Progressive Die Stamping

Progressive die stamping, also called multi-station or continuous die stamping, is a method where a single die contains several workstations. Each station performs a specific operation, like cutting, bending, or forming, as the material moves through. The material, fed in as strips, advances step-by-step through the die until a complete part is produced. This process allows multiple operations to be completed efficiently in one continuous sequence, even for complex parts.

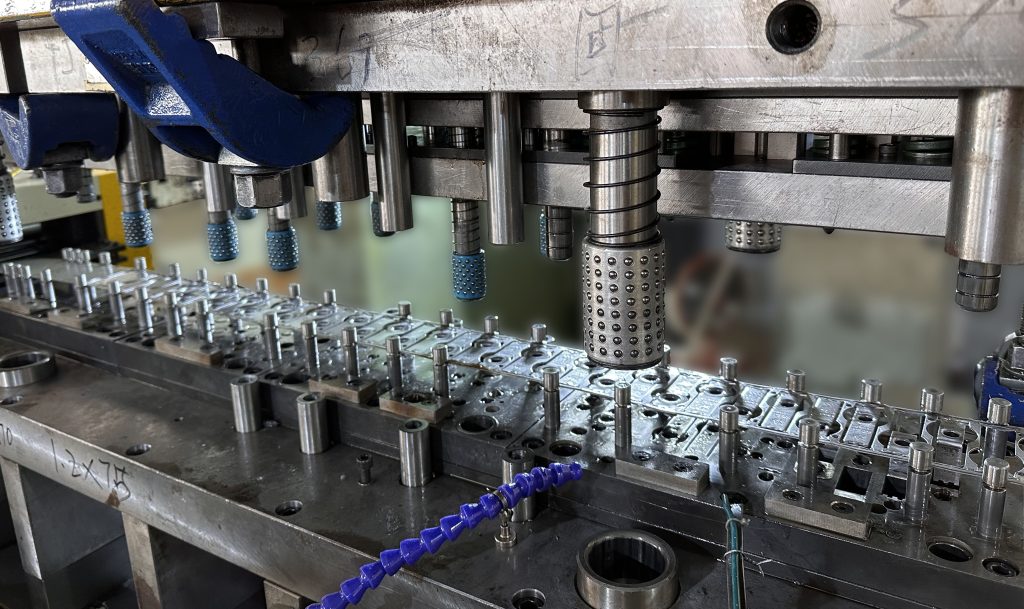

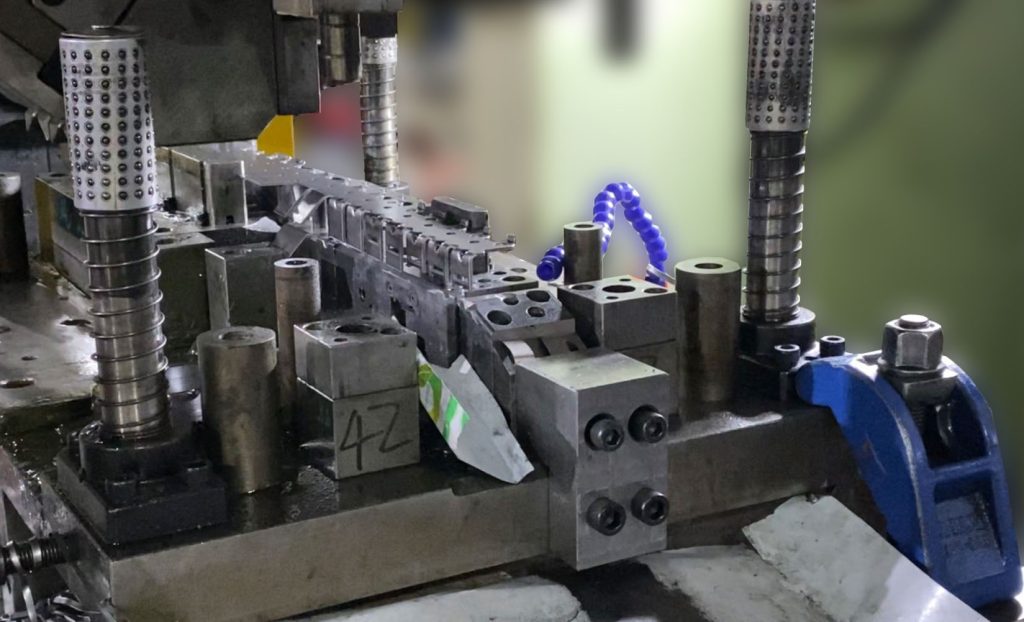

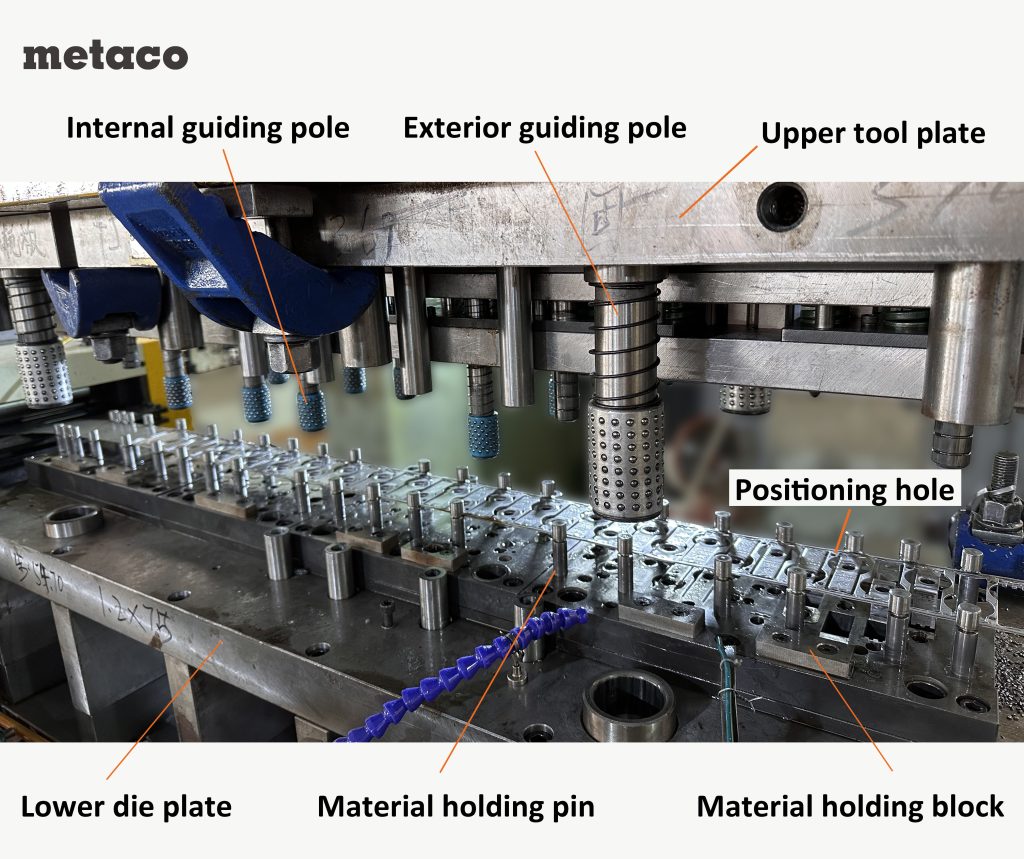

Progressive Dies case show

Components Of Progressive Die

Progressive Die Stamping is a highly efficient process used in metal forming, combining speed and precision to manufacture complex parts. This method is especially suited for producing large quantities of uniform parts. At the heart of this process are the components of the progressive die.

It consists of stripper plate, guide pin, punches and dies, feed mechanism, die block, cam units, lifters and springs, etc.

Progressive Die stamping Products

Metaco’s Advantage In Progressive Die

Progressive Die Stamping Production Costs

Progressive die stamping requires a higher upfront investment in tooling setup, but the per-part cost decreases significantly as production volume increases, offering great cost savings for large-scale manufacturing.

Progressive Die Stamping Production Volume

Progressive die stamping is ideal for high-volume production, typically exceeding 50,000 parts per year. Its continuous and automated process ensures efficient output, reducing both production time and overall costs.