Materials For Metal Stamping

Material choice is critical in stamping, as it directly impacts the quality of the final product and the efficiency of the production process. The ideal stamping material balances performance with cost, tailored to meet the specific demands of the product and the stamping technique used.

Common Stamping Materials

Steel Stamping

Brass and Copper Stamping

Aluminum Stamping

Magnesium Stamping

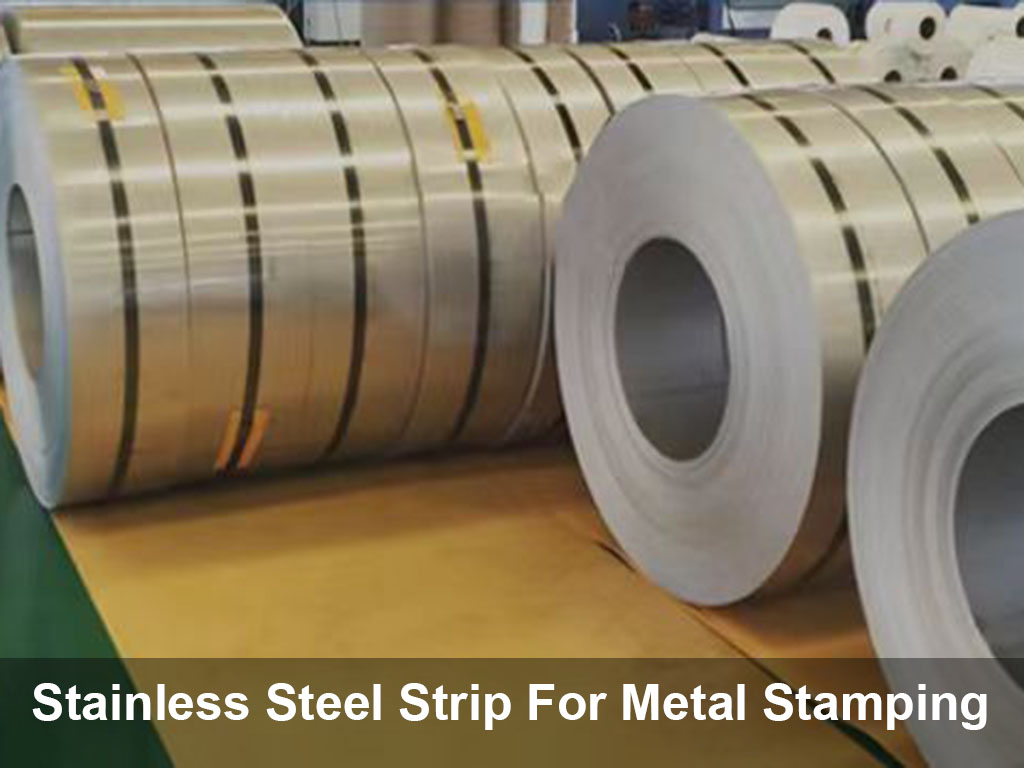

Stainless Steel Stamping

Material Selection Factors for Stamping

Based on Stamping Process

Materials must form parts without cracking or wrinkling, meeting the fundamental criteria for stamping.

Trial Stamping

Perform trial runs with materials that initially meet the requirements. Choose the material that shows no cracks and has the lowest rate of defects.

Analysis and Comparison

Compare the maximum deformability during stamping with the material’s limit of deformation allowed, based on an analysis of the material’s stamping properties.

Based on Usage of the Stamping Parts

Choose materials that meet the necessary strength, stiffness, toughness, corrosion resistance, and heat resistance required by the operating conditions of the parts.

Based on Cost-Effectiveness

Consider cost differences among materials. More affordable materials can reduce manufacturing costs but may compromise mechanical properties and machinability. Weigh the trade-offs between cost and performance to find the most economical choice.

