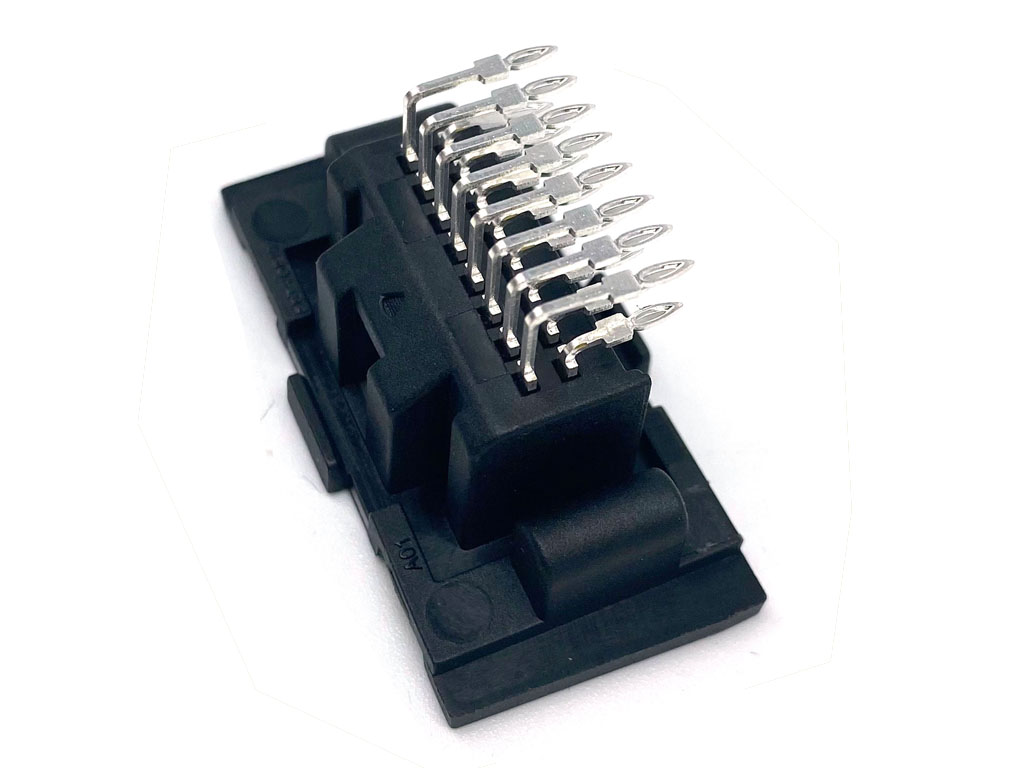

Metaco Stamping Contacts

High Productivity

We specialize in high-volume, complex stamping contact recognized by professionals across the industry, especially in high-volume and automated production, makes it highly efficient.

High-Speed Stamping

Our stamping speed can reach over 800 strokes per minute. For instance, with a 16 cavity die, we can produce 10kk contact stampings in a single day.

High Precision and Consistent Quality

Our experienced die design team excels at overcoming the technical challenges in stamping. While most companies develop contacts with a pitch of 1.0, our techniques allow us to create contacts with a pitch of 0.6mm. This enables the production of increasingly smaller, more precise parts with enhanced stability in quality.

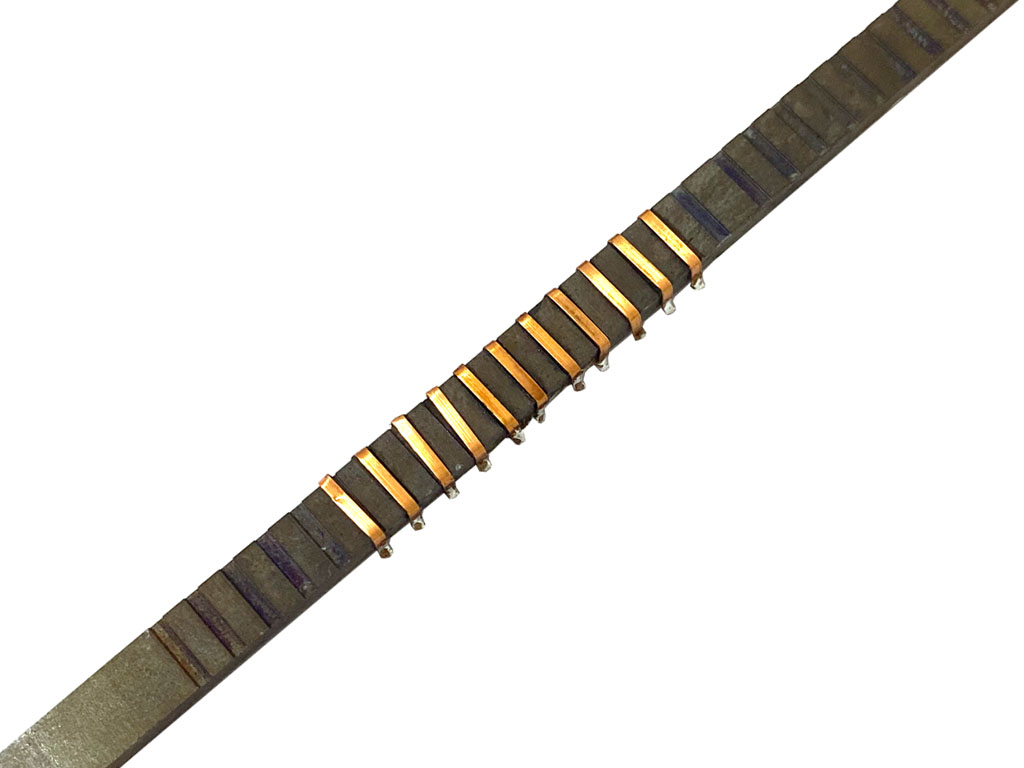

High Material Utilization

Utilizing an interlock die structure, stamping multiple contacts at once , achieving up to 18% material savings. Additionally, by increasing the speed from the standard 500 strokes per minute to 600, we help clients save both material and time costs significantly.

Materials Used in Stamping Contacts

In the manufacturing of electrical contacts, materials such as copper, aluminum, and iron are predominantly used. However, these materials are prone to oxidation, sulfuration, and other forms of corrosion when exposed to various environmental conditions. To combat this, contacts typically undergo surface treatments like electroplating

Tin Plating: Enhances solderability

Enhances solderability. Copper and other base metals often struggle with tin adhesion, but electroplating a layer of tin on the surface significantly improves the solderability of the components.

Gold or Silver Plating: Boosts conductivity

Raw materials like iron and phosphor bronze typically have conductivity rates below 20%, which may not meet the requirements for connectors with low impedance needs. Electroplating the surface with high-conductivity metals such as gold can reduce the impedance, ensuring better performance.

Applications of Stamped Contacts

Stamped contacts are versatile components widely used across various industries. Here are some of their key applications.

Electronics

Contacts are extensively used in devices like electronic instruments, audio equipment, televisions, and computer motherboards. Miniature contacts designed for limited space in electronics.

Automotive Industry

Automotive circuits are often exposed to vibrations, moisture, and high temperatures. Contacts in automotive manufacturing connect engine sensors, batteries, starter systems.

Renewable Energy

In the solar and wind energy sectors, contacts connect cables to solar panels and wind turbines. Their excellent conductivity is crucial for maximizing energy conversion efficiency.

Industrial Equipment

Industrial machinery and devices require extensive electrical connections, and contacts are ideal for these needs. They are commonly used to connect motors, sensors, control panels.