Assembly Parts: The Importance of Coordination between Stamping and Other Processing Processes

In the manufacturing industry, assembly parts are often produced using a combination of different processes, such as stamping, welding, machining, and coating, to create the final product. Among these processes, stamping plays a crucial role in shaping and forming metal sheets into specific components or parts. However, to achieve a seamless and efficient manufacturing process, coordination between stamping and other processing processes is essential.

Stamping, which involves cutting, bending, and forming metal sheets using dies, requires precision and accuracy to produce high-quality parts. These stamped parts then go through subsequent processes, such as welding, machining, and coating, to further refine and assemble them into the final product. Coordination between these processes is critical to ensure that the stamped parts are compatible with other components, and that they fit together seamlessly during assembly.

Table of Contents

design and engineering stage

One key aspect of coordination between stamping and other processing processes is the design and engineering stage. Proper consideration of tolerances, material properties, and process capabilities during the design phase is crucial. For example, stamping processes may introduce certain tolerances or dimensional variations, which need to be taken into account in subsequent processes. Coordination between the design and engineering teams, as well as the stamping and other processing teams, is necessary to ensure that the stamped parts are manufactured to the correct specifications and are compatible with other components.

material selection and preparation

Another aspect of coordination is the material selection and preparation. Different materials may require specific processing techniques, and the material properties can affect the stamping process as well as subsequent processes. For instance, materials with higher strength or hardness may require specialized tooling or machining processes, while materials with surface coatings may require pre-treatment or post-treatment steps. Proper coordination and communication between the stamping and other processing teams are necessary to ensure that the material properties are considered and appropriate processes are applied accordingly.

quality control and inspection

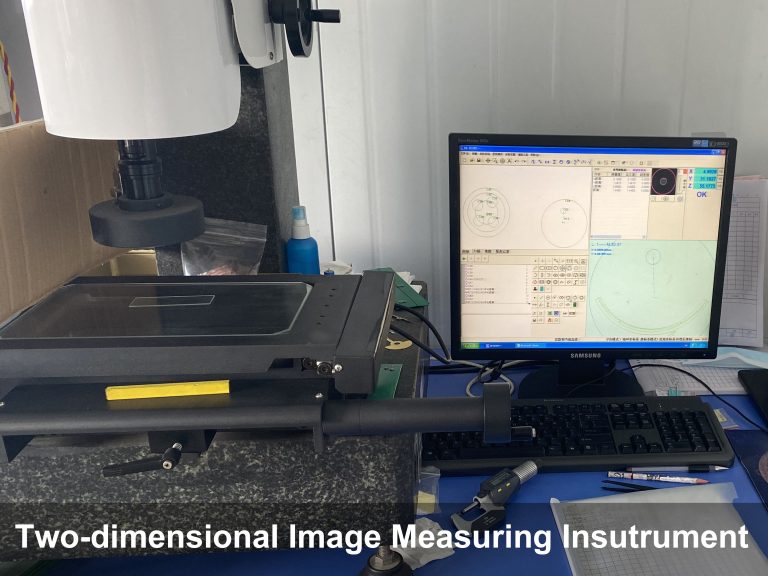

Additionally, quality control and inspection are crucial in coordinating between stamping and other processing processes. Inspection of the stamped parts for dimensional accuracy, surface finish, and other quality characteristics is important to catch any potential issues early on in the manufacturing process. If any discrepancies are found, communication and coordination between the stamping and other processing teams are necessary to address and resolve the issues promptly to avoid delays or rework.

scheduling and production planning

Furthermore, scheduling and production planning are essential in coordinating between stamping and other processing processes. Each process may have its own lead times, cycle times, and capacity constraints. Coordination between the different teams and processes is required to ensure that the production schedule is synchronized, and the necessary materials, tools, and equipment are available when needed. This helps to prevent bottlenecks and delays in the overall manufacturing process.

In conclusion, coordination between stamping and other processing processes is critical in the manufacturing of assembly parts. Proper communication, collaboration, and planning between the stamping and other processing teams are necessary to ensure that the stamped parts are manufactured to the correct specifications, compatible with other components, and fit together seamlessly during assembly. Careful consideration of design, material properties, quality control, and production planning are essential to achieve an efficient and effective manufacturing process.