Fast prototyping Metal Parts

With in-house equipment, we can do welding fabrication and metal stamping tool and die manufacture by ourselves. While one company cannot do all the working processes, we cultivated partners with our partnering philosophy. With our partners who are experts in each field, we are able to do fast prototyping within short time at minimum costs.

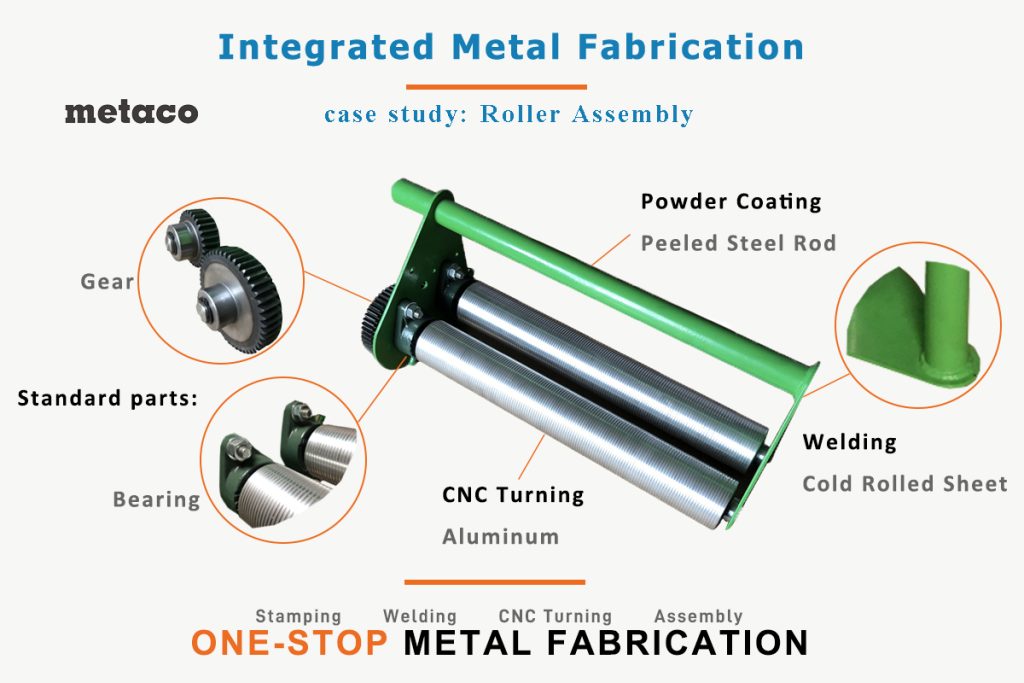

Cases For Integrated Metal Fabrication

A 15-minute radius coordination circle

At our contract manufacturing facility, we prioritize efficient coordination as the foundation of quality control. To achieve this, we’ve established a 15-minute coordination circle, which means that all of our partner suppliers are located within a 15-minute drive from our facility.

Within this radius, we can easily engage in technical discussions, conduct onsite inspections, and make regular visits as needed. Our network of coordinating suppliers, including CNC milling, powder coating, plastic injection molding, heat treating, and electroplating services, are strategically situated within this circle to ensure seamless collaboration and timely support for our manufacturing projects.

Quality first philosophy

Quality is life, this is not only a slogan, but the attitude we treat with production.

We believe quality products are just the outcome of our strict carry out of the quality management system. We use Kaizen method to improve our production process and our management takes Murphy’s law in mind for risk management due to the experience in aviation industry.

Our co-founder Ms. Lin Xiaoming is a professional quality inspector. We insist with in-process quality management to both our own factory, but core partners’ workshops as well.