What kinds of metal fabrication parts are suitable for out sourcing from China?

If you are an OEM and need metal fabrication parts to be out sourced, to source from China is a good idea. China has resources in various materials, manufacturing processes, experienced labor, surface treating and packaging. For parts with large volume and demands low cost, to source from China is a must. With the trend of tumbling sea shipping costs, to source from China becomes more feasible. What features make metal fabrication parts suitable for sourcing from China?

welding fabrication by welder

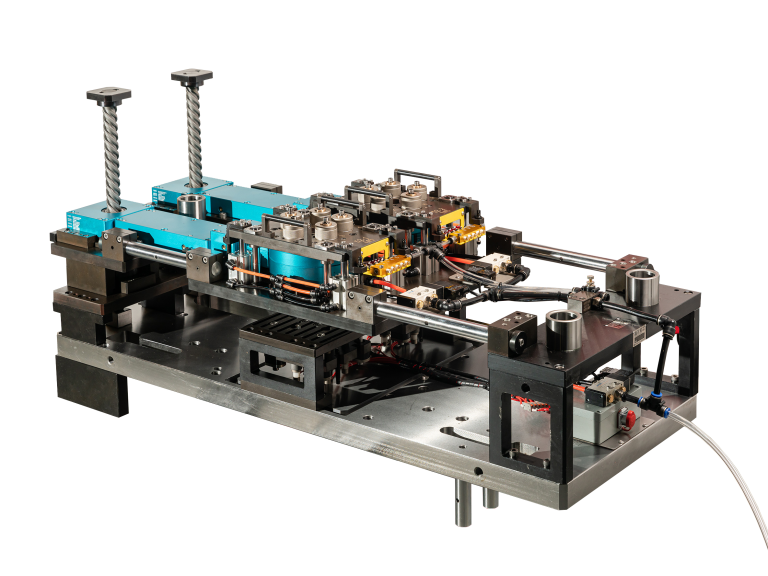

welding fabrication by welder Stamping die in the metal stamping china workshop and ready to be mounted on the press.

Stamping die in the metal stamping china workshop and ready to be mounted on the press.

Table of Contents

Parts with less time-efficiency

As an OEM, to streamline the supply chain and to meet production demand is essential, and time-efficiency is a must for consideration.To ship by sea from China to America or Australia takes average 30 days for shipping to collection.

High labor-added parts

Average welder salary in China is from USD 3 to 6 per hour, depending on welding experience. Comparing to America and Australia, this is very competitive.

Parts with high value per unit weight/volume

The sea shipping cost and related handling costs must be taken into consideration comparing with sourcing from local, as well as customs tariff.

Parts with regular purchasing plan

A regular purchasing plan will lower the need for time-efficiency and it increases the contract manufacturer’s motivation.

In the end, to find a proper contract manufacturer is the key solution.