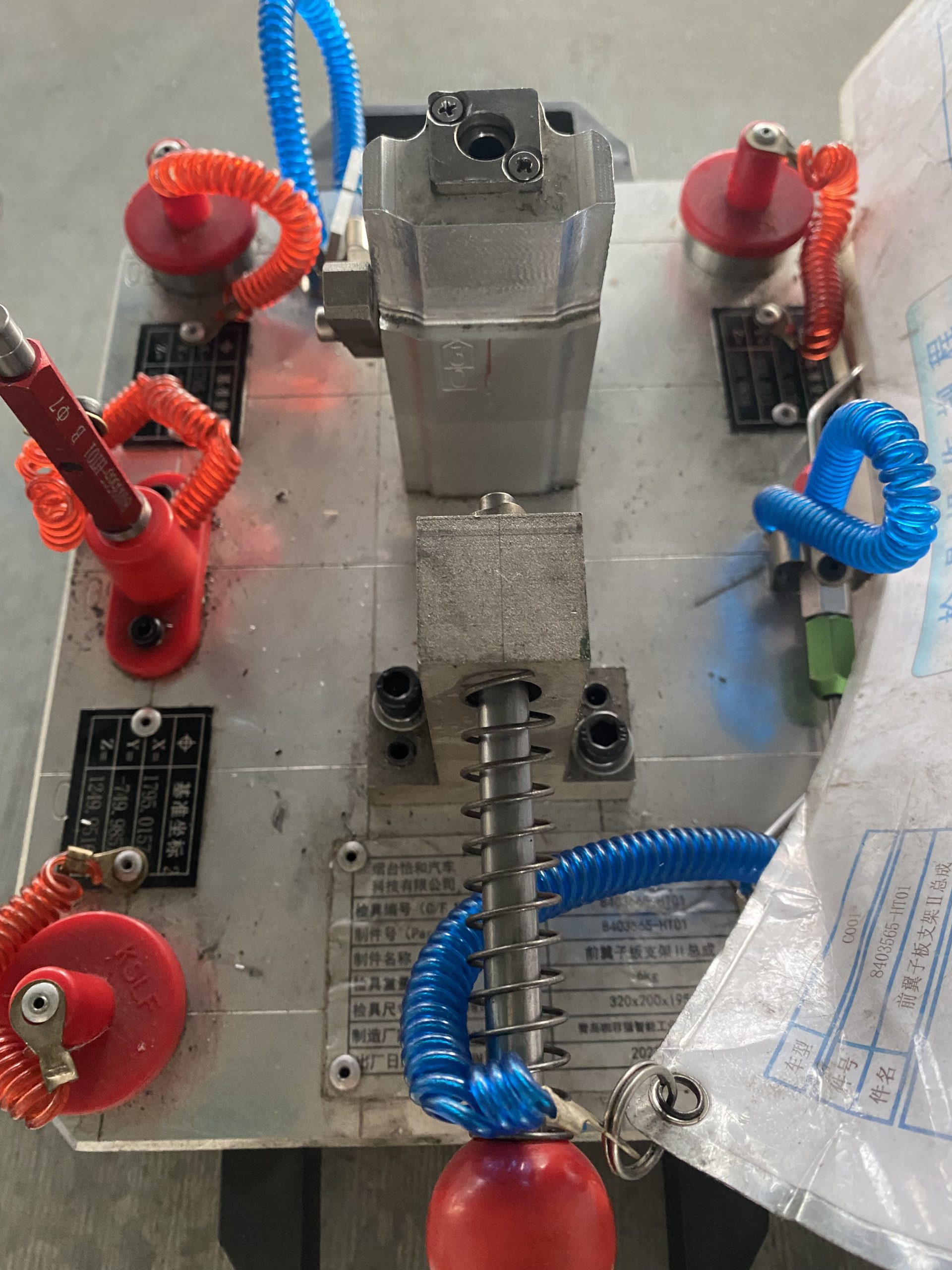

Metal Stamping Quality Assurance

Quality assurance is certified to TS16949 standards. Our protocol includes using specialized inspection fixtures and dedicated quality inspectors for real-time monitoring throughout the stamping process. This ensures all parts meet the specified tolerances of 0.05mm to 0.1mm, aligning with requirements for precision in automotive applications.