Surface Treatment After Stamping

galvanization

electrodeposition

Stampings in different materials

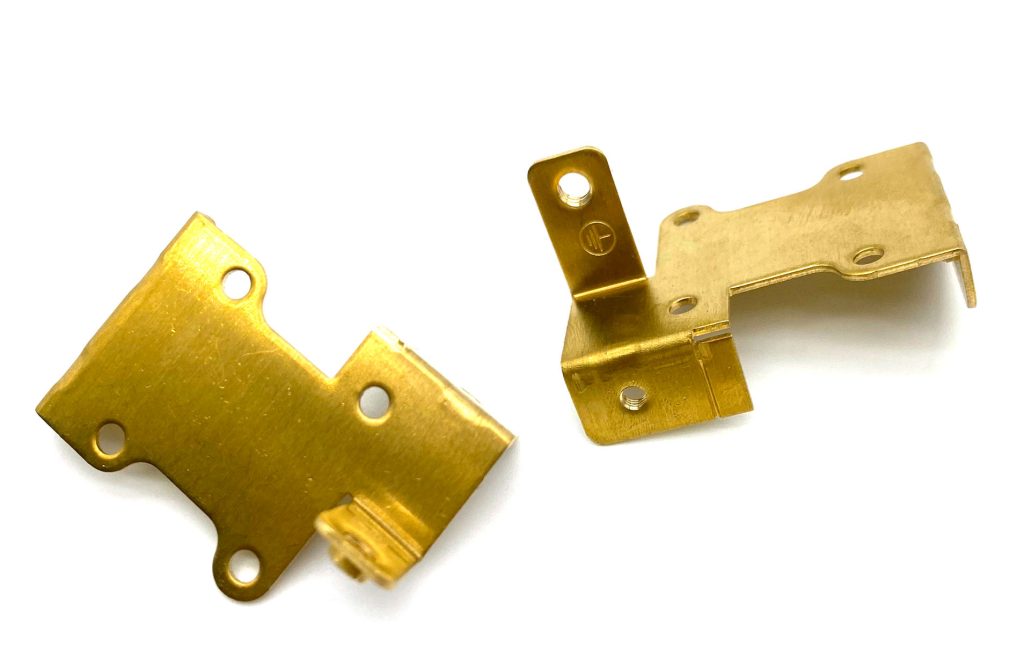

Heat Exchanger Tab

Brass

Bottle Cap For Packaging

Aluminum

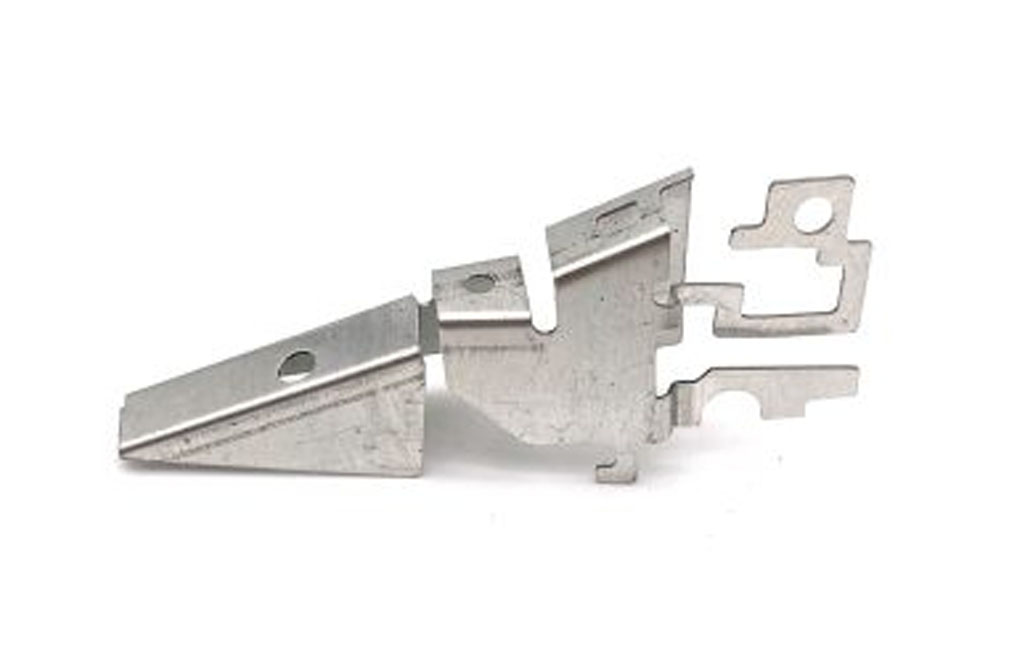

Speargun Shaft Flopper

SUS304

Floor Reinforcement Cover

SECC

Reflector Plate R Front